Lateral reinforcing structure in whole lifting of plane steel truss and whole lifting method

A technology for overall lifting and strengthening of structures, applied in building construction, building material processing, construction, etc., can solve the problems of prone to torsional structure internal stress, deviation from hoisting position, poor lateral stability of large-span structures, etc. The effect of removing the corbel, ensuring the overall stability and ensuring the safety of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

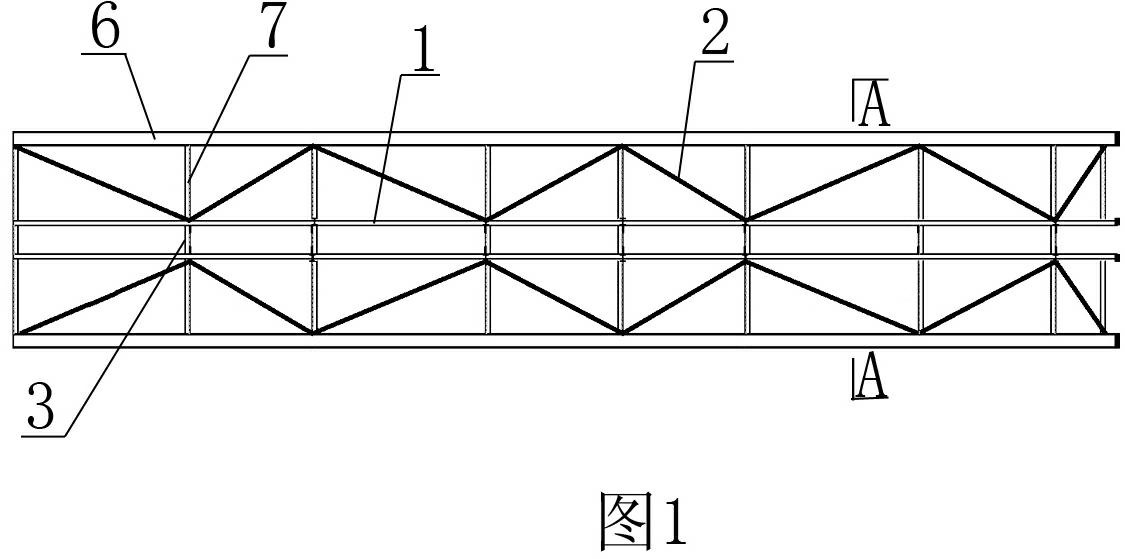

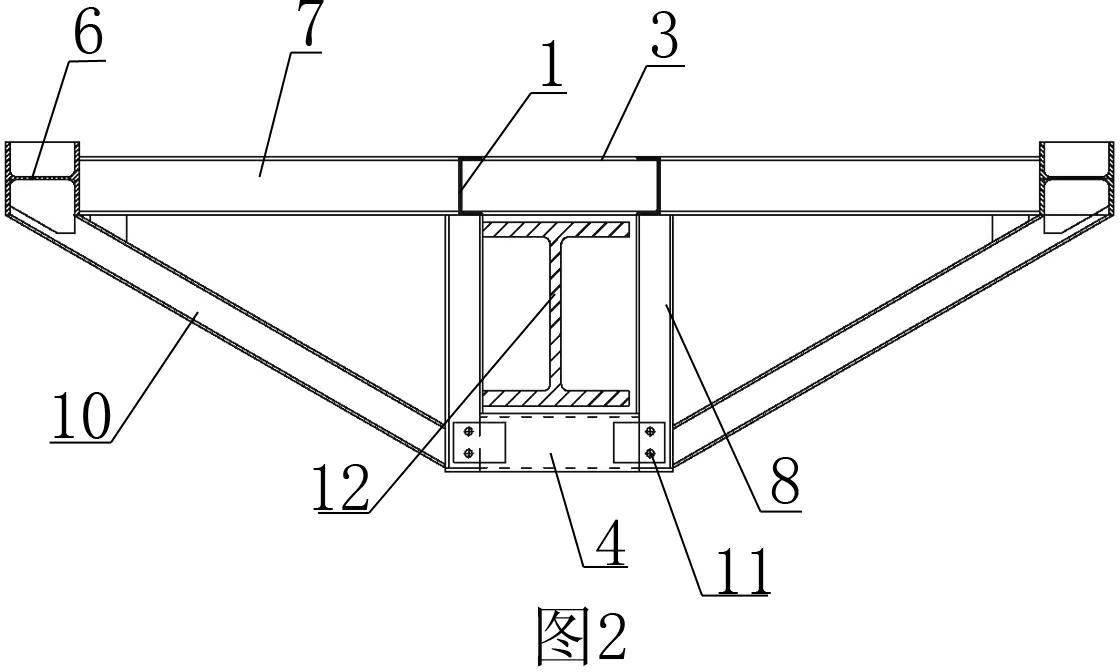

[0048] Examples see Figure 1 to Figure 4 As shown, a lateral reinforcement structure in the overall lifting of a plane steel truss is characterized in that it includes an upper chord reinforcement device and a lower chord reinforcement device, both of which are connected as a whole through an oblique steel pipe 5,

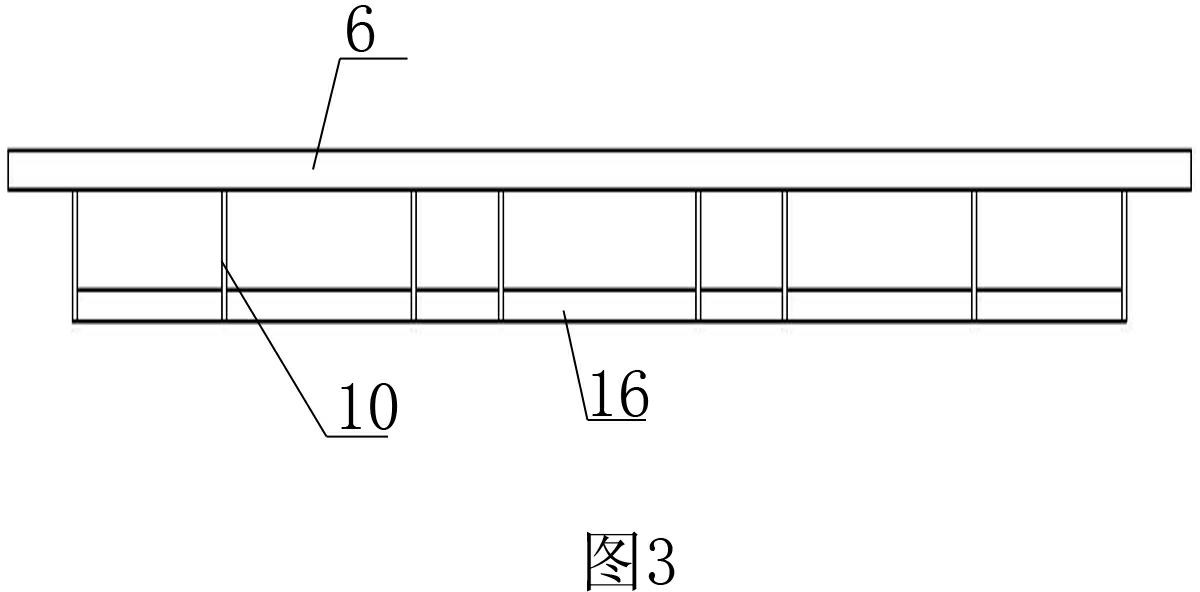

[0049] The upper chord reinforcement device includes two inner beams 1, two outer beams 6, two lower beams 16, upper beam 7, lower beam 4, upper beam 3 and column 8, the inner beam 1 and the external beam 6 are arranged in parallel on the same horizontal plane, and the two are connected by the upper beam 7, and the two internal beams 1 are connected by the upper beam 3, and the lower beam 4 is arranged directly below the upper beam 3 , it is supported by a column 8 with the upper small beam 3, and the adjacent lower beams 4 are connected by two lower beams 16, and the outer ends of the lower beams 4 and the outer beams 6 are connected by braces 10 to form an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com