Automatic multi-stage countercurrent extraction method of tea infusion

A countercurrent extraction and automatic extraction technology, applied in the field of beverage processing, can solve the problems of poor quality of tea juice, low concentration of tea juice, and low extraction efficiency, and achieve the effects of less labor, stable equipment operation, and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

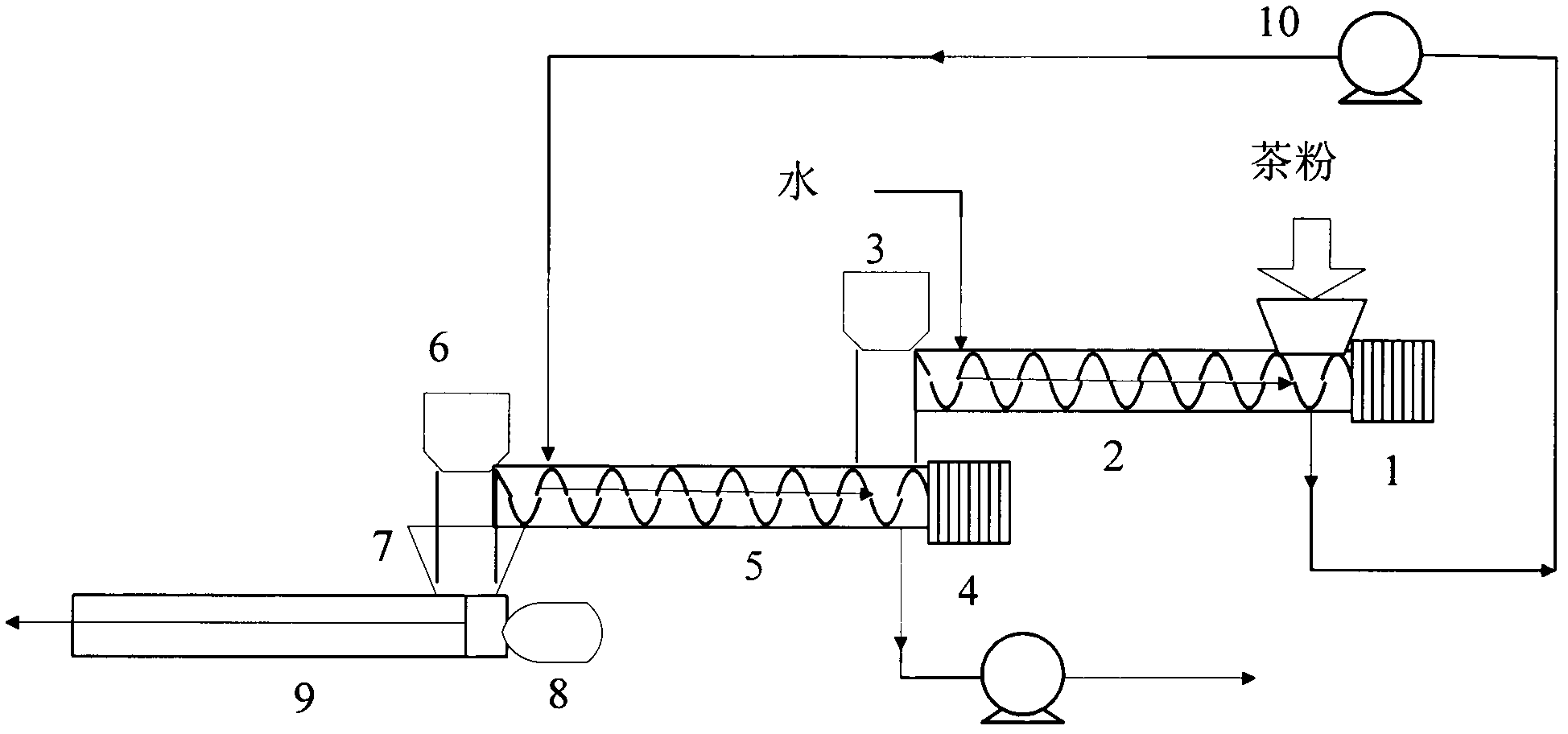

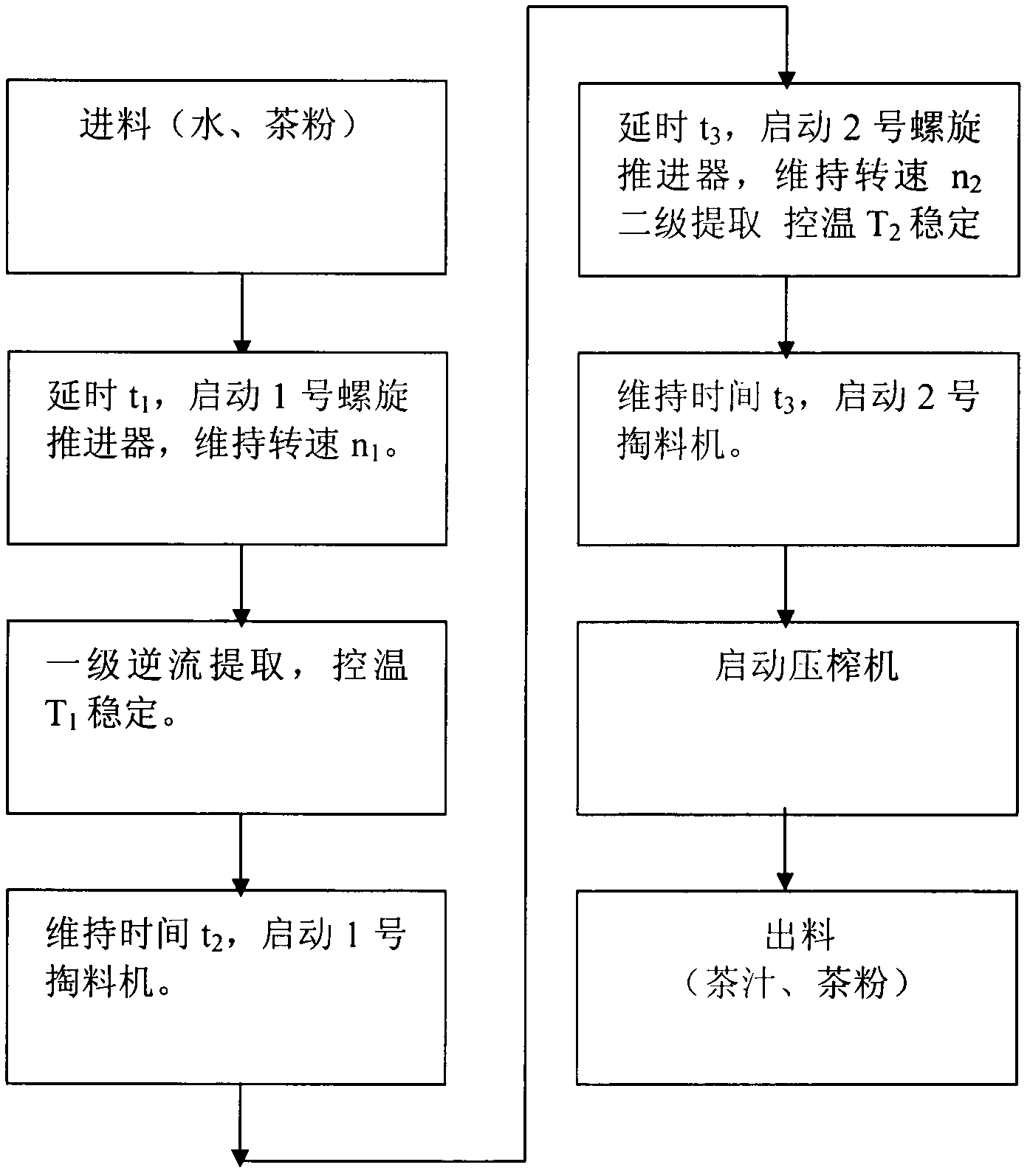

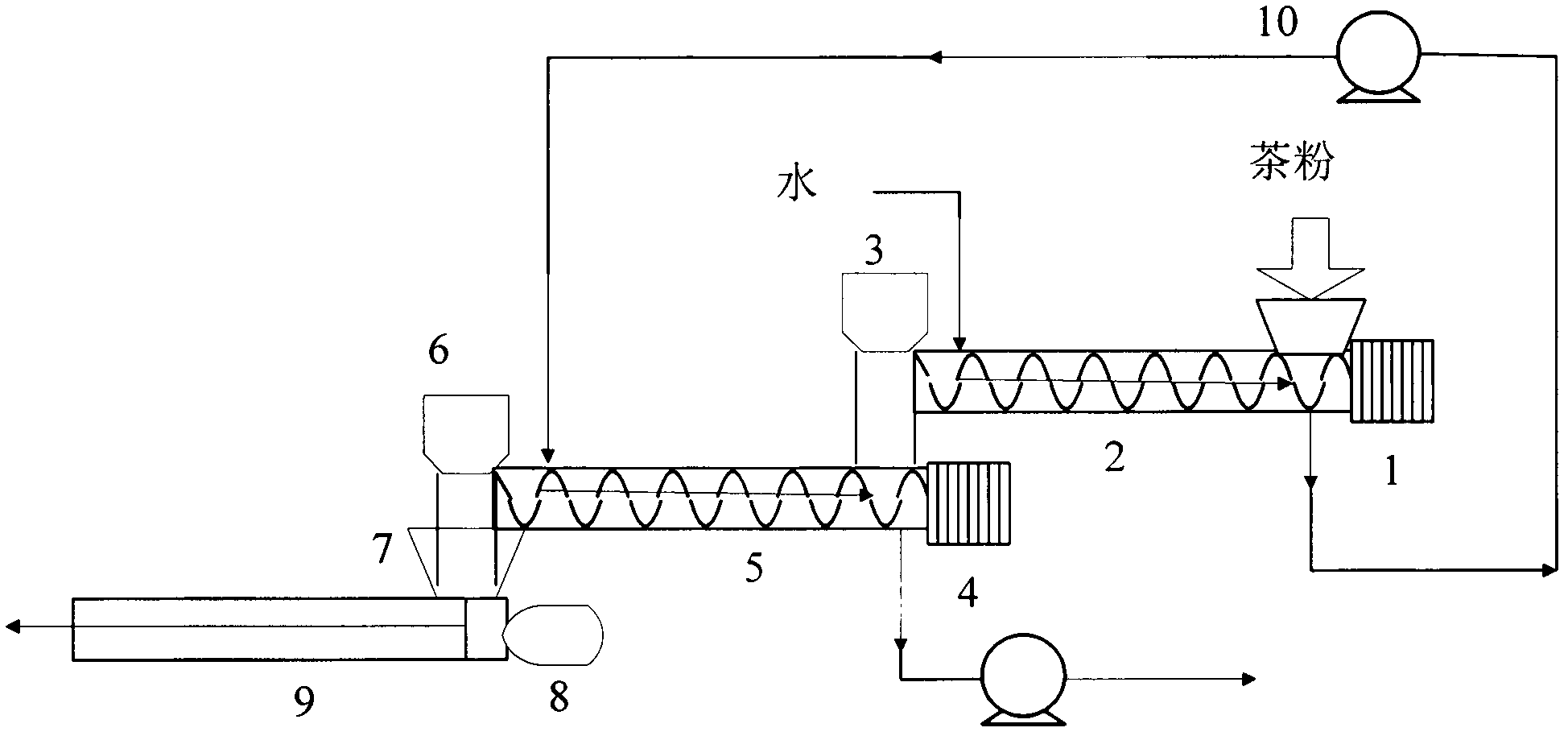

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] (1) Primary extraction: add softened water at 45-60°C at the water inlet, and the power of the water inlet is provided by a pipeline pump installed at the water inlet. When the water flow is stable, turn on the No. 1 screw propeller to make the tea powder (Entered from the feed end) flows to the No. 1 digging machine, and forms a countercurrent with the demineralized water. Because the propeller is spiral, the extraction tank can be divided into many small spaces, thus slowing down the flow rate of the water and prolonging the demineralized water and demineralized water. The contact time of tea powder, wherein, the No. 1 extraction tank maintains the water temperature T 1 constant, No. 1 screw propeller maintains propulsion speed n 1 constant.

[0014] (2) Secondary extraction: A 90° angle is formed between the pipeline connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com