Active-carbon-containing midsole, insole, particle and preparation method

A technology of activated carbon particles and a production method, which is applied to insoles, shoe soles, footwear, etc., can solve the problems of easy generation of dust, reduced adsorption capacity of activated carbon, and low plasticity of activated carbon, so as to increase the area and cycle, enhance the deodorization effect, and prolong the life of the product. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

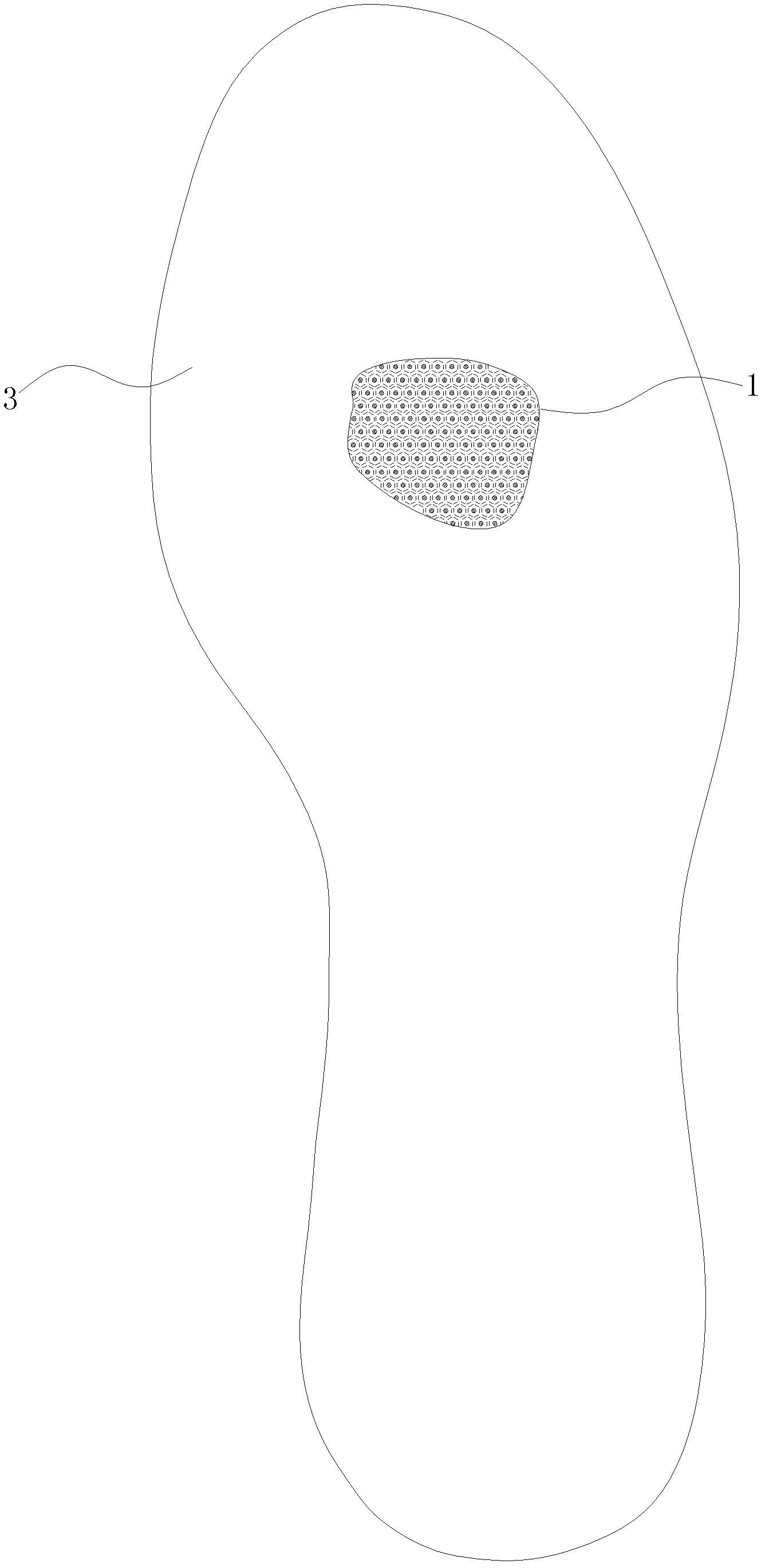

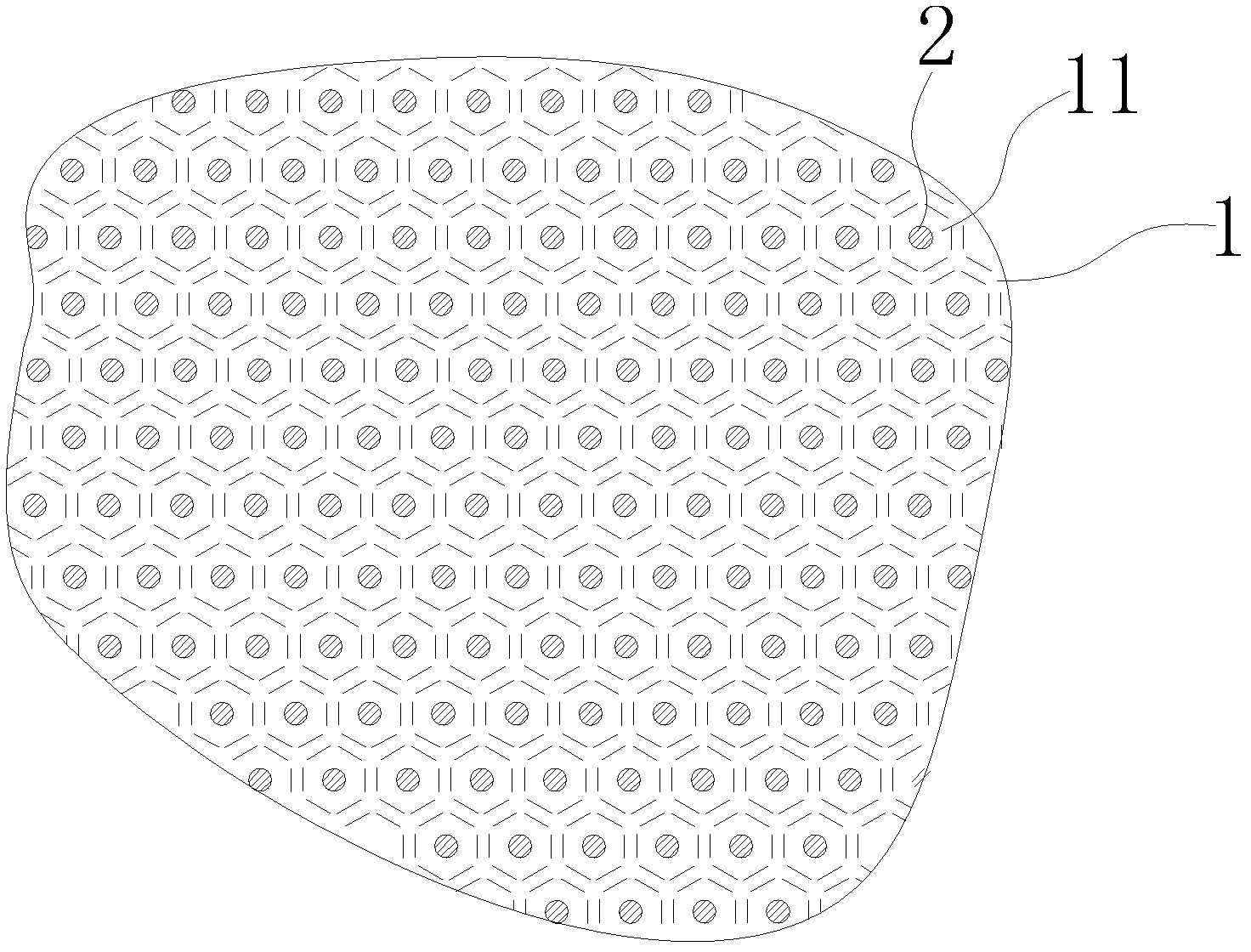

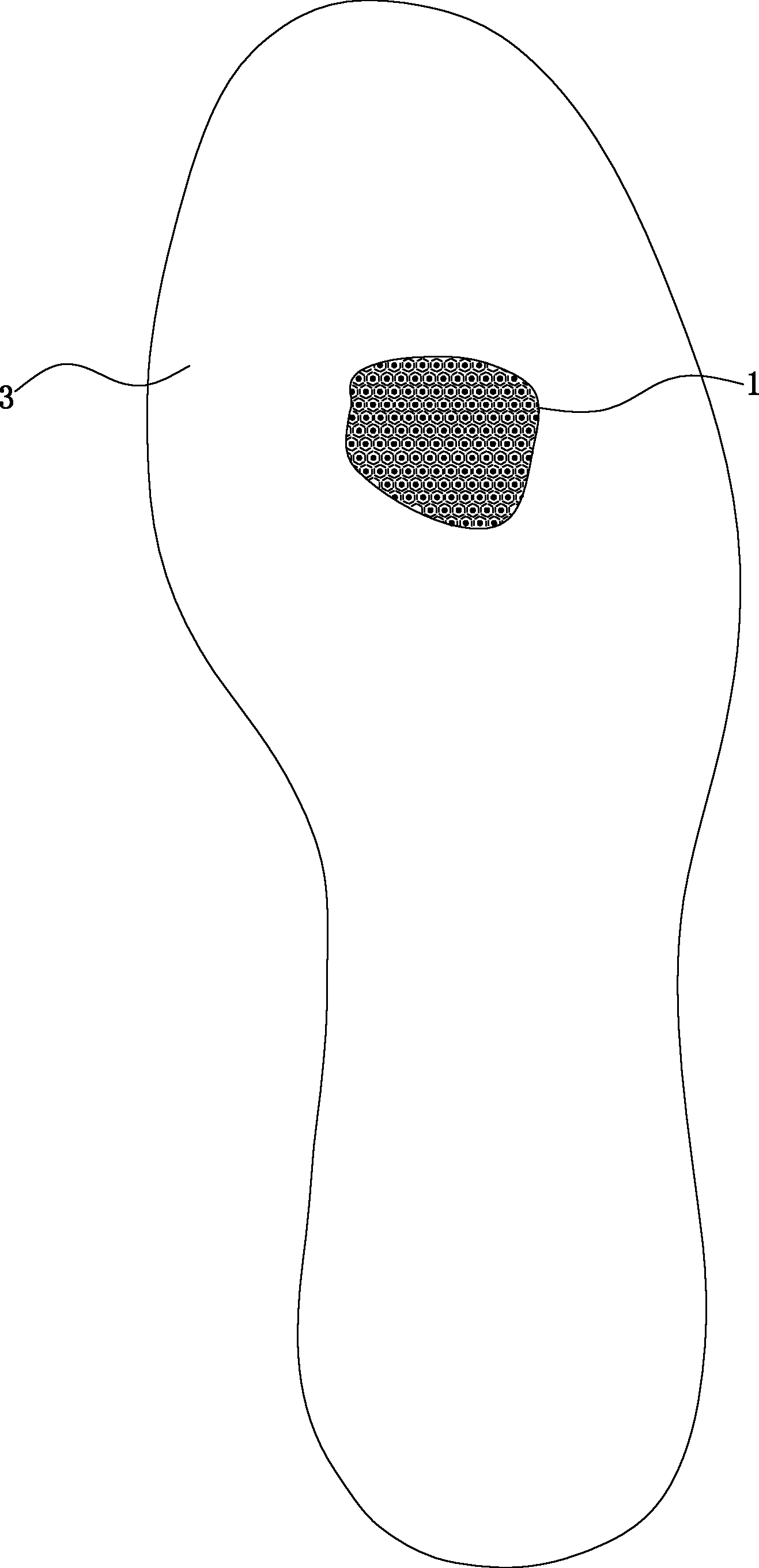

[0034] Such as figure 1 As shown, it is an insole of the present invention, which includes a matrix 1 and a plurality of activated carbon particles 2, wherein the shape of the matrix 1 conforms to the shape of the sole of the human body, the matrix 1 is in the shape of a sponge, and the activated carbon particles 2 are respectively located in the pores of the sponge body 11 , the sponge body pores 11 are evenly distributed on the base body 1 , therefore, the activated carbon particles 2 are also uniformly arranged in the base body 1 , and the sponge body pores 11 are connected to the surface of the base body 1 .

[0035] The above-mentioned insole is placed on the sole of the shoe. When the user wears it and steps on the base 1, the base 1 shrinks along the thickness direction, and the sponge pores 11 inside are compressed. When people lift their feet, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com