Cylindrical structure and method of production thereof

A structure and cylinder technology, applied in the field of propulsion devices, can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

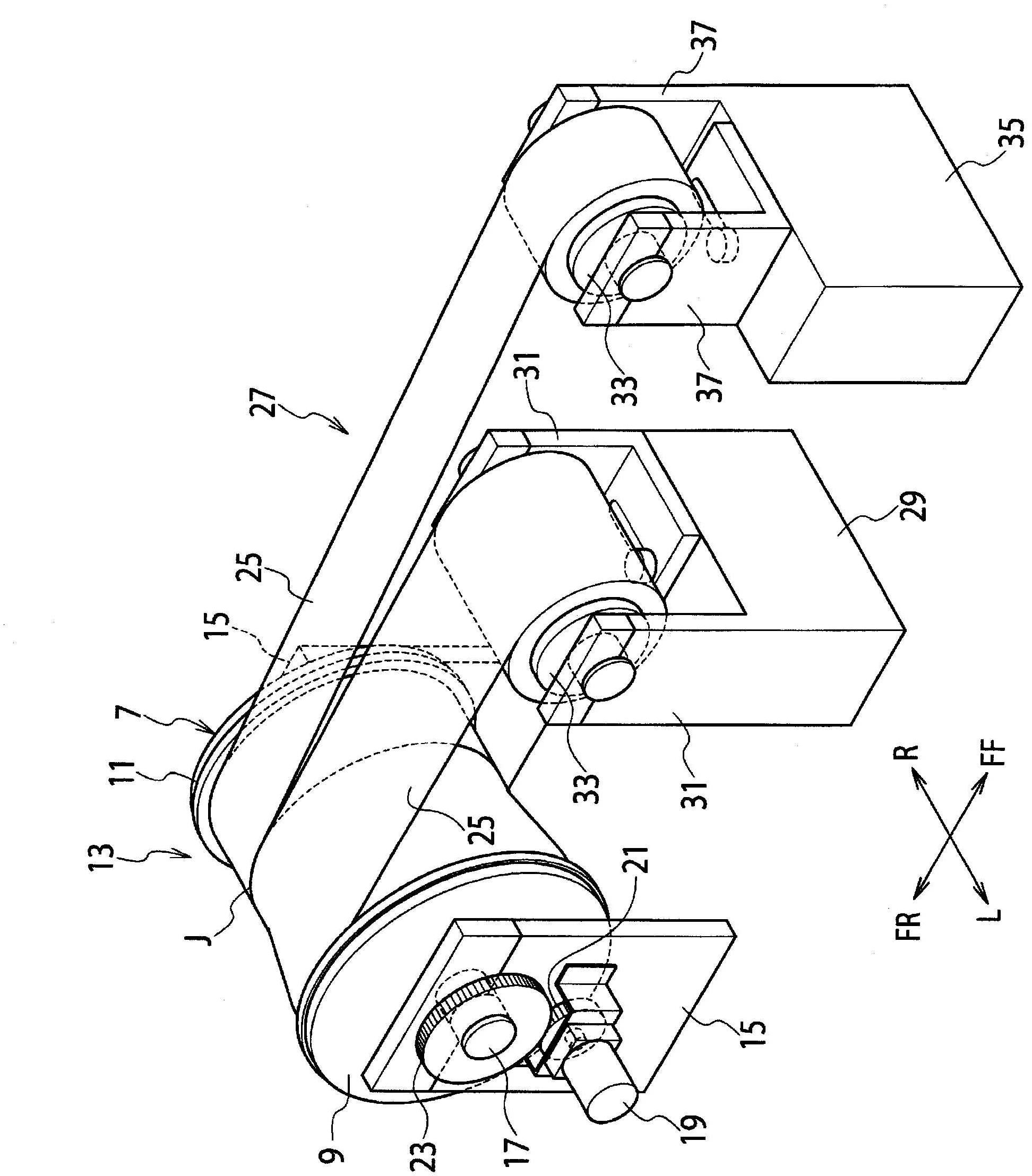

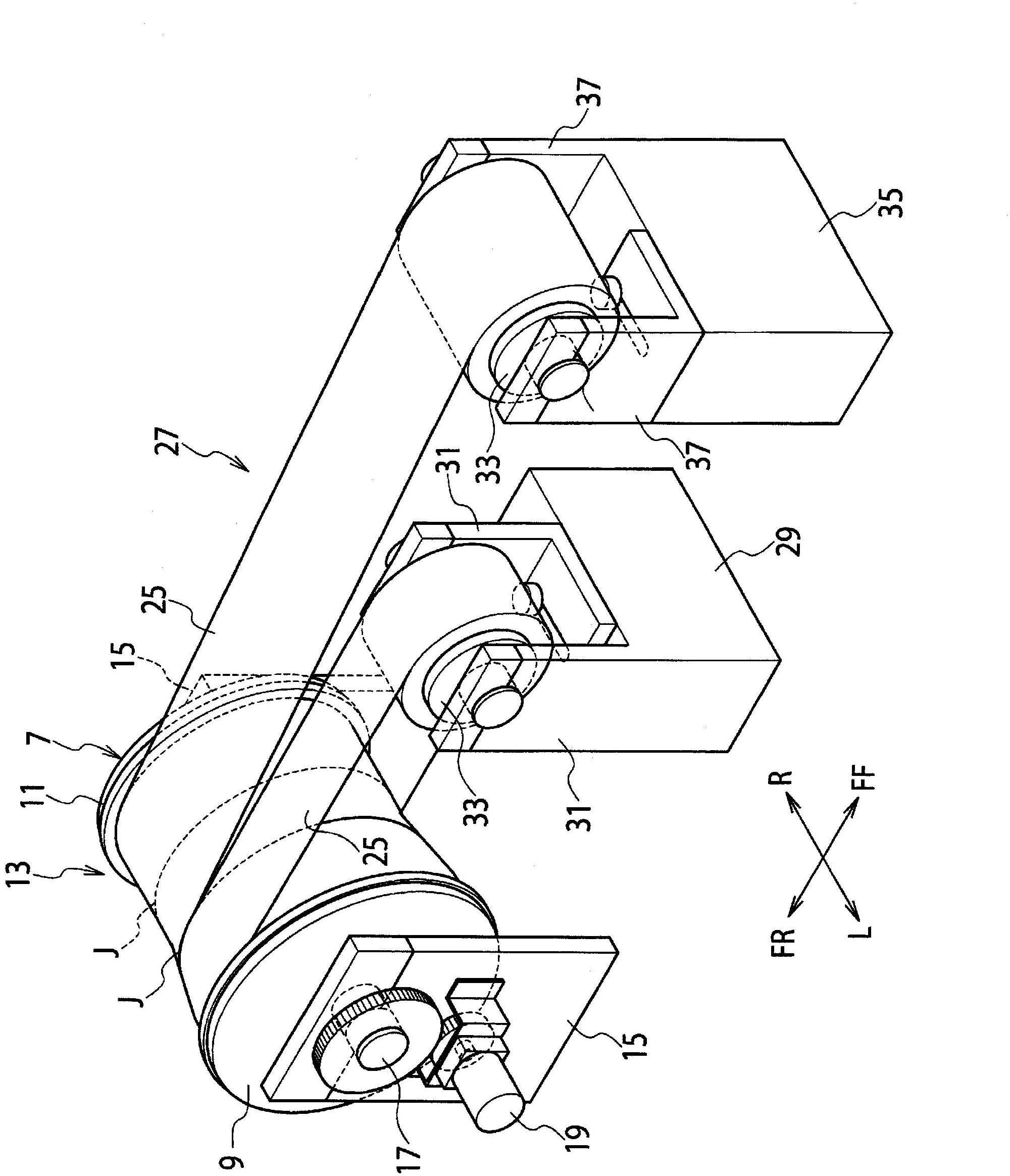

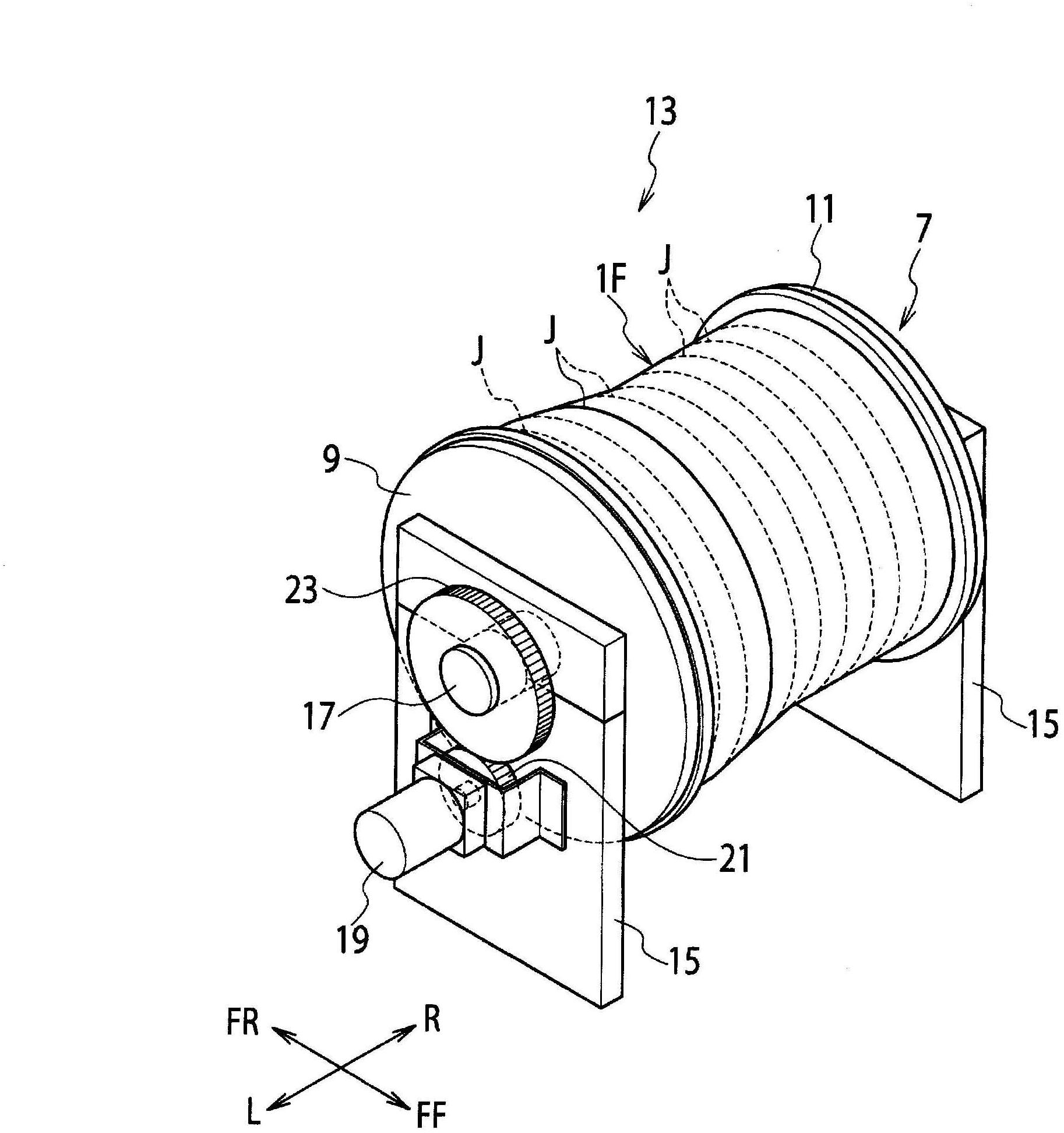

[0017] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0018] For ease of description, the directions shown as L and R in the accompanying drawings are respectively expressed as left and right, and the directions shown as FR and FF are respectively expressed as backward and forward, but these expressions are non-limiting for the present invention of.

[0019] The manufacturing method of this embodiment can be applied as an example in Figure 7 Manufacture of fan shrouds for jet engines of aircraft shown in . The engine 3 generally includes an engine main body and an engine nacelle surrounding and supporting the engine main body, and the engine main body includes a fan 5 . The nacelle includes a plurality of cowling components, each cowling component being substantially symmetrical about an axis. Among the cowl parts, the part surrounding the fan 5 is the fan cover 1 . The fan cover 1 has a substantially cylindrical shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com