Leaf spring assembly line

An assembly line and flow technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of no automatic assembly line, low production work efficiency, affecting work efficiency, etc. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

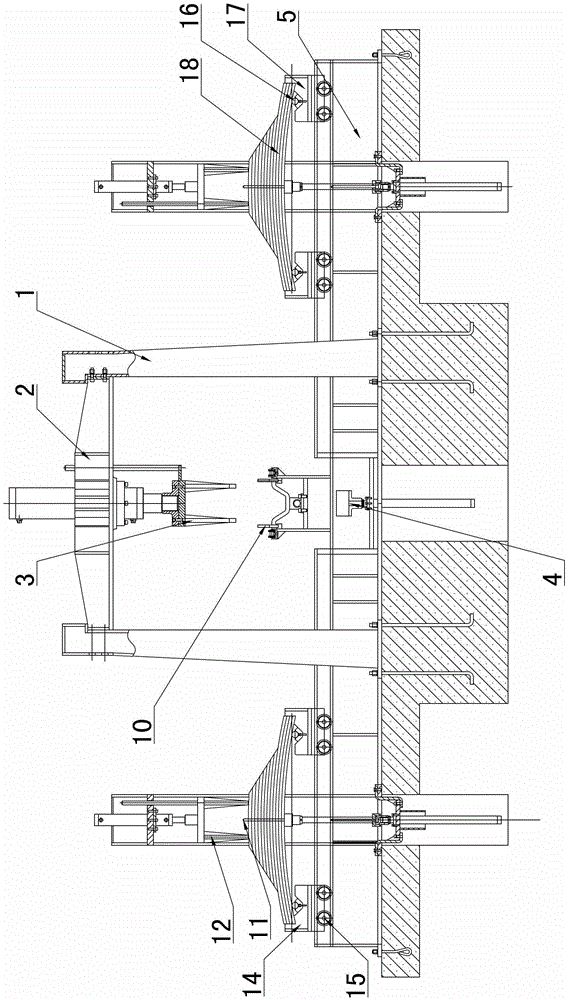

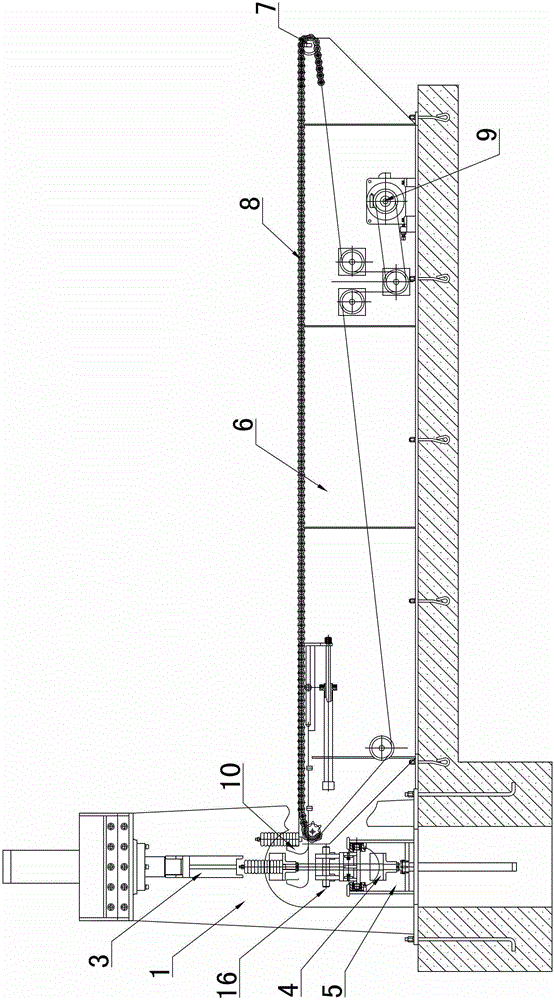

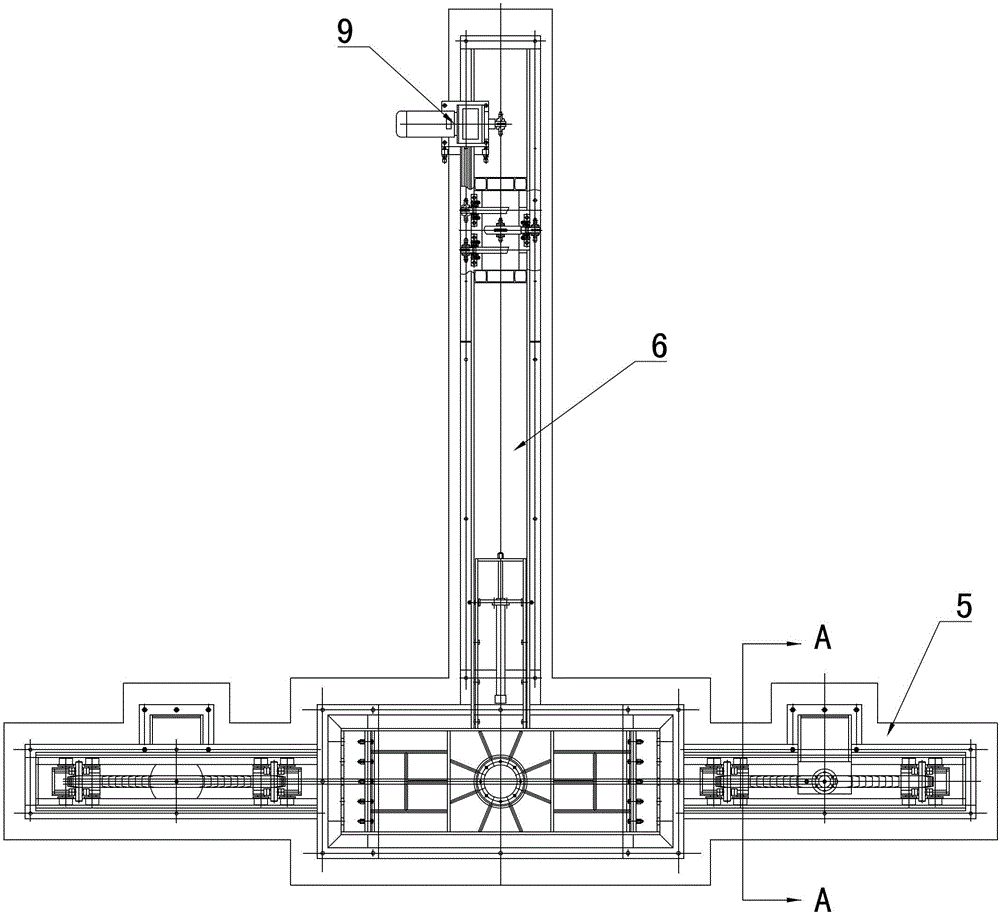

[0022] Refer to attached figure 1 : This a kind of leaf spring flow assembly line includes assembly bracket 5, frame, card loading assembly and chipping device. The assembly bracket 5 is fixed horizontally, and the vertical assembly bracket 5 is installed with a vertical rack and a horizontal clamping assembly at the middle position of the assembly bracket 5, and a chip device is fixedly installed at both ends of the assembly bracket 5, and the upper plane of the assembly bracket 5 is slidingly installed Multiple sets of preloading trolleys. The multi-leaf reeds 18 are assembled on the chipping devices at the two ends of the assembly bracket 5, and the central bolt is threaded and tightened, preloaded on the middle frame, and the clip bolts are installed on the clamping assembly, and the reeds 18 are corrected and checked. become.

[0023] The frame includes two vertically fixed frame columns 1 and a beam 2 supported above the frame column 1. A pressure head 3 that can move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com