Electronic paper display device and manufacturing method thereof

A technology for display devices and manufacturing methods, which is applied to electrical components, electrical components, static indicators, etc., can solve the problems of high difficulty in driving control, difficulty in two-color or color display, and difficulty in stabilizing display particles, and achieve easy two-color or color display. Display, reduce species, motion control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

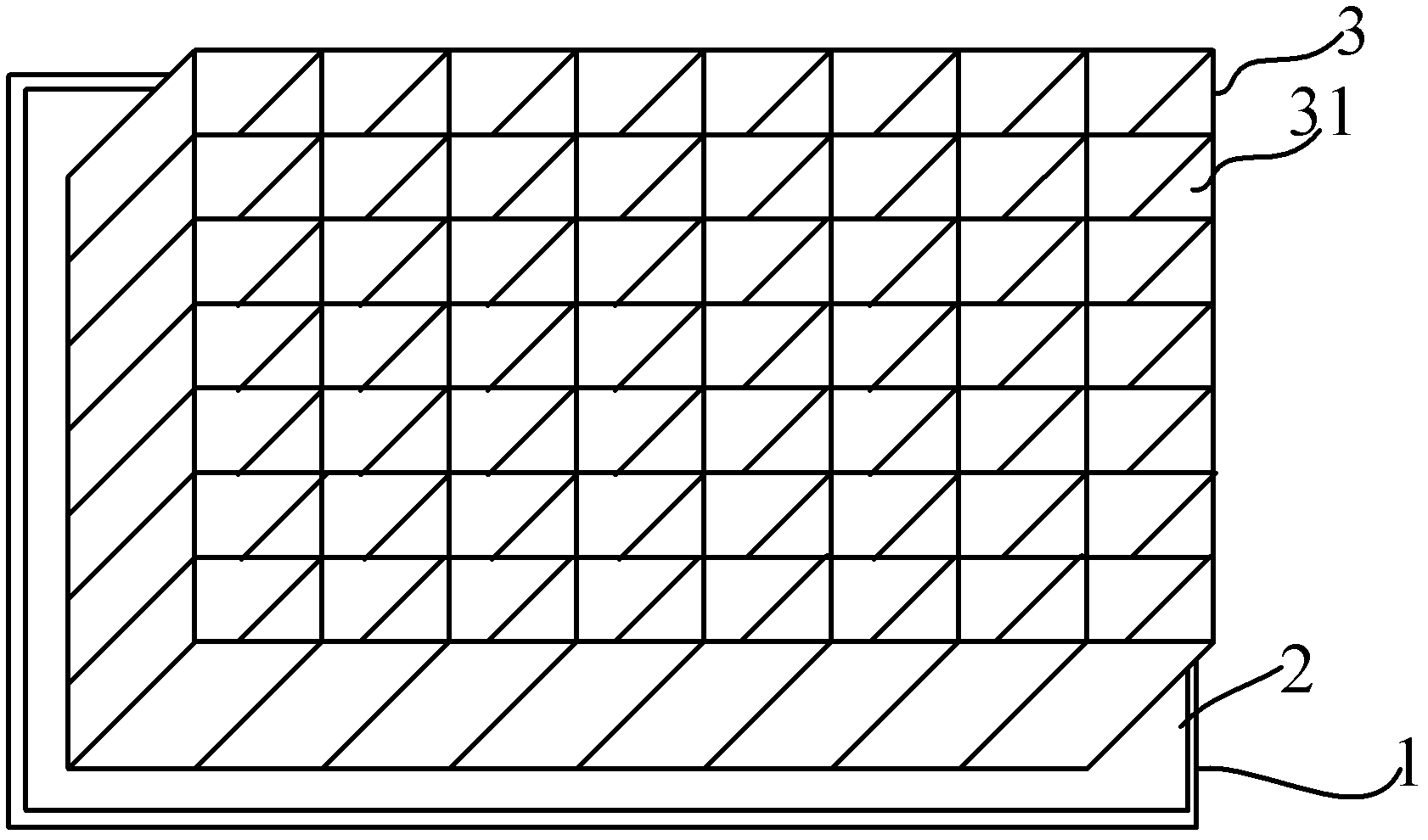

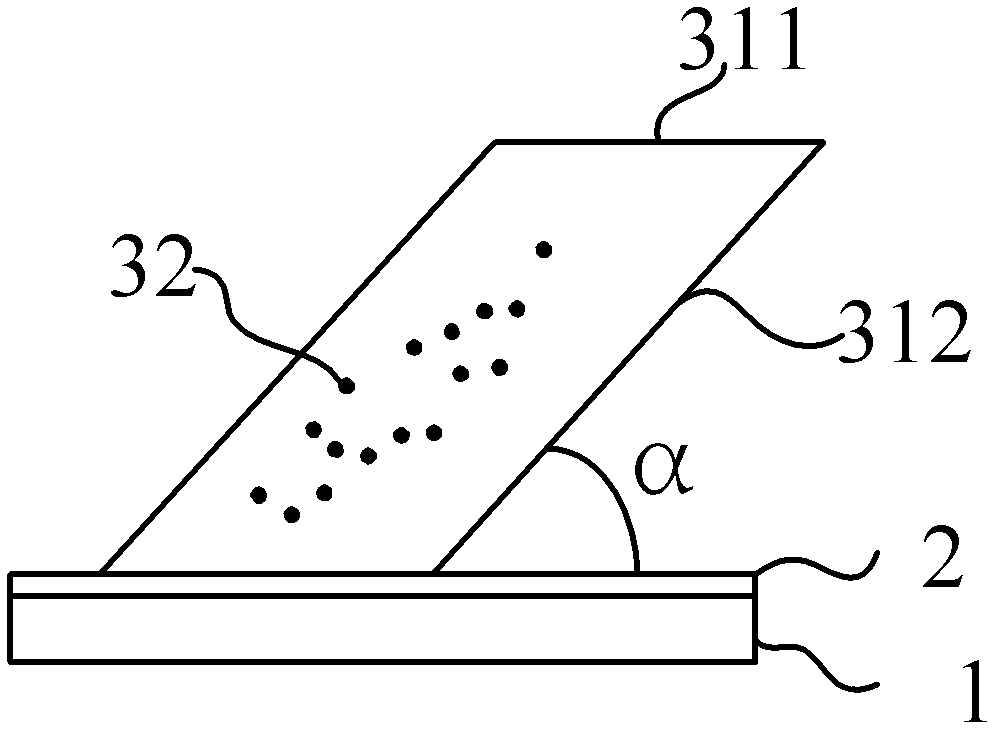

[0040] In this embodiment, the colors of the inclined microholes 31 are the same, and electrophoretic display particles of one color are arranged in each inclined microhole 31, and the color of the electrophoretic display particles in each inclined microhole is the same as that in other inclined microwells, Thereby realizing two-color display.

[0041] For example, the inclined microholes 31 are all white, and black electrophoretic display particles 32 are enclosed in each inclined microhole 31 , so as to realize black and white two-color display.

[0042] For example, the inclined microholes 31 are all black, and white electrophoretic display particles 32 are enclosed in each inclined microhole 31 , so as to realize black and white dual-color display.

[0043] For example, the inclined microholes 31 are all single colors such as black, white, blue, green, red, yellow, etc., and the electrophoretic display particles 32 in each inclined microhole 31 can also be black, white, bl...

Embodiment 2

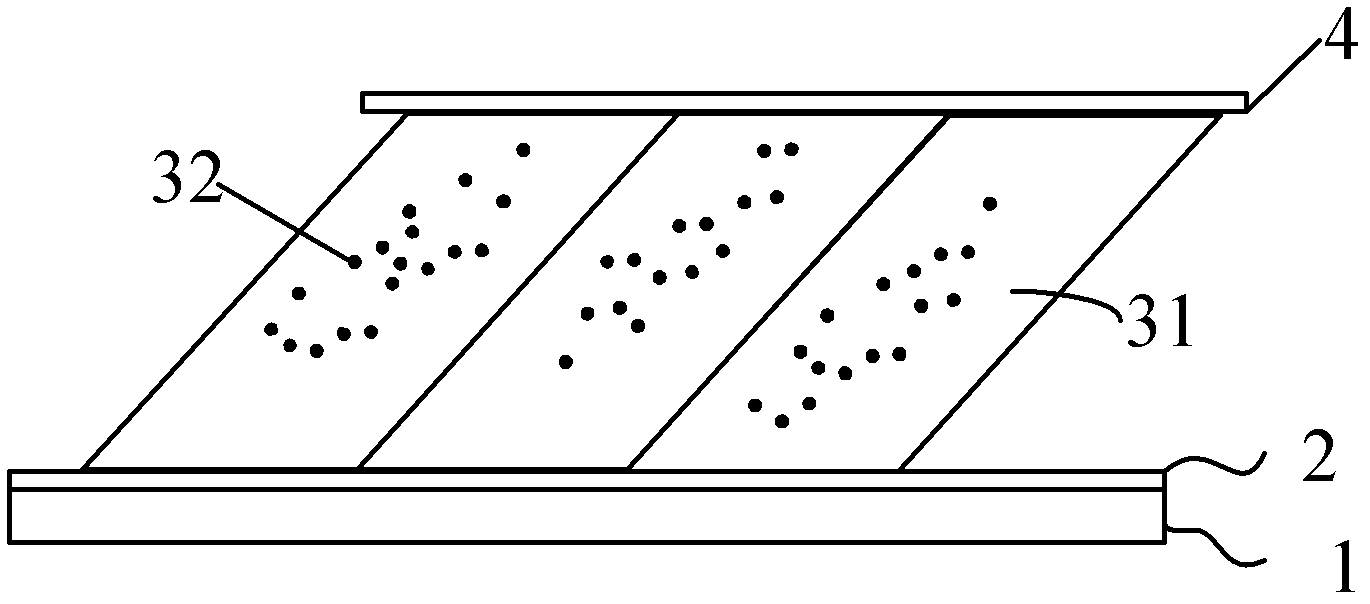

[0047] In this embodiment, the inclined microholes 31 have the same color, and each inclined microhole 31 is provided with electrophoretic display particles of one color to realize color display.

[0048] Specifically, a display principle similar to that of a liquid crystal display can be used, and a display unit is arranged in the inclined microporous layer 3, and the display unit includes at least two successively adjacent inclined microholes 31, and the at least two successively adjacent inclined micropores Electrophoresis in the wells shows that the particles are of different colors.

[0049] For example, if Figure 4 As shown, the inclined microholes 31 are black K, and a display unit 33 is arranged in the inclined microporous layer 3. The display unit 33 includes three successively adjacent inclined microholes 31, and the three successively adjacent inclined microholes 31 The electrophoresis shows that the colors of the particles 32 are different, namely red R, green G,...

Embodiment 3

[0053] In this embodiment, similar to the second embodiment, the color of the inclined microholes 31 is used to achieve colorization.

[0054] Specifically, a display principle similar to that of a liquid crystal display can be used, and a display unit is provided in the inclined microporous layer 31, and the display unit includes at least two successively adjacent inclined microholes, and the at least two successively adjacent inclined microholes The colors are different.

[0055] For example, if Figure 5 As shown, the inclined microporous layer 3 is provided with a display unit 33, and the display unit 33 includes three successively adjacent inclined microholes 31. The colors in the three successively adjacent inclined microholes 31 are different, namely red R , green G, and blue B, and the three inclined microholes 31 include electrophoretic display particles 32 of the same color, such as white or black, or other colors.

[0056] Of course, the colors of the electrophore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com