Detection device for breather pipe of breather valve of oil tank

A detection device and breathing valve technology, applied in the field of tooling and fixtures, can solve the problems of lax incoming quality control, inability to supply oil in the fuel tank, insufficient air pressure in the fuel tank, etc., and achieve the effect of satisfying consistent production, avoiding interference, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

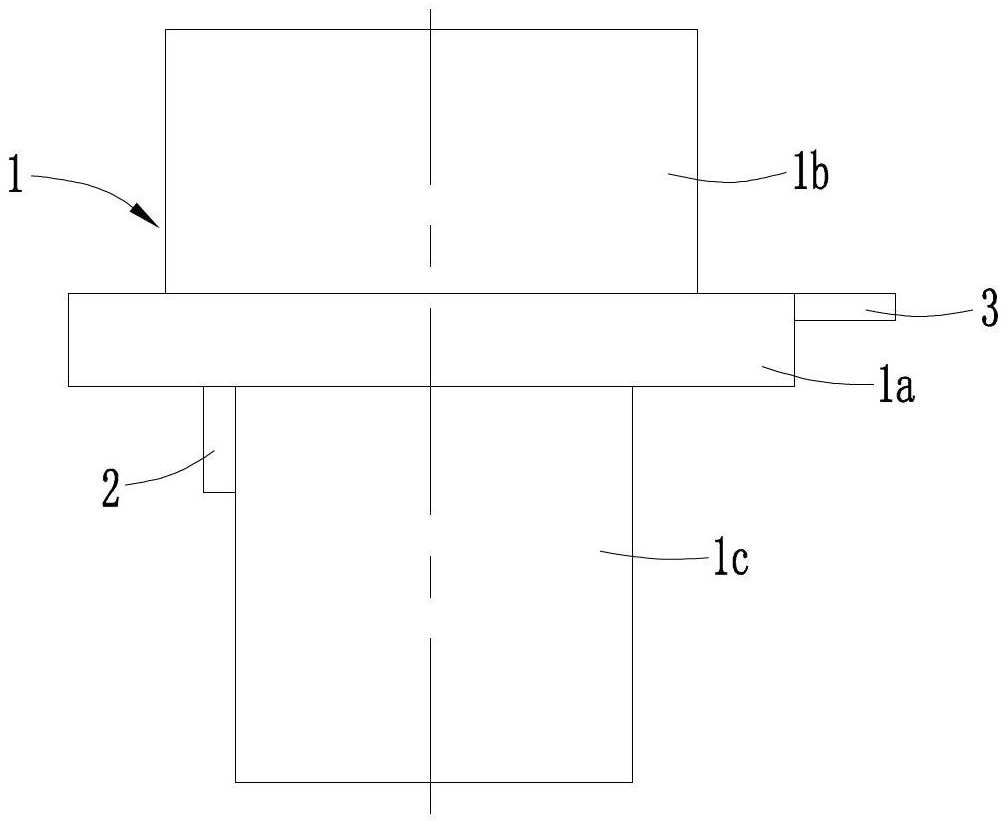

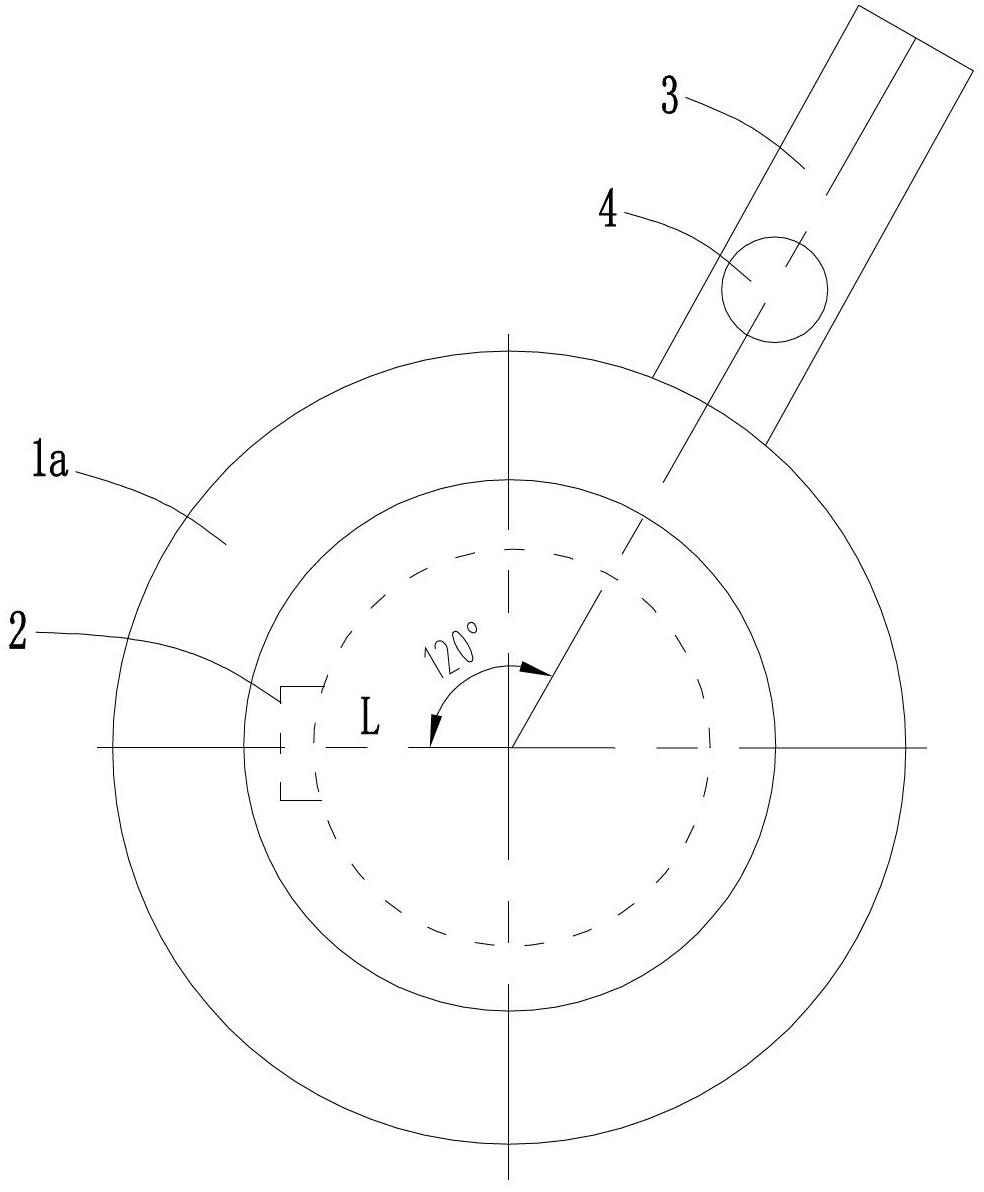

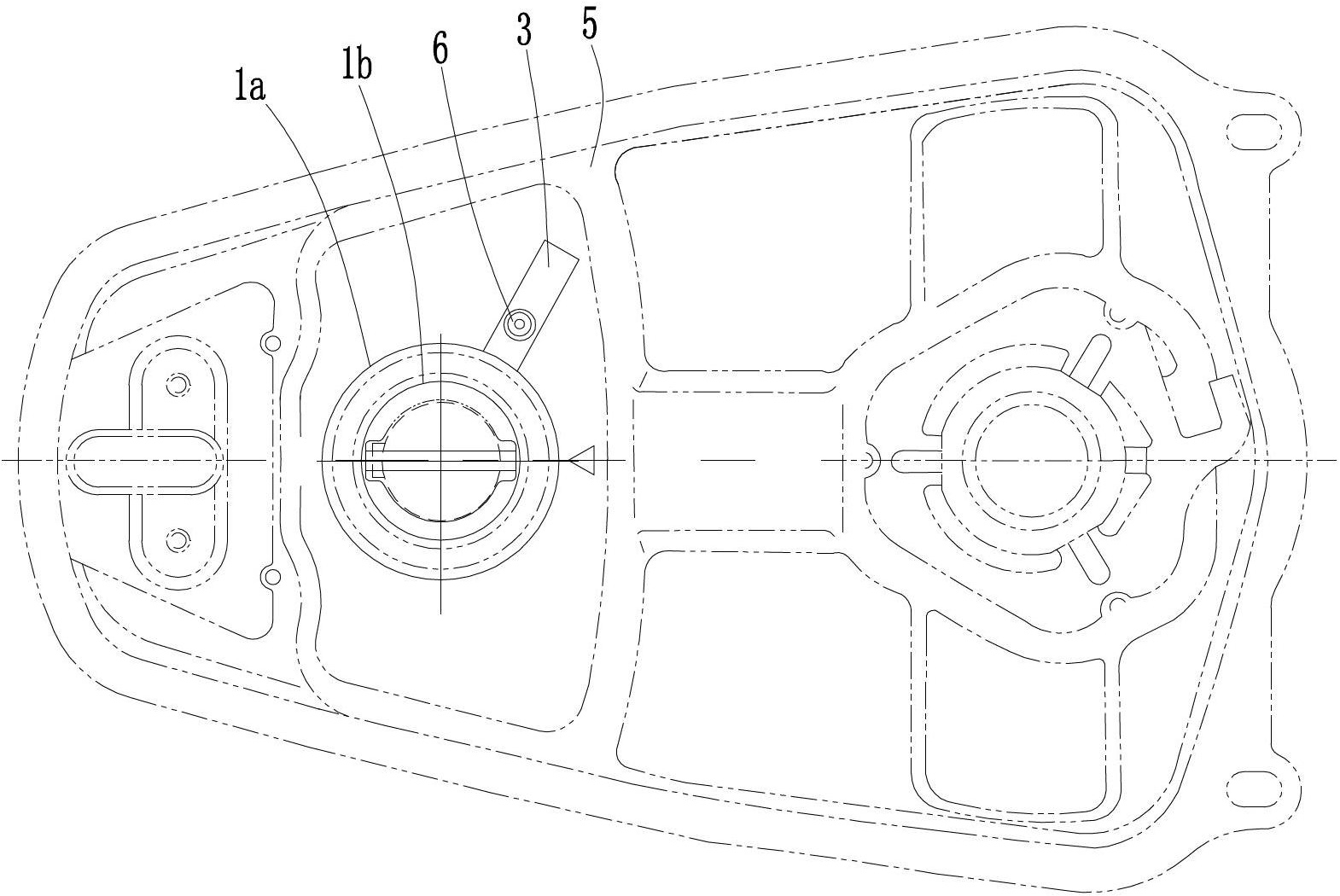

[0014] like figure 1 , figure 2 As shown, the present invention consists of a positioning column 1, a limiting block 2 and a limiting arm 3. Wherein, the positioning column 1 is a cylindrical structure, consisting of an upper column 1b above, a lower column 1c below and an annular boss 1a in the middle, the diameter of the annular boss 1a is the largest, and the diameter of the lower column 1c is the smallest. The upper cylinder 1b, the lower cylinder 1c and the annular boss 1a are integrally structured, and the axis lines of the three are on the same straight line. Be provided with limiter arm 3 beside described annular boss 1a, this limiter arm 3 is elongated rectangular sheet structure, limiter arm 3 and the circumferential surface of annular boss 1a are perpendicular, the root of limiter arm 3 and ring The boss 1a is fixed by welding. A limiting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com