Prism piece and backlight mould

A technology of backlight module and prism sheet, applied in prisms, optics, electric light sources, etc., can solve the problem of inconspicuous display effect, and achieve the effect of improving light condensing effect, improving performance index and preventing moire pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

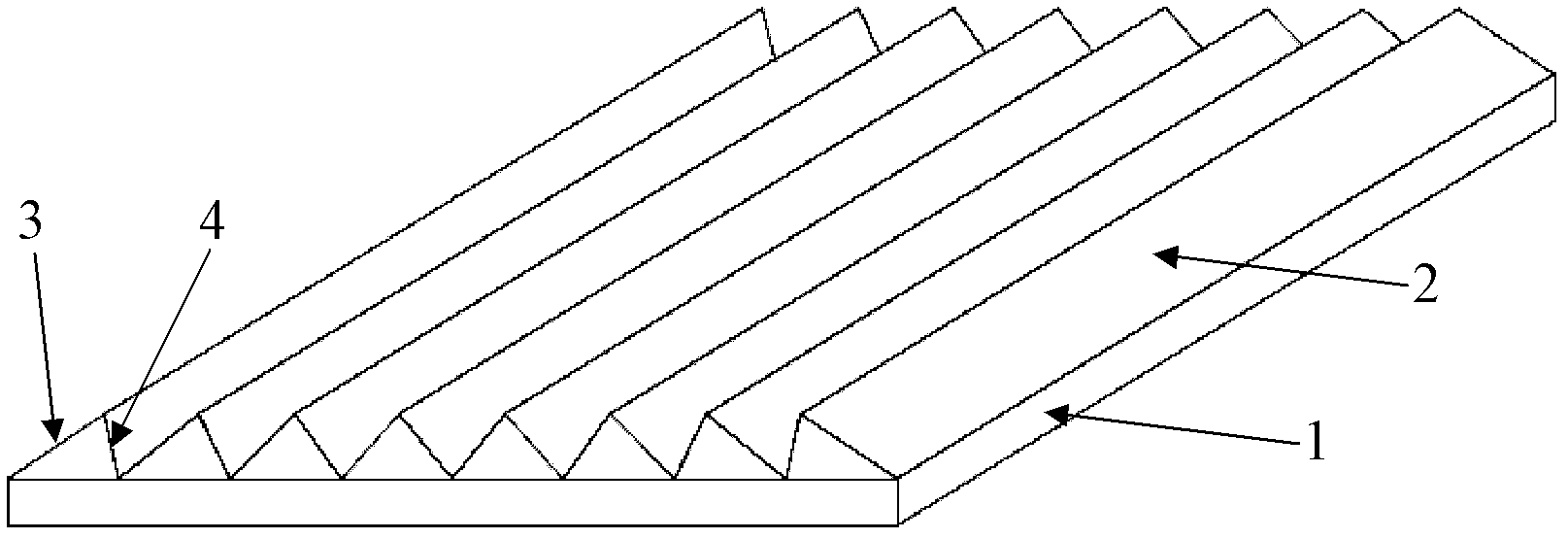

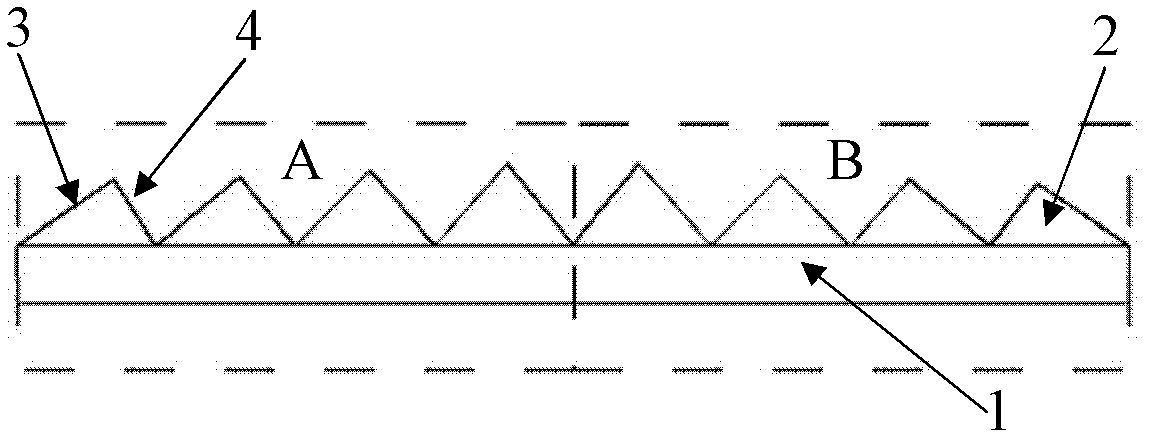

[0034] This embodiment introduces the structure of the prism sheet for the purpose of being used for the backlight source of the flat panel display. figure 1 A schematic structural view of the prism sheet of this embodiment is shown, figure 2 is its side view. The prism sheet includes a main body 1 and a plurality of prisms 2 on the main body 1 . The upper surface of the main body 1 is rectangular and has a symmetry axis (not shown in the figure), which divides the upper surface of the main body 1 into a first area A and a second area B which are symmetrical to each other. The prisms 2 and the prisms 2 of the second region B are mutually symmetrical about the axis of symmetry. The prism 2 in the present embodiment preferably has a triangular cross section, the bottom surface of the prism 2 is connected to the upper surface of the main body 1, and the remaining two sides are respectively marked as the first side 3 and the second side 4, on the first area A , the first side ...

Embodiment 2

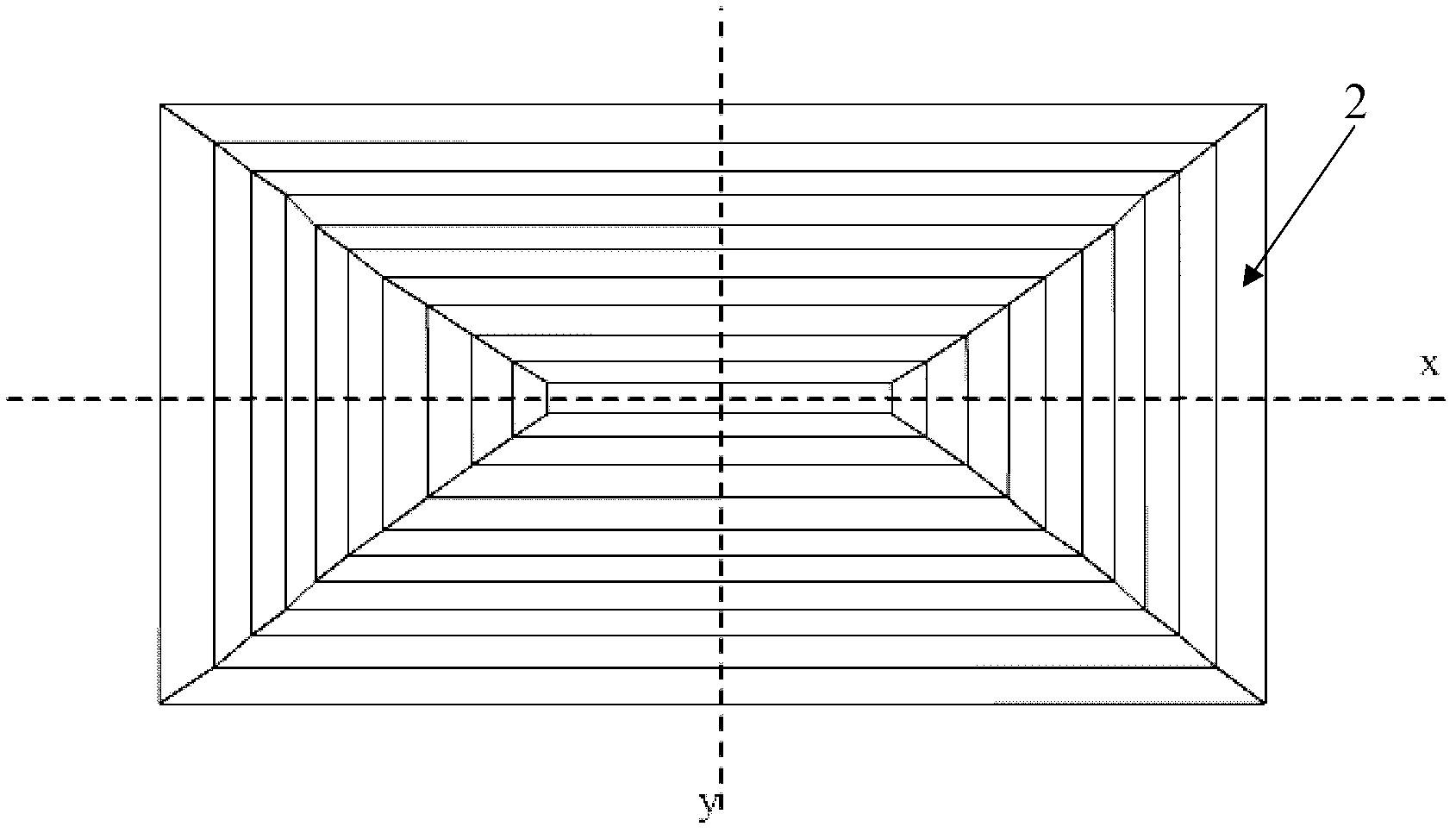

[0044] image 3Shown is the top view of the prism sheet of this embodiment. The prism sheet of this embodiment also includes a main body 1 and a prism 2 positioned on the main body 1. The difference from Embodiment 1 is that the prism 2 of this embodiment is frame-shaped Each frame of the frame-shaped prism is parallel to each edge of the main body 1 respectively, that is, the shape of the frame-shaped prism is similar to that of the main body 1 . In order to adapt to the rectangular shape of the flat panel display, the frame shapes of the main body 1 and the prism 2 are both rectangular, and a plurality of prisms 2 are nested on the upper surface of the main body 1 to form a nested "back" structure.

[0045] In this embodiment, the arrangement structure of the different sides of each prism 2 is similar to Embodiment 1, as Figure 5 shown. In the "back"-shaped prism structure, the prism 2 in the center of the main body 1 can be replaced by a strip prism with a triangular cro...

Embodiment 3

[0048] This embodiment provides a backlight module, which has the prism sheet in Embodiment 1 or Embodiment 2.

[0049] In this embodiment, the prism sheet is connected with the light guide plate, and the prism unit is arranged on the light guide plate, so that the prism on the prism sheet can be engaged with the prism unit on the light guide plate. After the prism sheet is connected with the light guide plate, the surface of the main body of the prism sheet Parallel to the surface of the light guide plate, not only can avoid the scratch of the prism sheet, but also facilitate the assembly of the device.

[0050] It can be seen from the above embodiments that the embodiment of the present invention sets the inclined structure of the prism, which can improve the light-gathering effect of the prism sheet in a local area, and can improve the overall performance index of the backlight by applying it to the backlight of a flat panel display. , so as to improve the brightness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com