Structure of double colored plastic injection molding machine and process modification thereof

A two-color injection molding machine and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of high purchase cost, difficult manufacturing and processing, and high maintenance requirements of two-color injection molding machines, and achieve simplification of the injection molding process, improvement of efficiency, and savings in injection molding the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

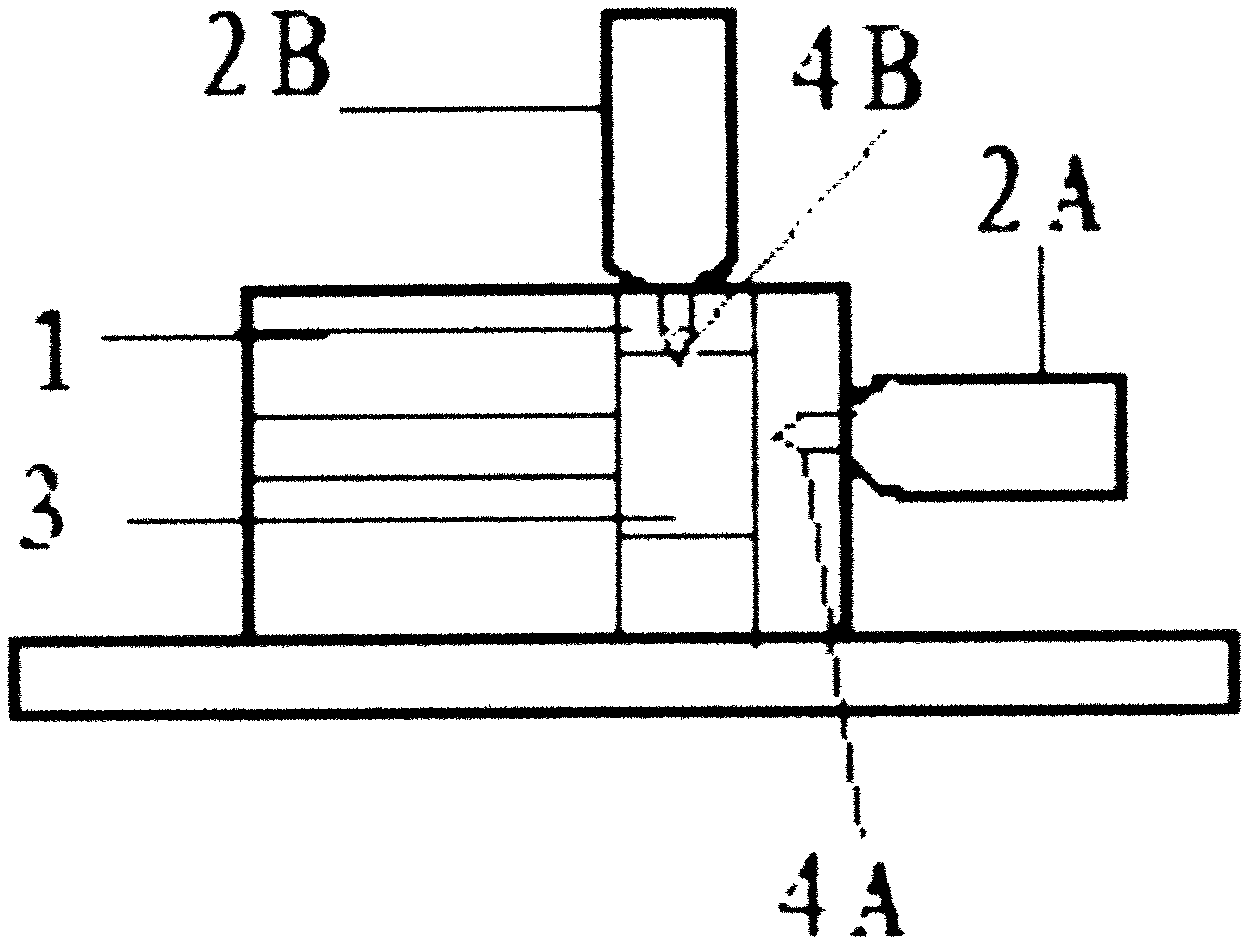

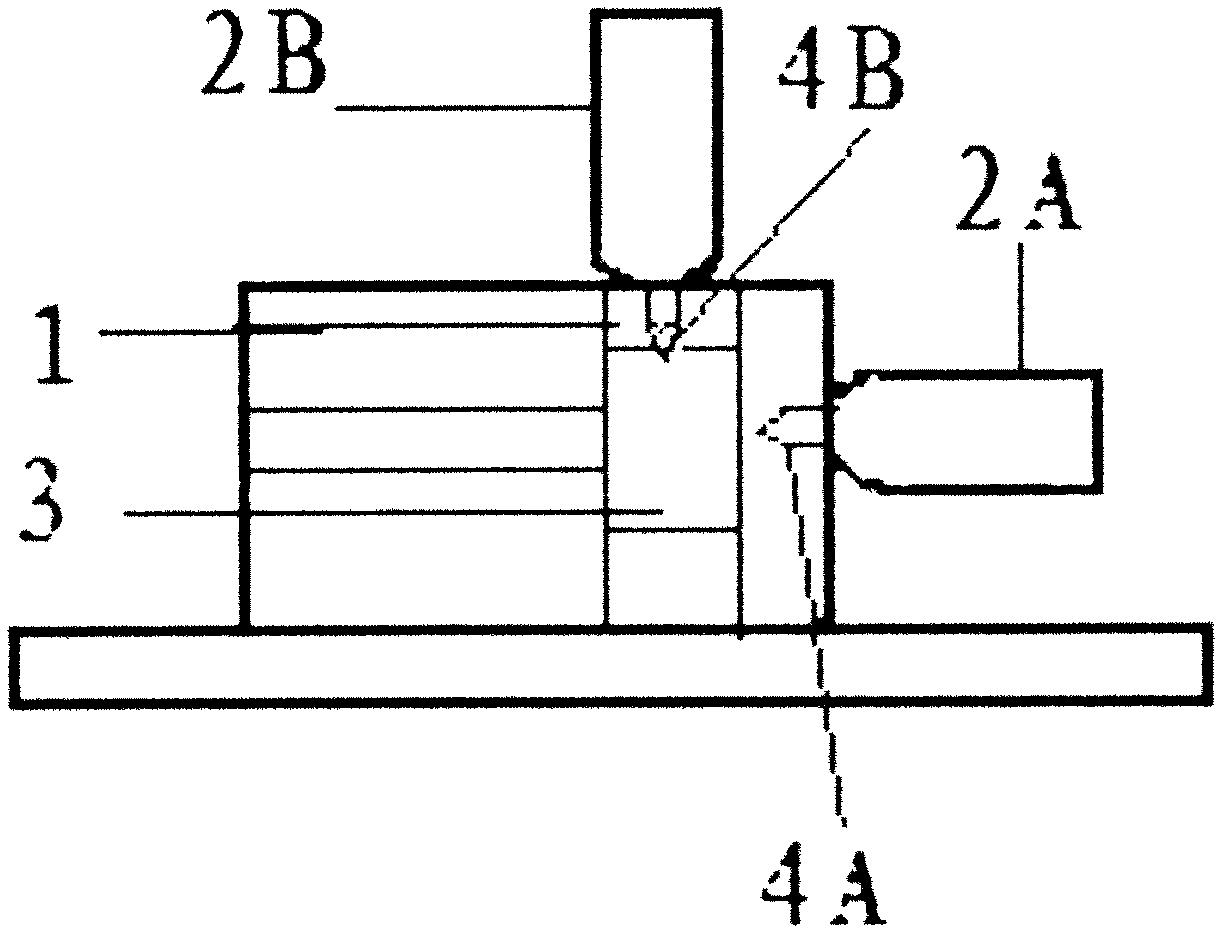

[0009] In order to make the technical solution of the present invention clearer, the following reference figure 1 Examples are given to further illustrate the present invention in detail.

[0010] The structure of a two-color injection molding machine of the present invention and its process correction includes a mold clamping mechanism 1, injection devices 2A and 2B, and a mold 3 specially configured for this purpose: a mold clamping mechanism 1 is provided between the fixed template and the movable template The fixing device is used to fix the mold 3, the injection devices 2A and 2B, the injection devices 2A and 2B are formed by connecting the barrel with the injection nozzles 4A and 4B respectively, the injection nozzles 4A and 4B can be advanced and retreated, and the injection device 2A and Ordinary injection molding machine has the same installation position, installed on one side of the injection molding machine, with the nozzle 4A head facing the mold and at the same leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com