Patents

Literature

93results about How to "Meet the requirements of consistent production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

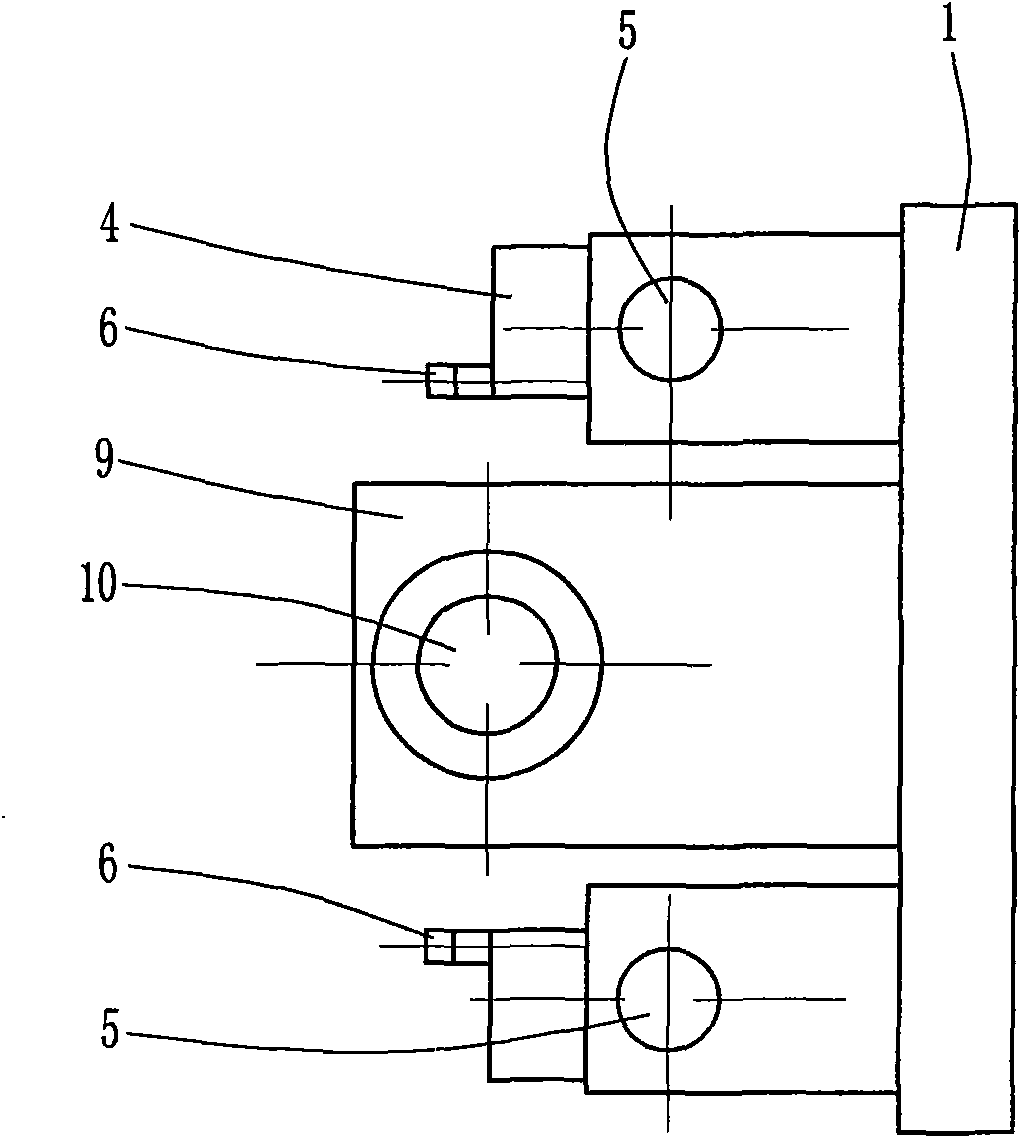

Negative clearance rotation measurement method for third-generation hub bearing unit

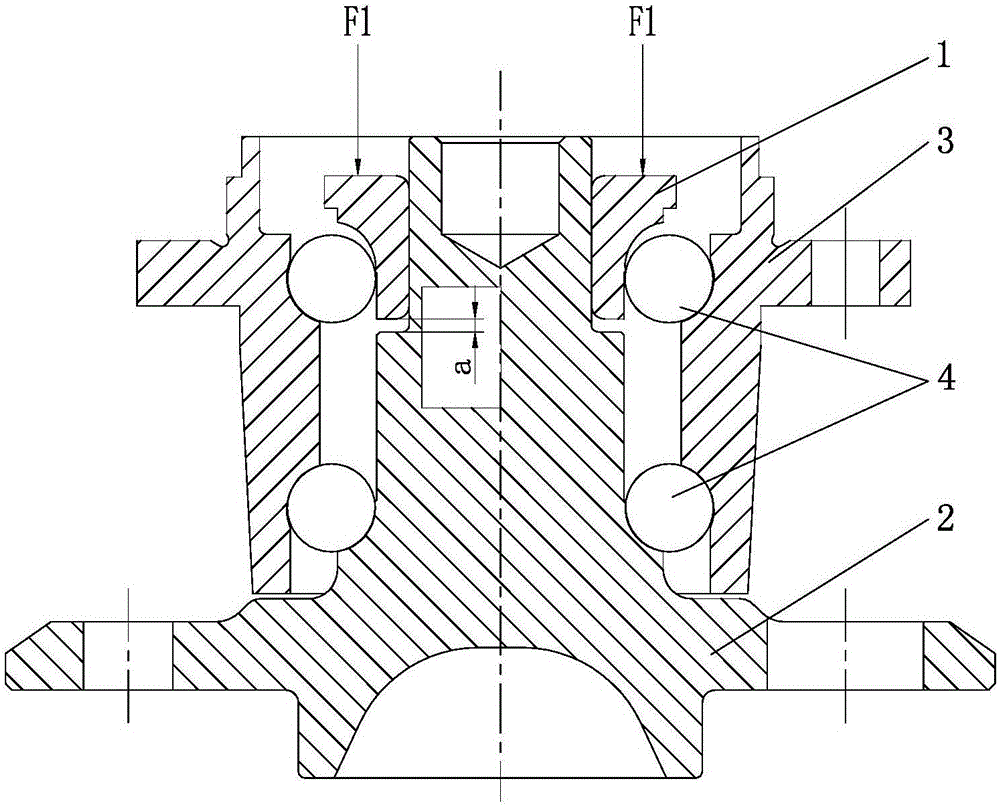

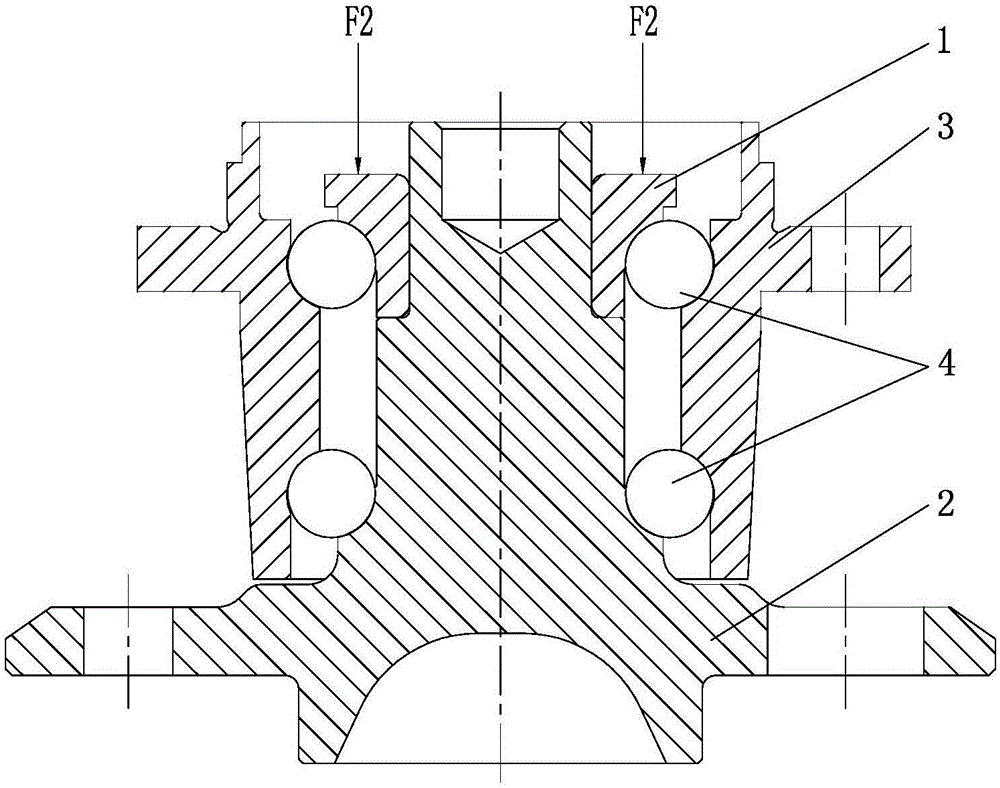

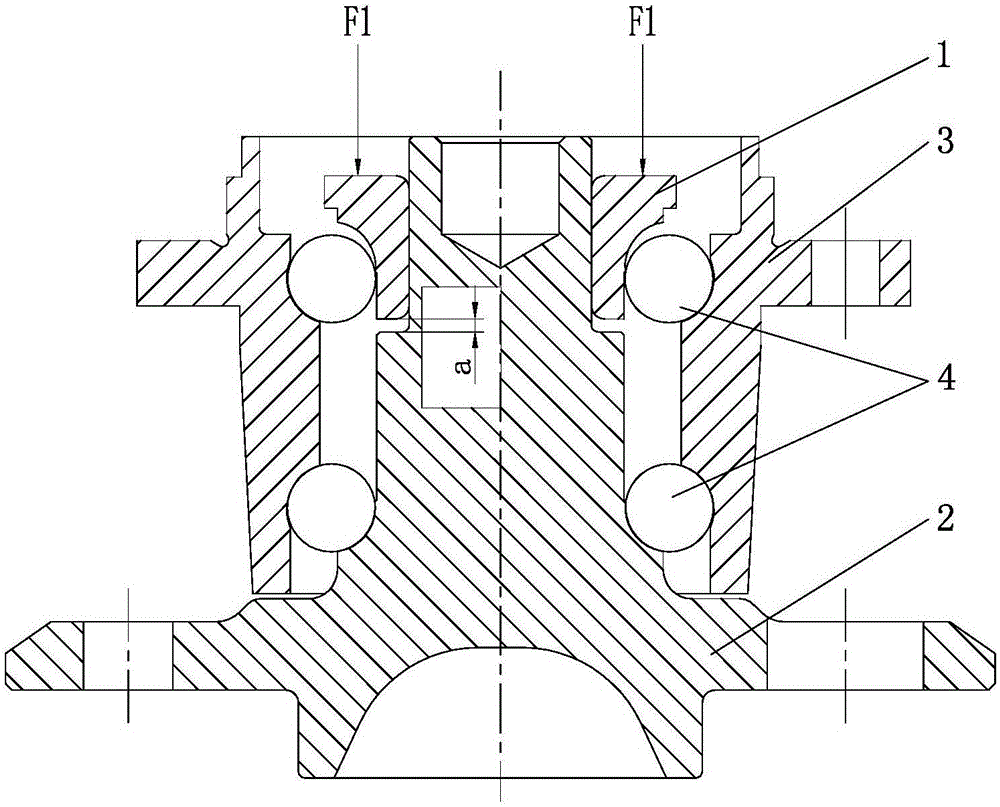

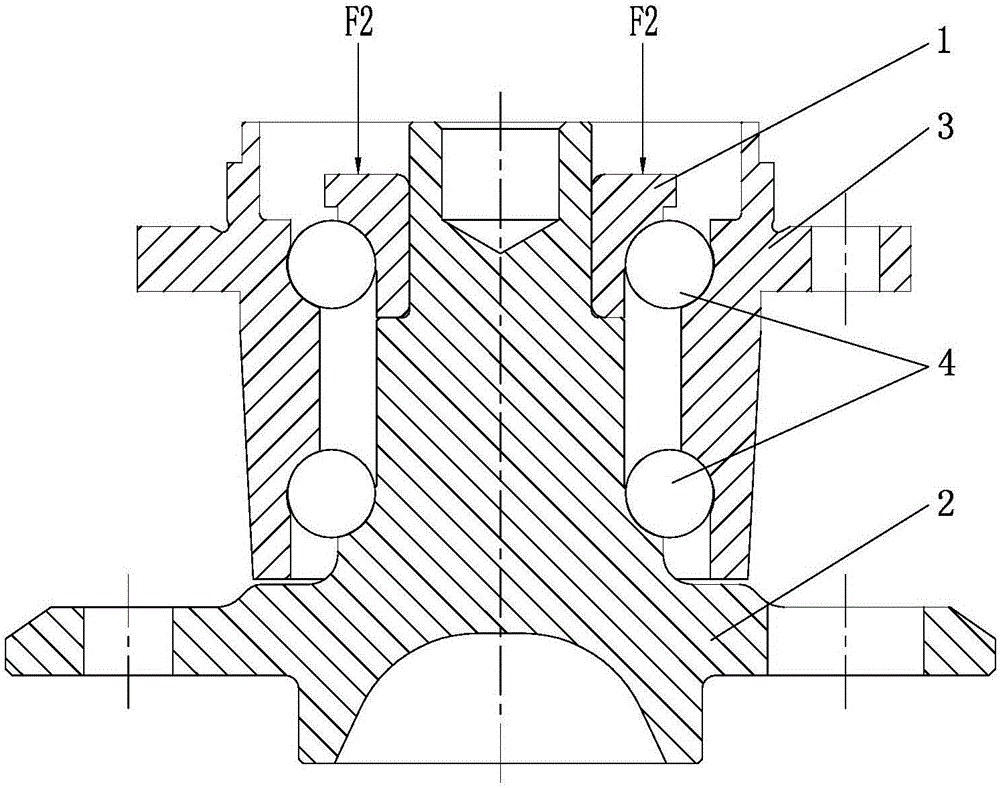

The invention discloses a negative clearance rotation measurement method for a third-generation hub bearing unit. The method includes the following steps that: 1) various components are assembled; 2) a first inner ring is embedded into a shaft on the upper end of a second inner ring, a downward pressing force F1 is applied to the first inner ring so as to carry out pre-pressing, and a distance a is kept between the small end surface of the first inner ring and the shaft shoulder of the second inner ring; 3) the two inner rings are controlled to rotate, and a three-point measurement method is adopted to measure a positive clearance value Ga; 4) a downward pressing force F2 is applied to the first inner ring so as to make the small end surface of the first inner ring contact with the shaft shoulder of the second inner ring; and 5) the displacement L of the first inner ring along an axial direction is measured, and if Ga is smaller than L, a negative clearance value is equal to the result of subtracting L from Ga, if Ga is larger than L, the first inner ring is replaced, and the above 1) to 4) step are repeated. With the negative clearance rotation measurement method of the invention adopted, the negative clearance value of the third-generation hub bearing unit can be directly measured. The negative clearance rotation measurement method has the advantages of simple and convenient operation, high measurement speed, high efficiency and accurate and reliable measurement results, and can ensure product quality in subsequent press and can satisfy a requirement for consistent production.

Owner:CHONGQING CHANGJIANG BEARING

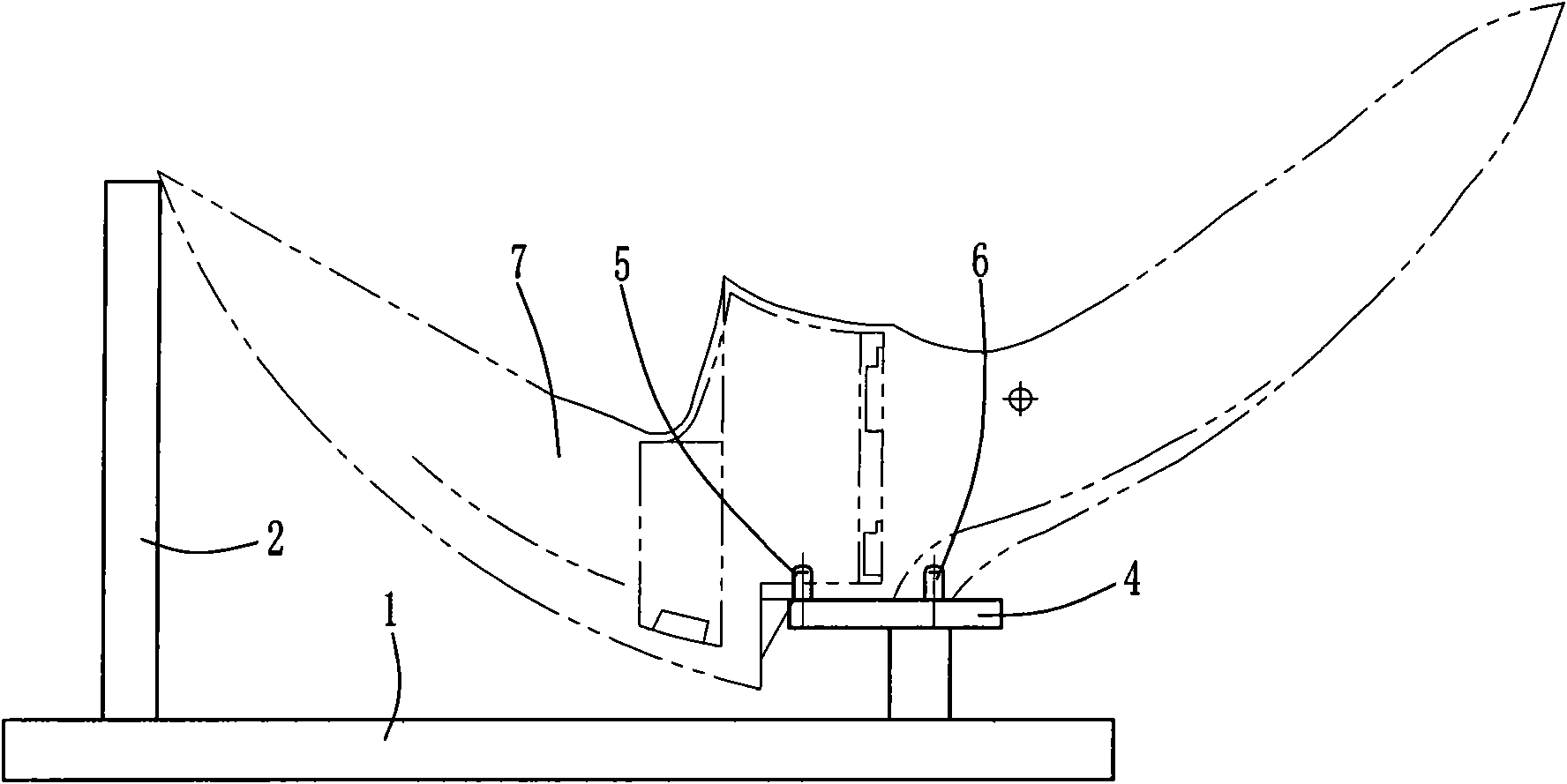

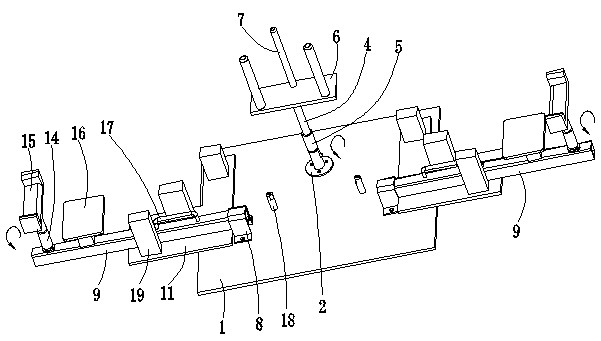

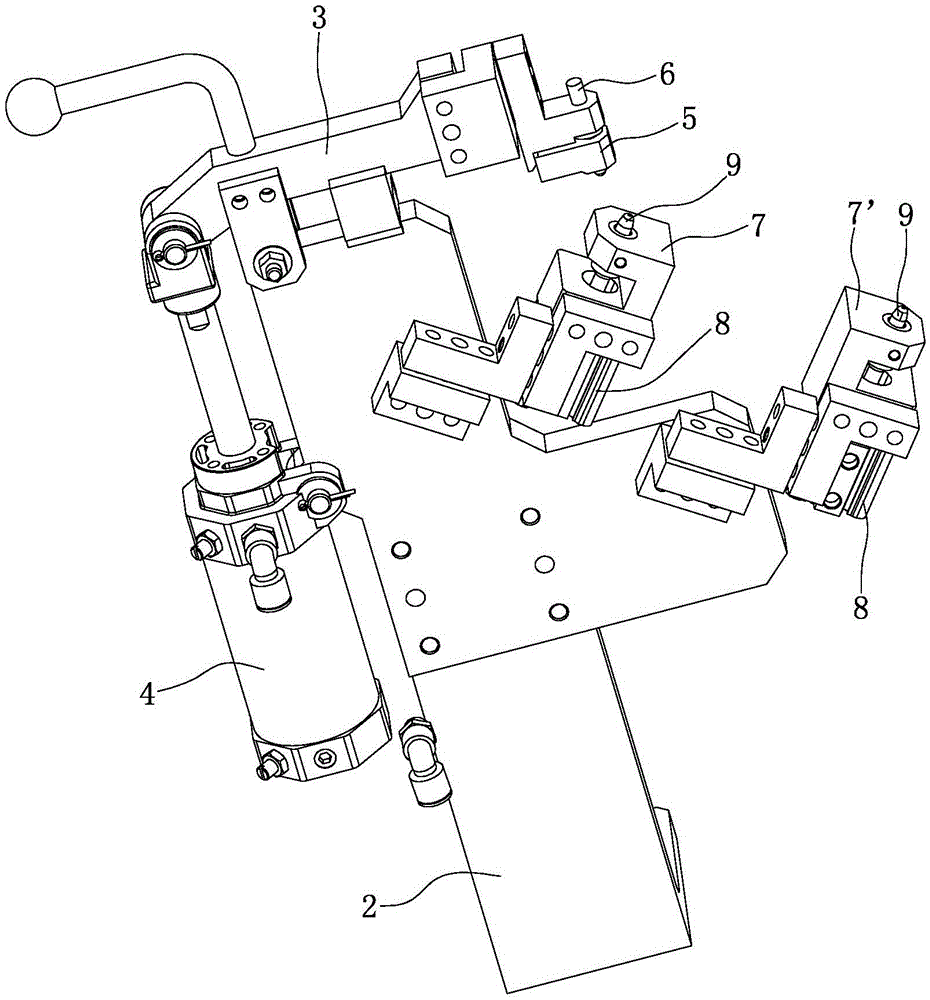

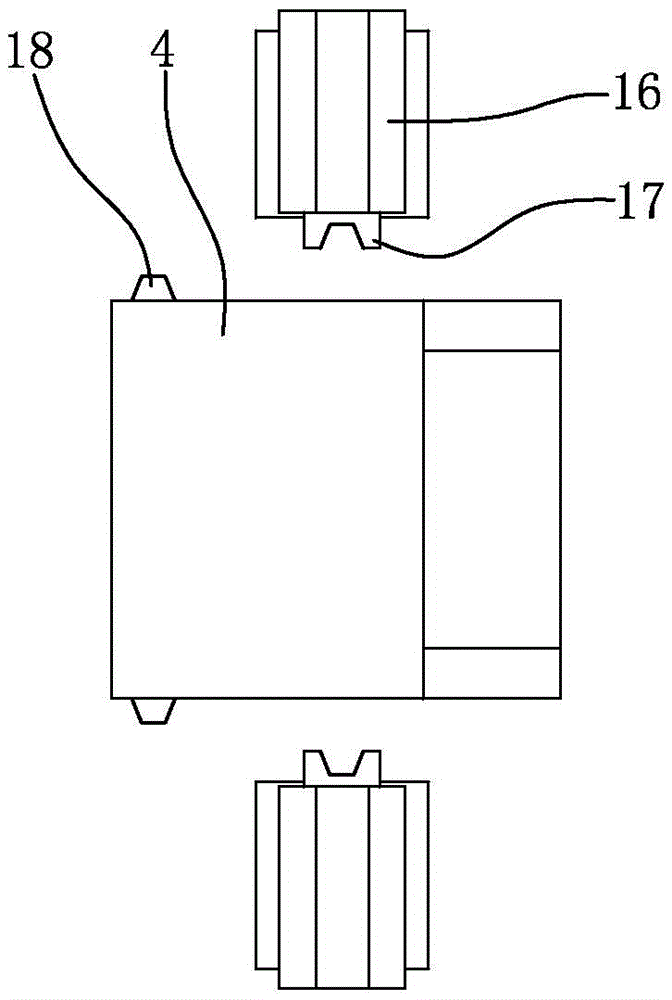

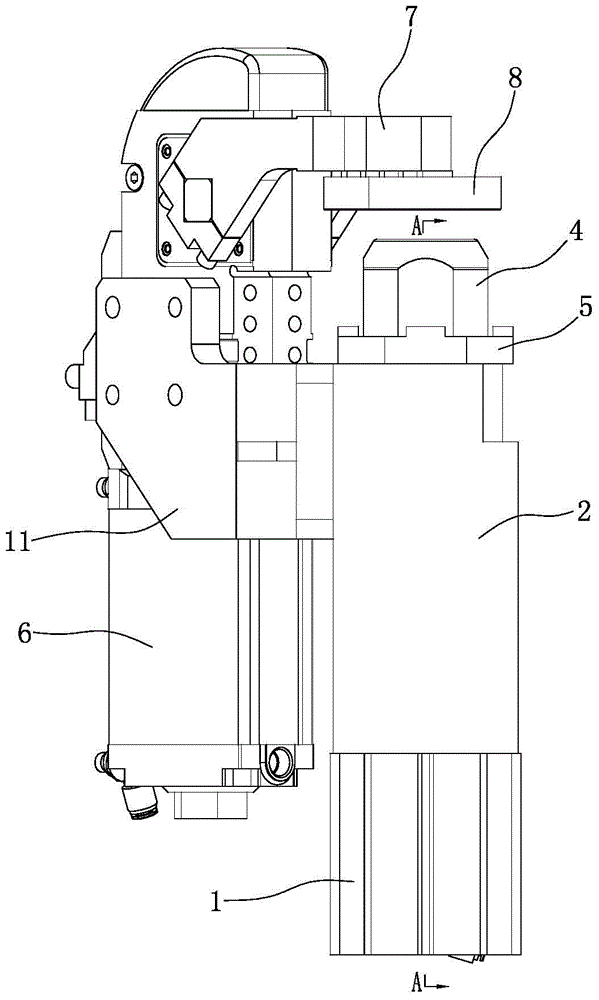

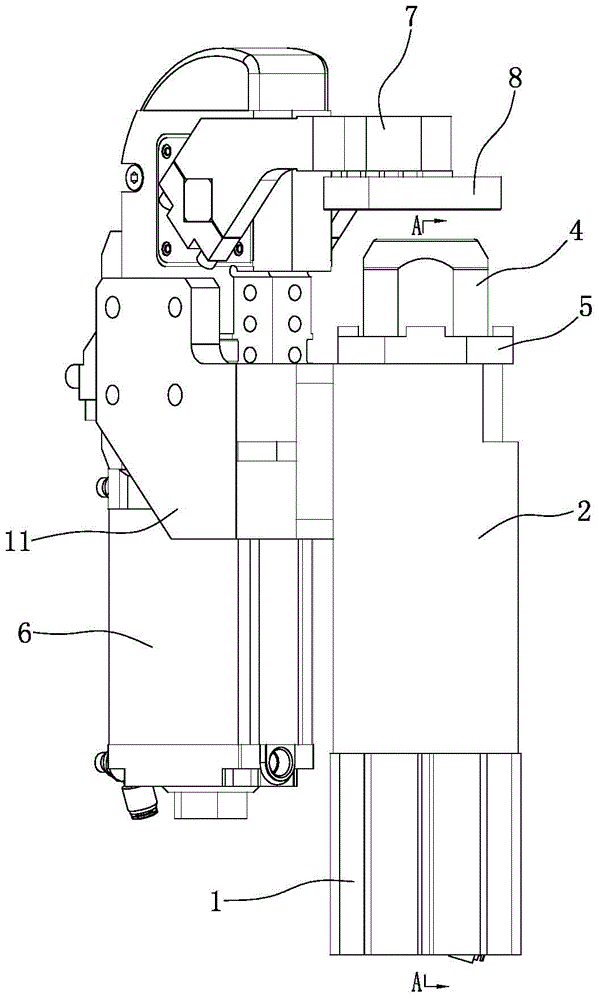

Front and back clamping mechanism for welding mounting bracket assembly of automobile steering column

InactiveCN104551495ASame structureIncrease contact areaWelding/cutting auxillary devicesAuxillary welding devicesSteering columnCushion

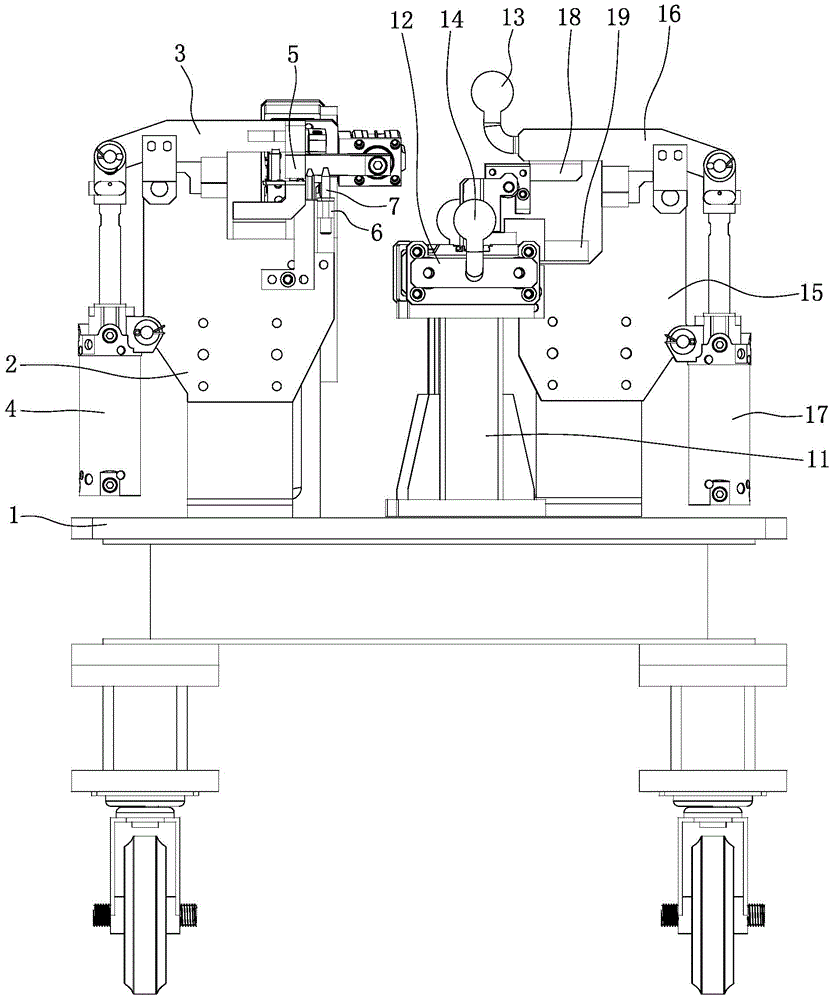

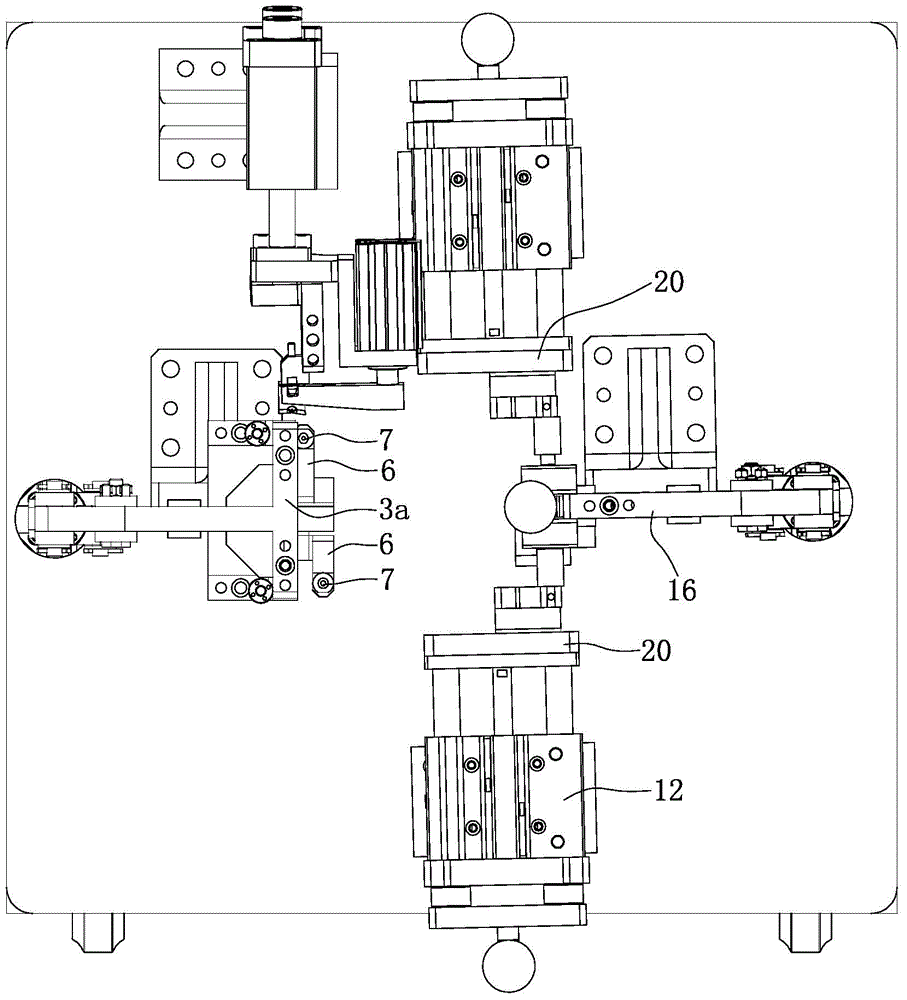

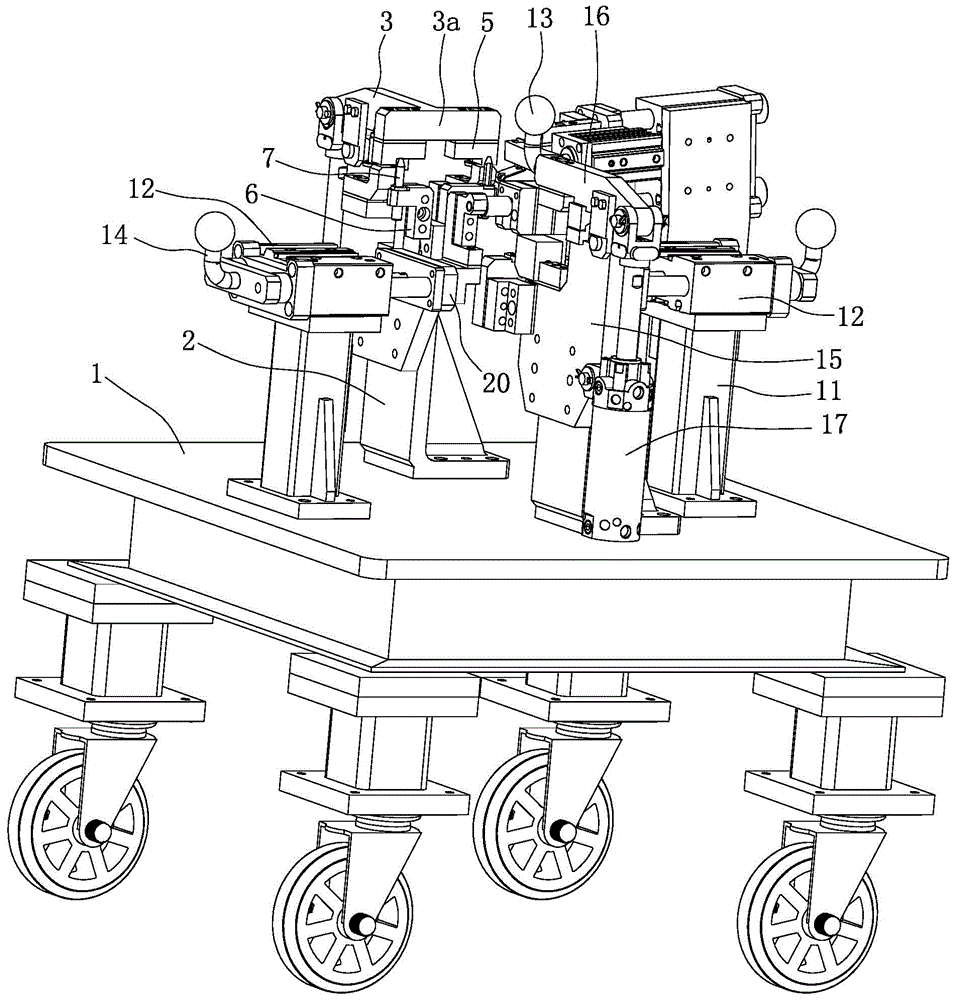

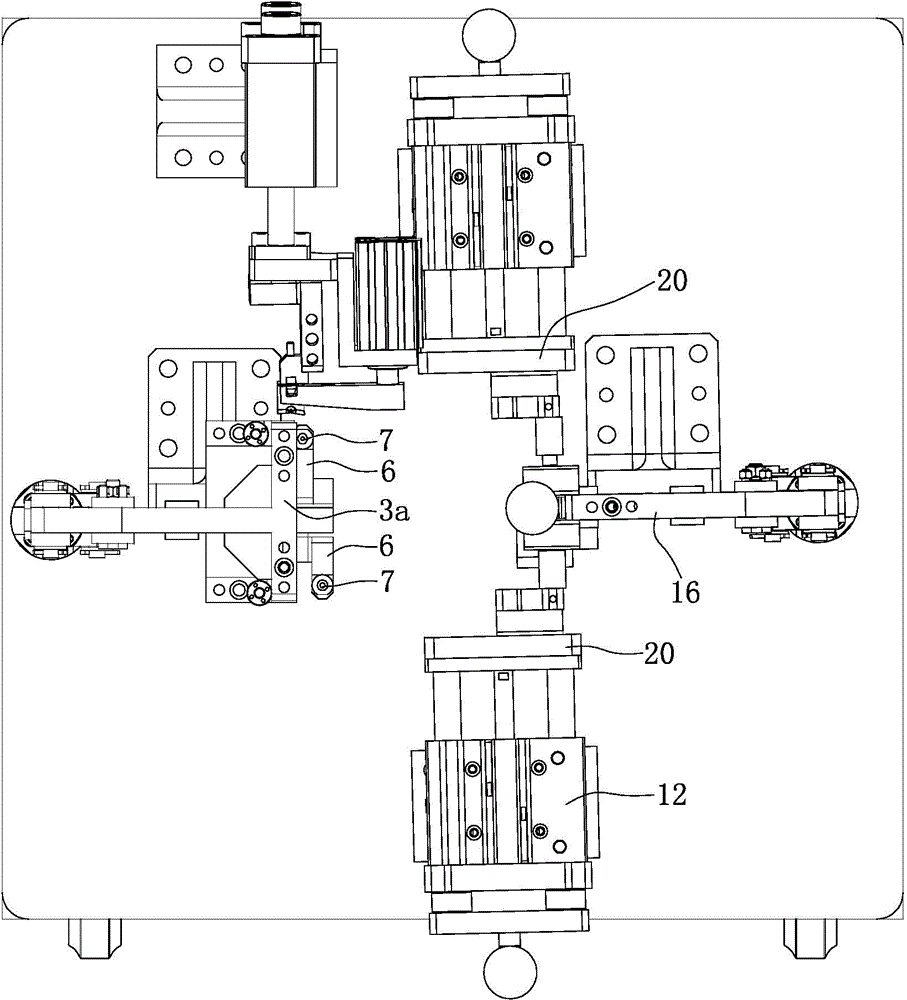

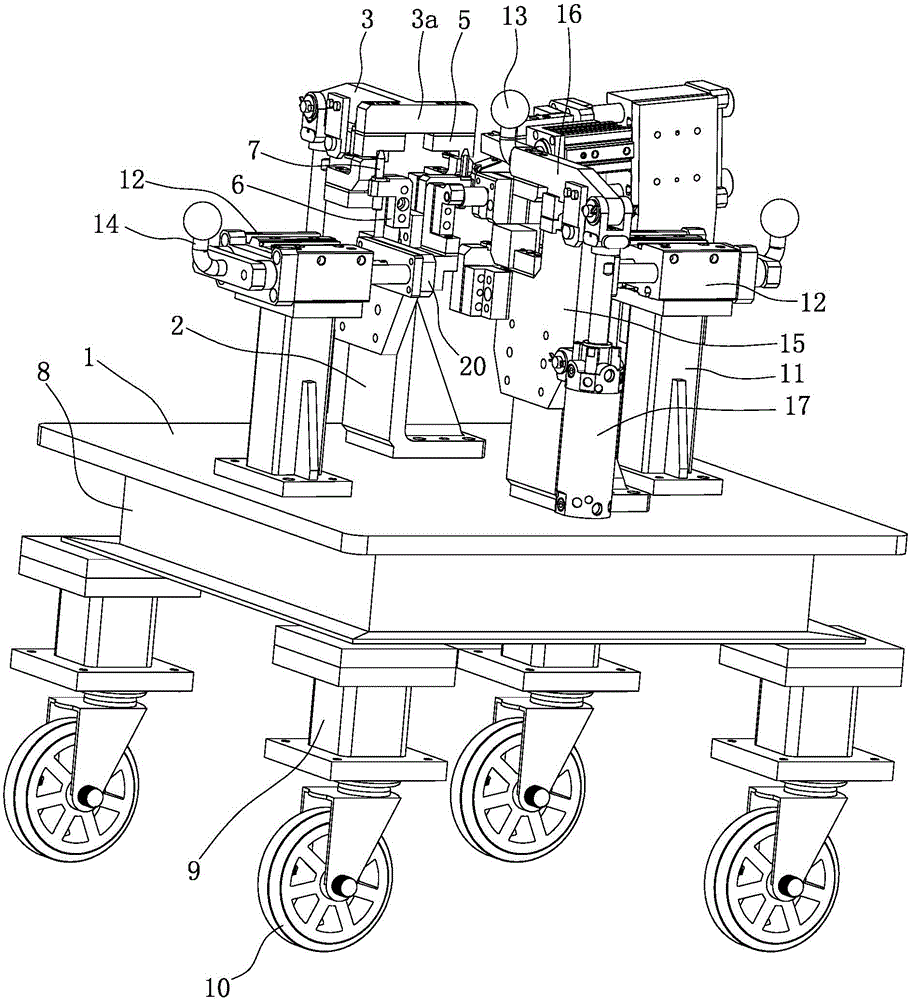

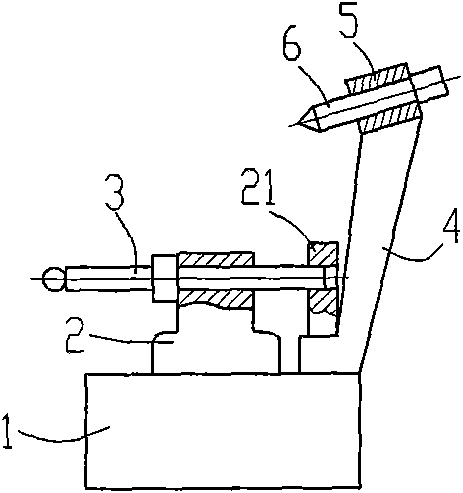

The invention discloses a front and back clamping mechanism for welding a mounting bracket assembly of an automobile steering column. A head support (2) is arranged on the front end of an upper surface of a bottom plate (1), the top of the head support (2) is hinged to a front oscillating arm (3), a cross bar (3a) is integrally formed on the rear end of the front oscillating arm (3), front pressure blocks (5) are symmetrically arranged on the left end and the right end of the bottom of the cross bar (3a), and a left and right positioning block (6) is arranged below the cross bar (3a); a tail support (15) is arranged on the rear end of the upper surface of the bottom plate (1), the top of the tail support (15) is hinged to a rear oscillating arm (16), a rear pressure block (18) is arranged at the bottom of the front end of the rear oscillating arm (16), and a cushion block (19) is arranged below the rear pressure block (18). The welding of the mounting bracket assembly of the automobile steering column can be completed by adopting a set of clamp, on one hand, the positioning is reliable to meet the production consistency requirement; on the other hand, the procedures can be effectively reduced, the operation is simple and fast, and the welding efficiency can be greatly improved.

Owner:CHONGQING DADONG AUTO PARTS

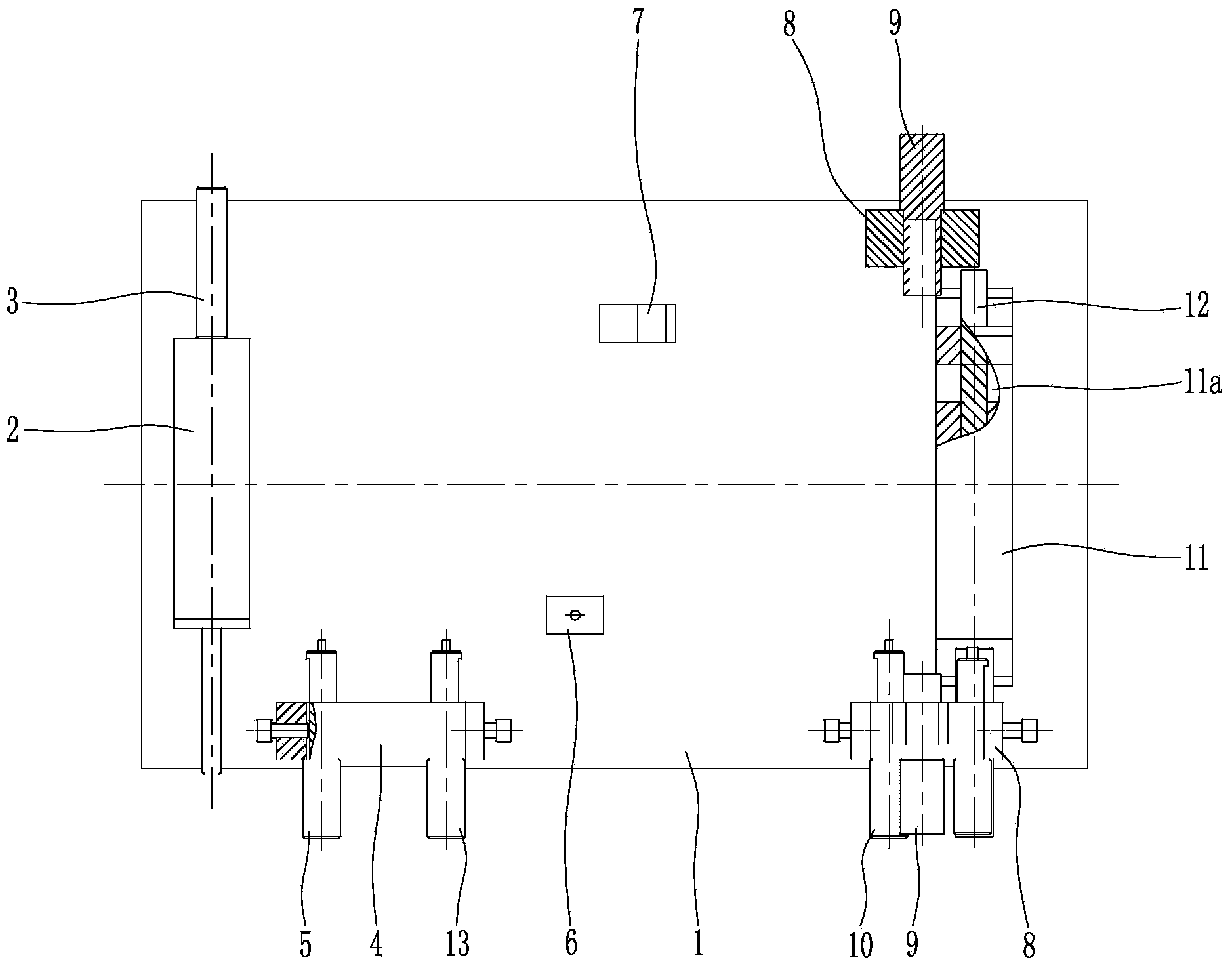

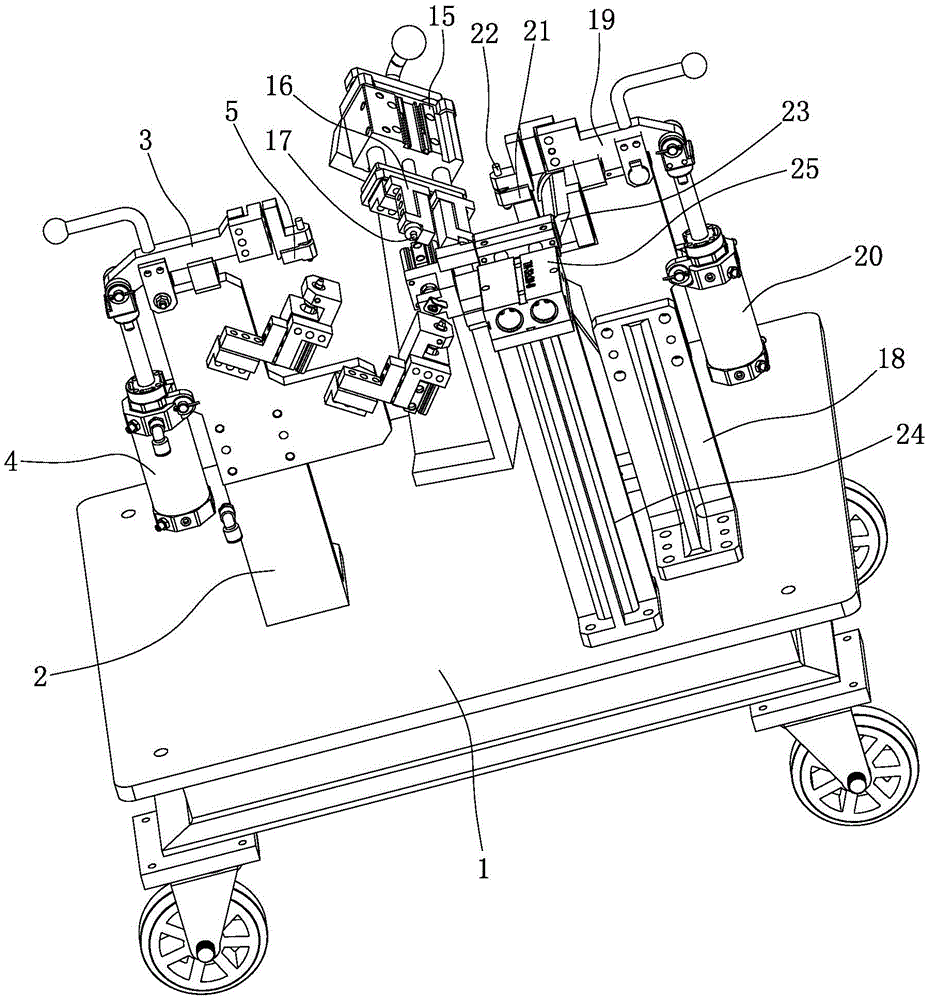

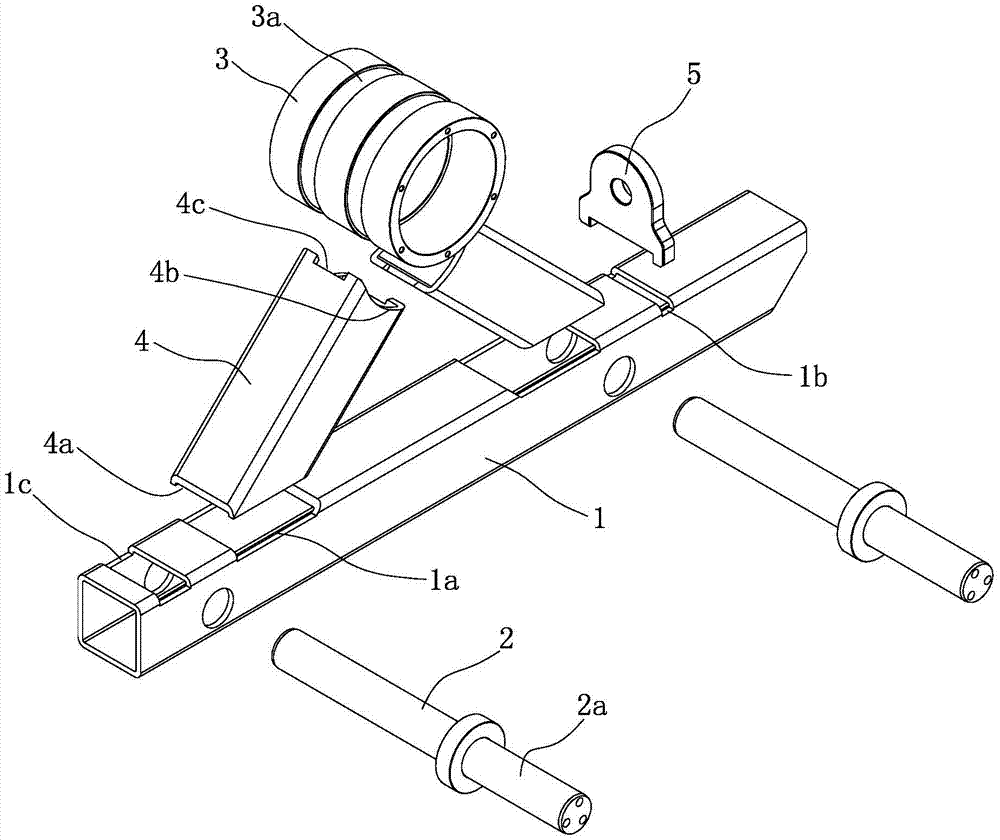

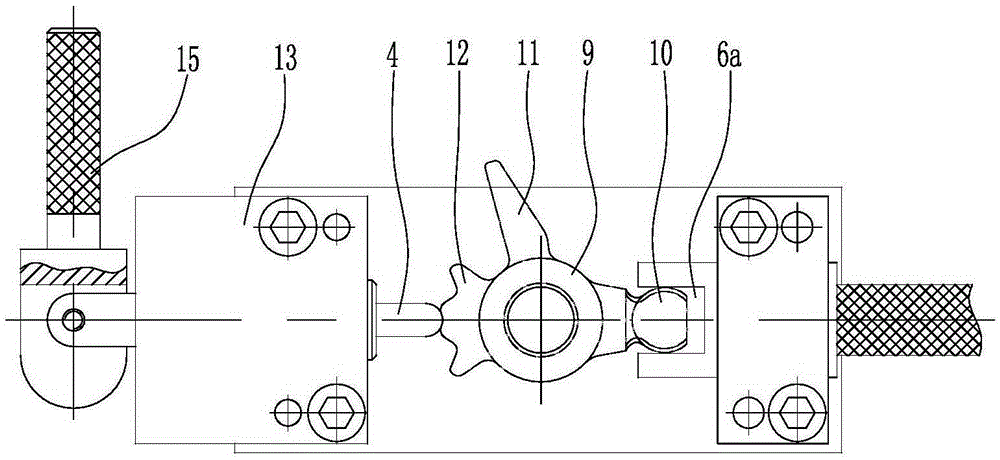

Clamp for welding automobile steering support reinforcing support assembly

InactiveCN104526225AGuaranteed accuracyPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

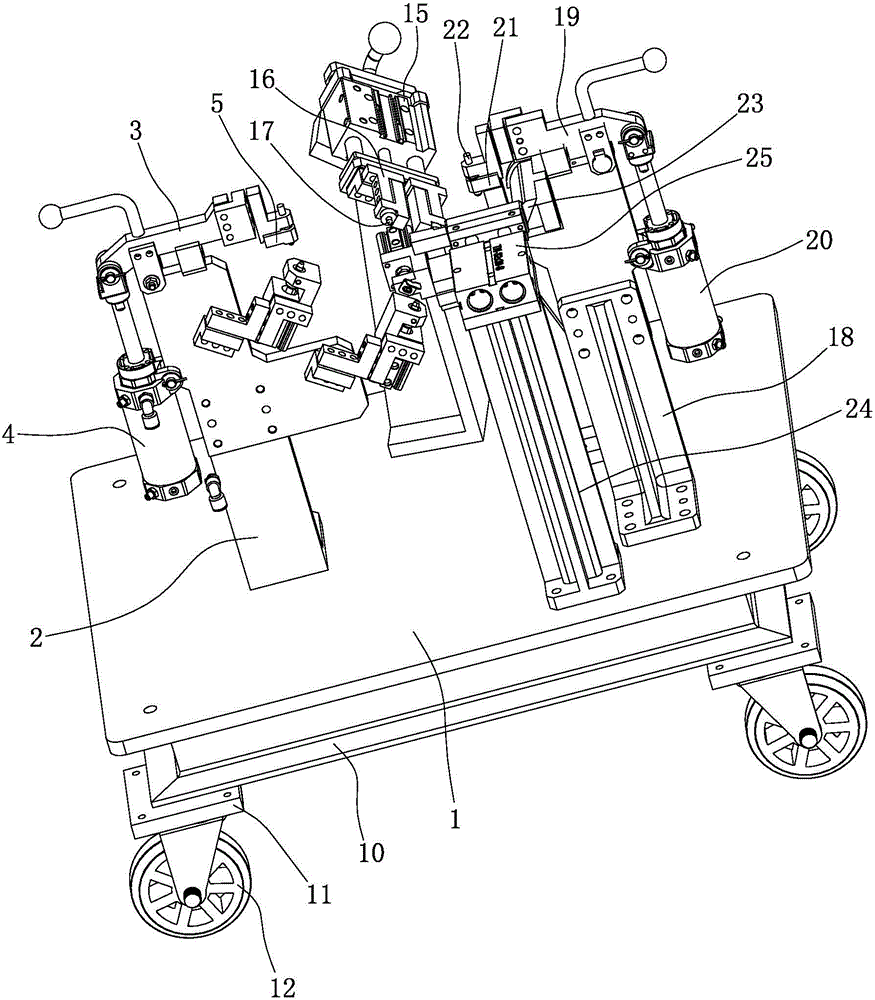

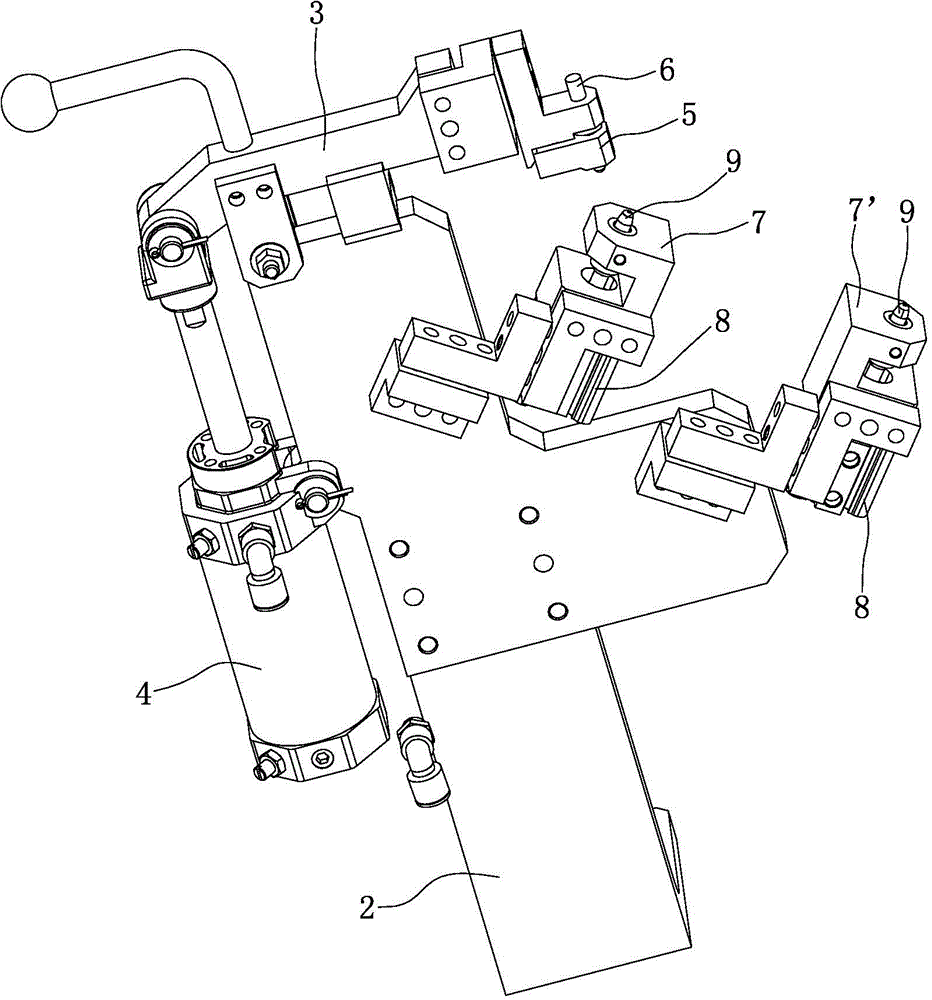

The invention discloses a clamp for welding an automobile steering support reinforcing support assembly. A head support (2) is arranged at the front end of an upper plate face of a base plate (1), a front swing arm (3) is hinged to the top of the head support (2), a front press block (5) is installed at the rear end of the front swing arm (3), a tail support (18) is arranged at the rear end of the upper plate face of the base plate (1), the top of the tail support (18) is hinged to a rear swing arm (19), and a rear press block (21) is arranged at the bottom of the front end of the rear swing arm (19). The base plate (1) is supported by a base frame (10), rectangular small platforms (11) are arranged at the four corners of the bottom of the base frame (10), and rollers (12) are installed below the small platforms (11). The clamp is ingenious in design, simple and compact in structure, reasonable in arrangement, easy to assemble and reliable in location. An upper reinforcing frame, a lower reinforcing frame and a cable support are fixed in the welding process through the clamp, welding quality is ensured, and requirements for consistent production are met.

Owner:CHONGQING DADONG AUTO PARTS

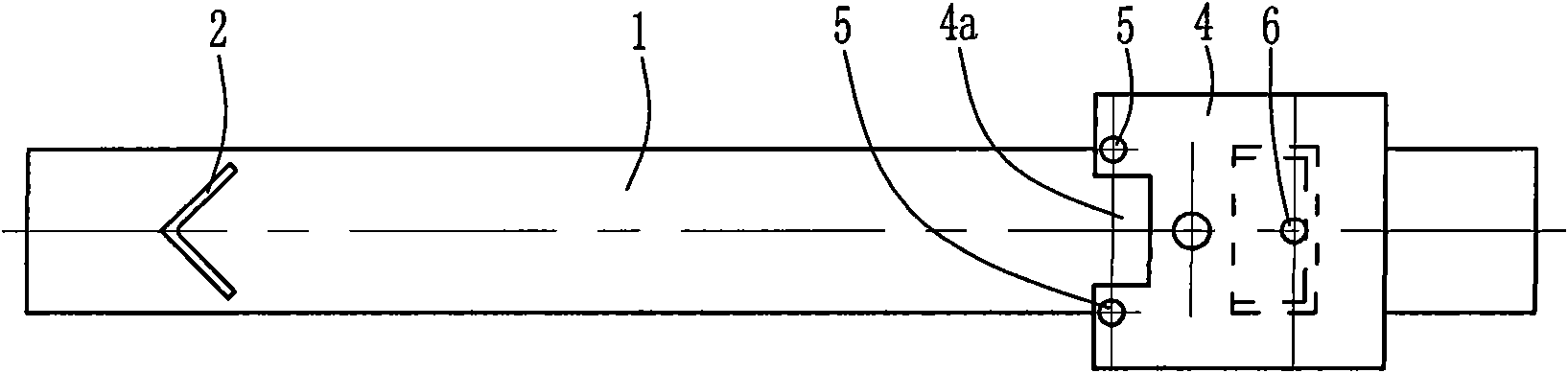

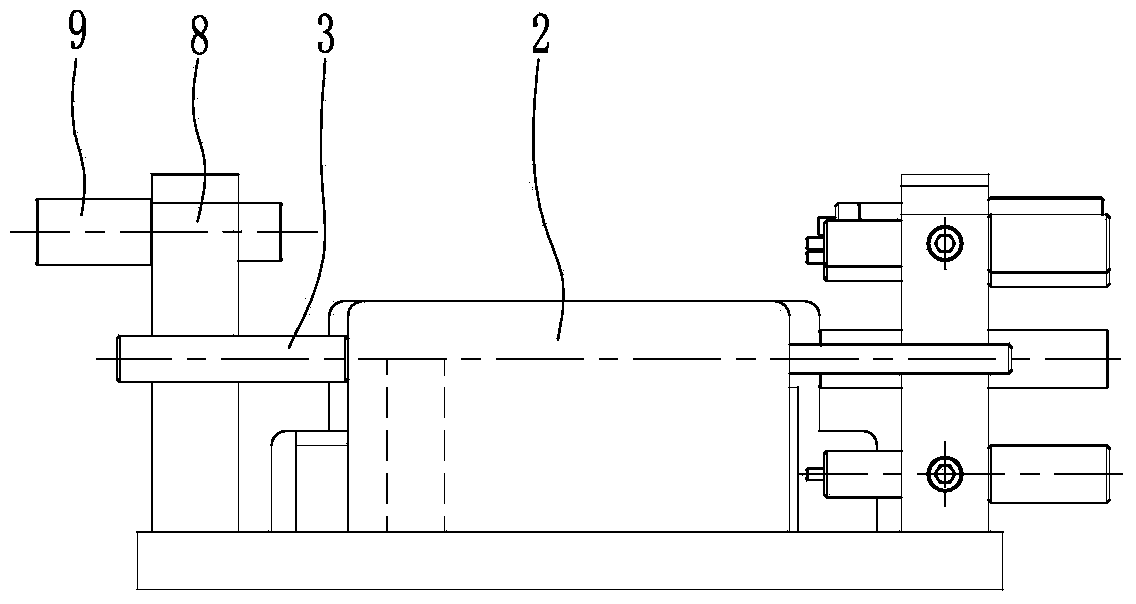

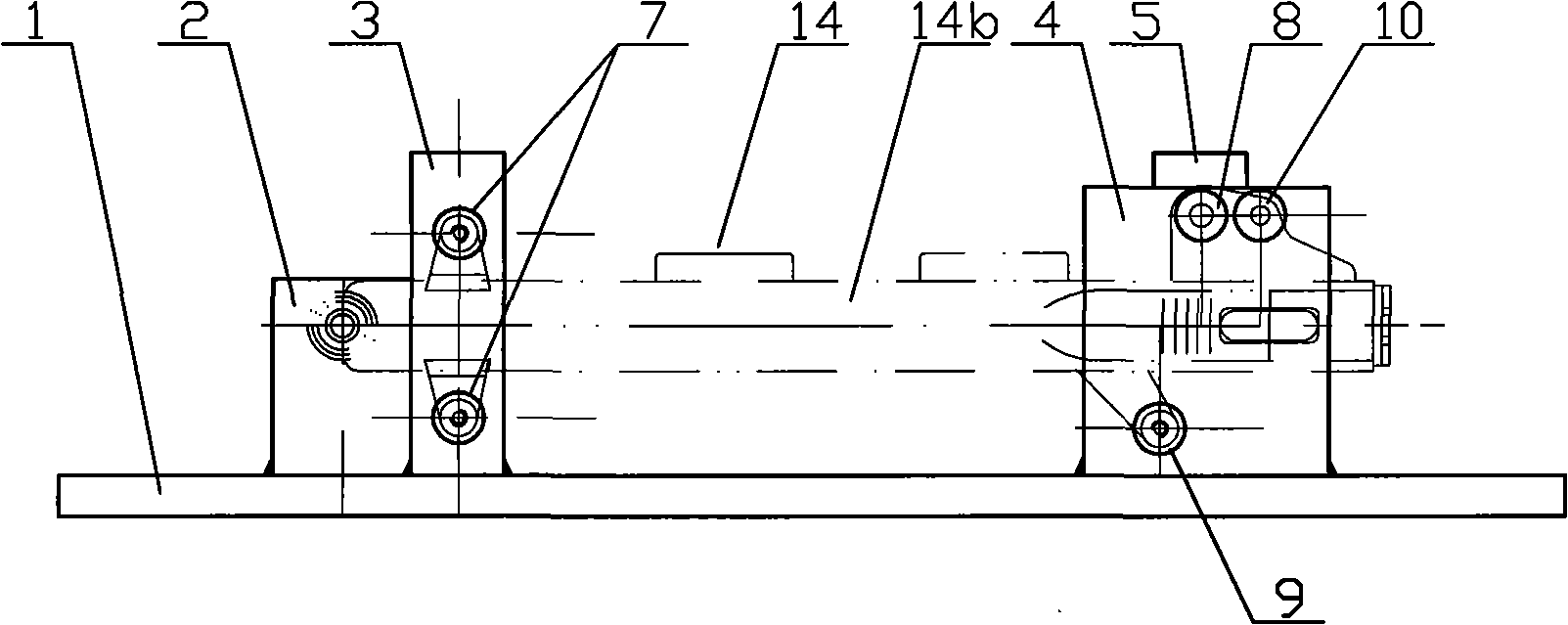

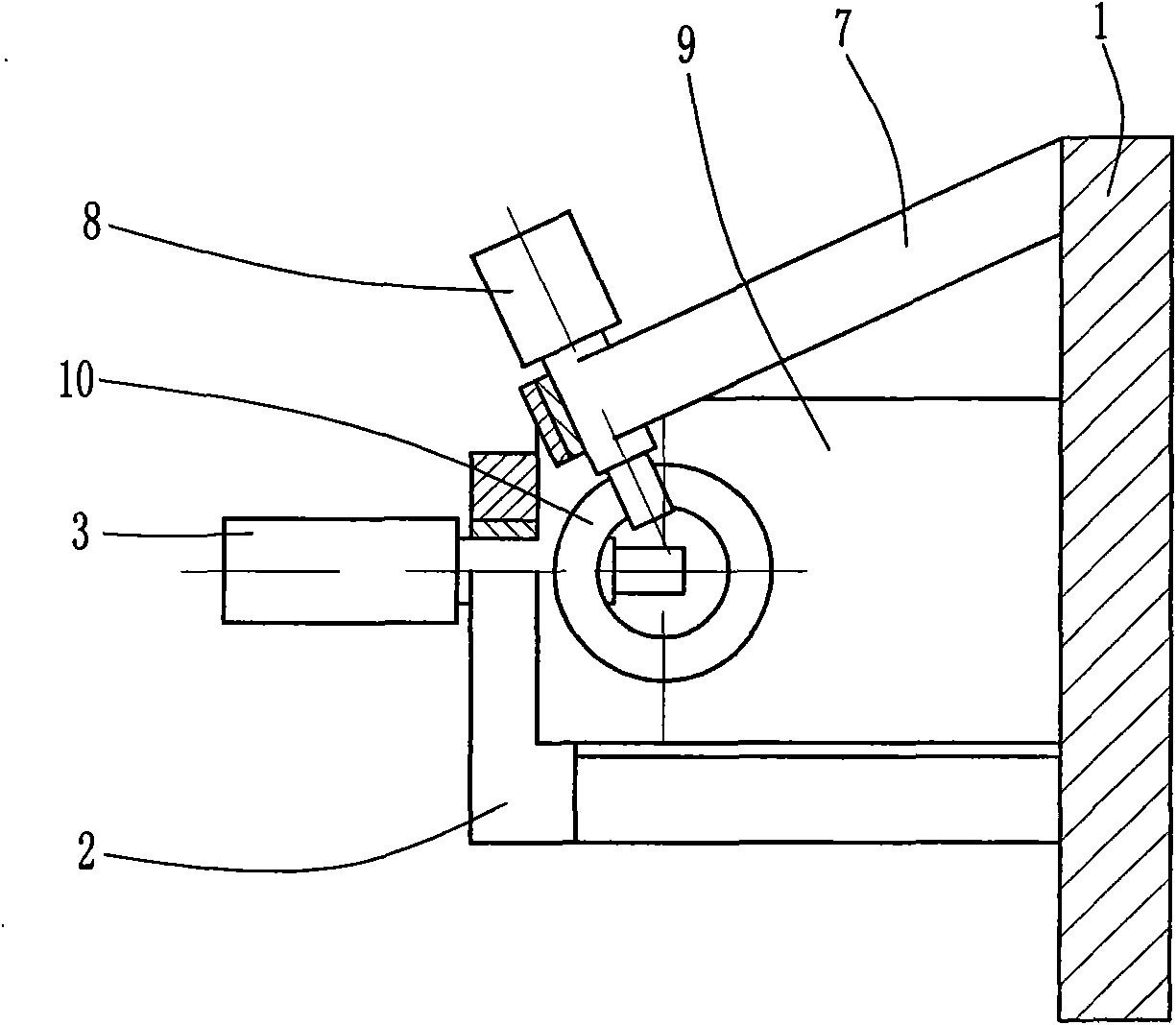

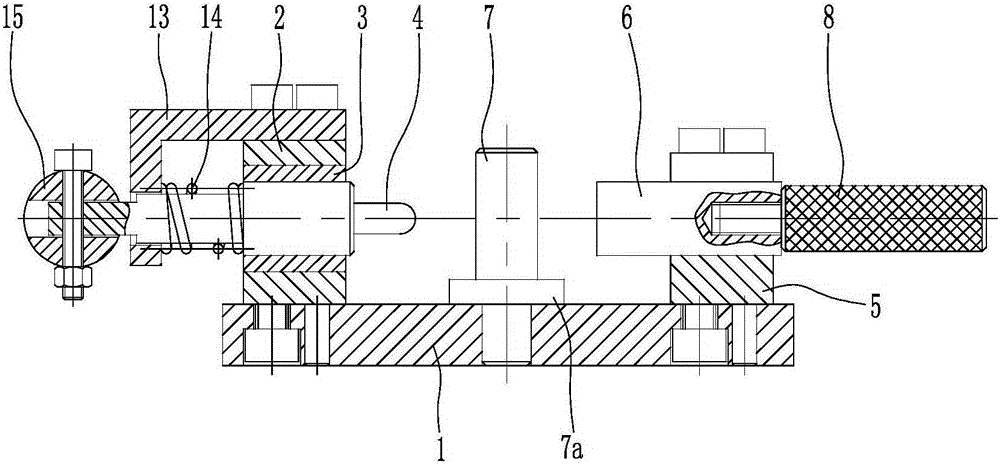

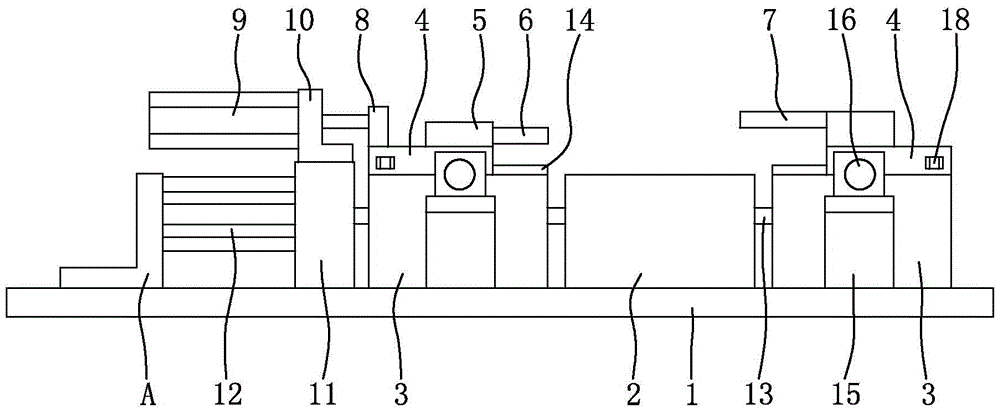

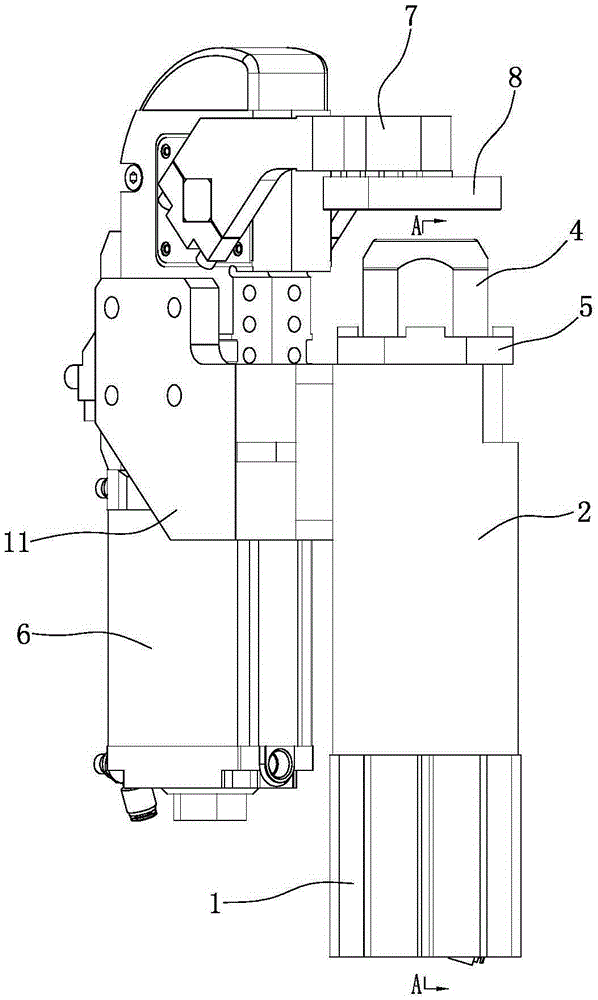

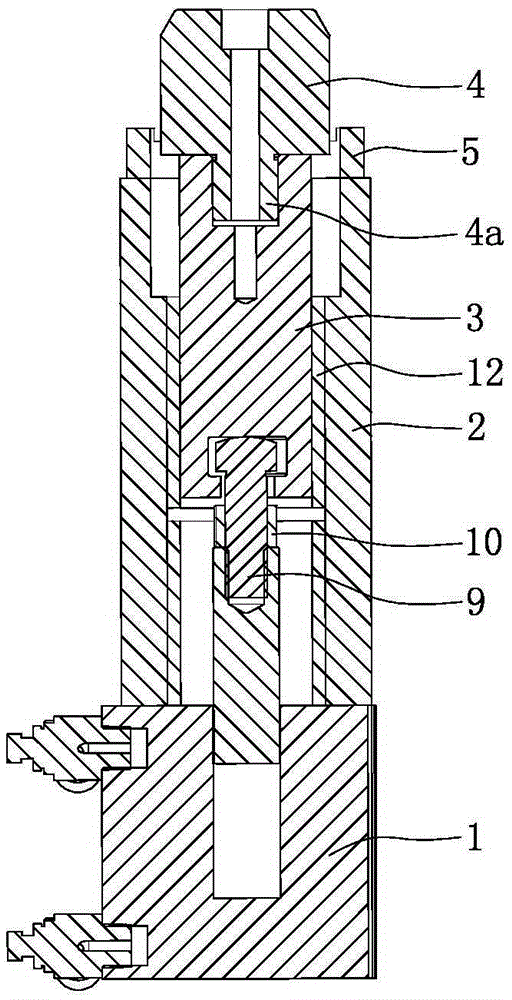

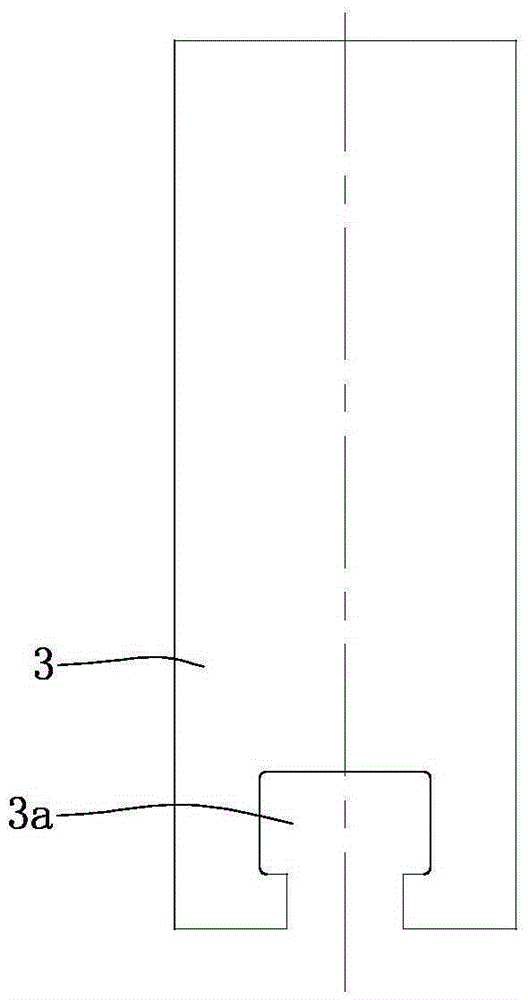

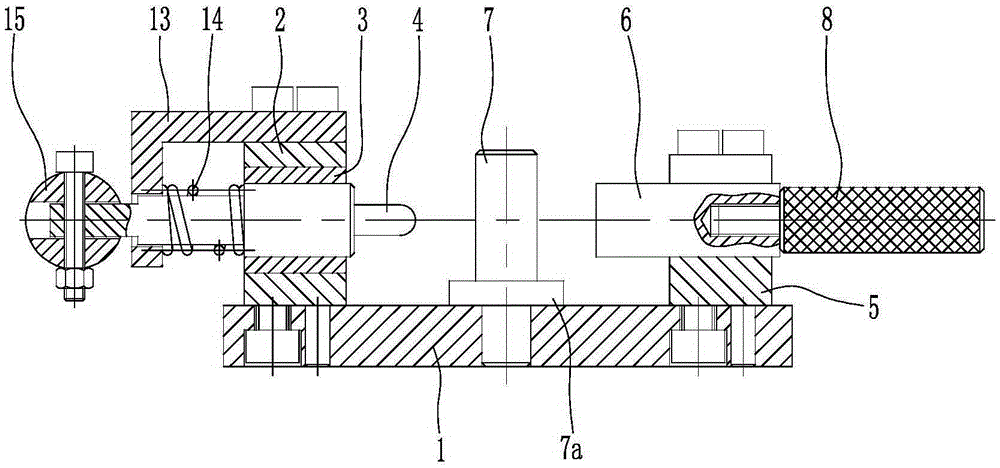

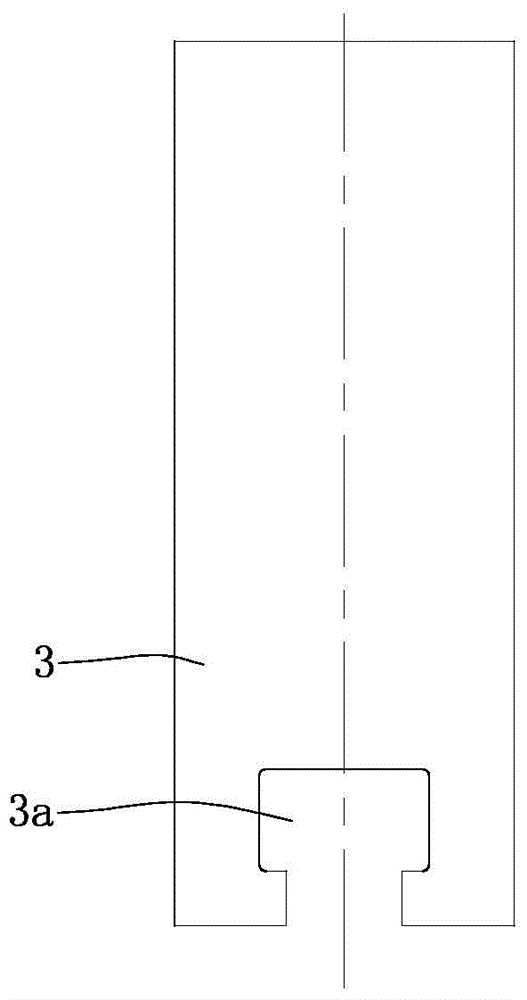

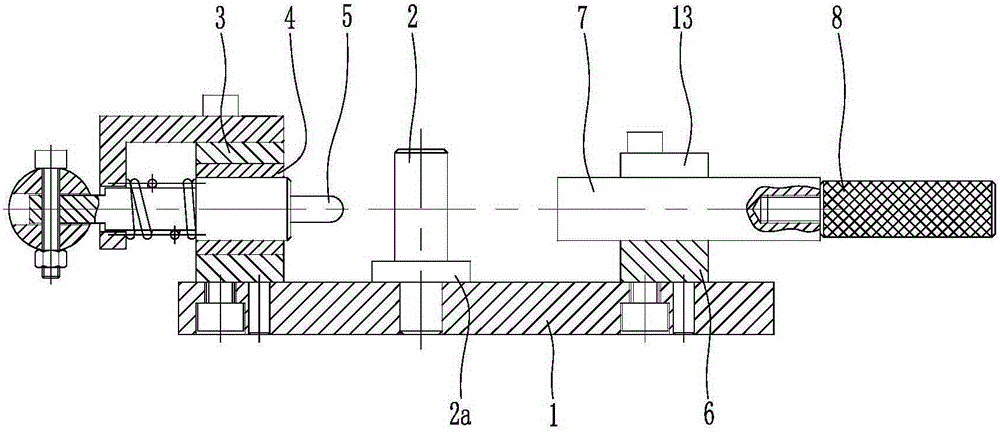

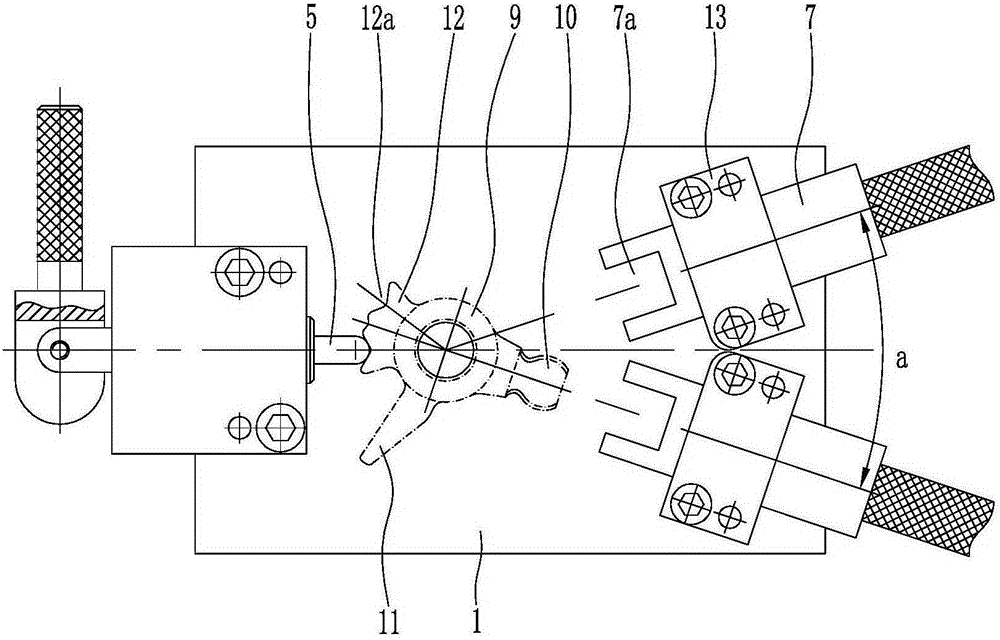

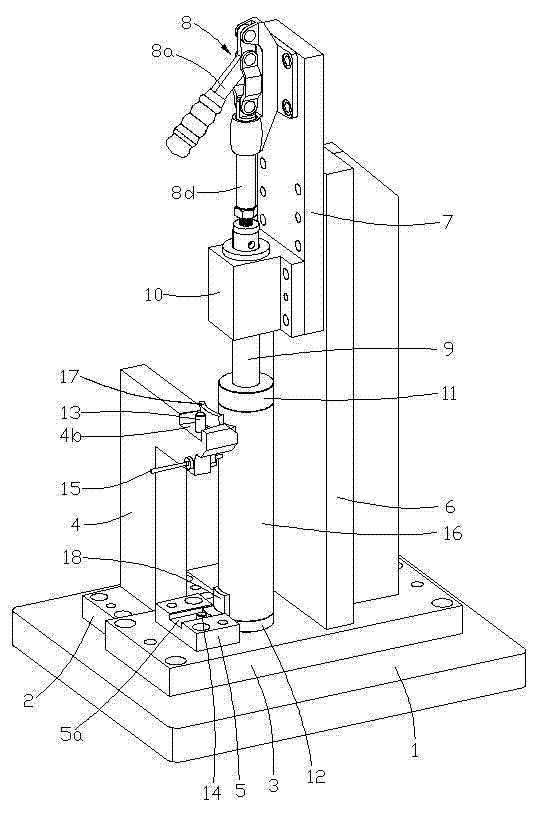

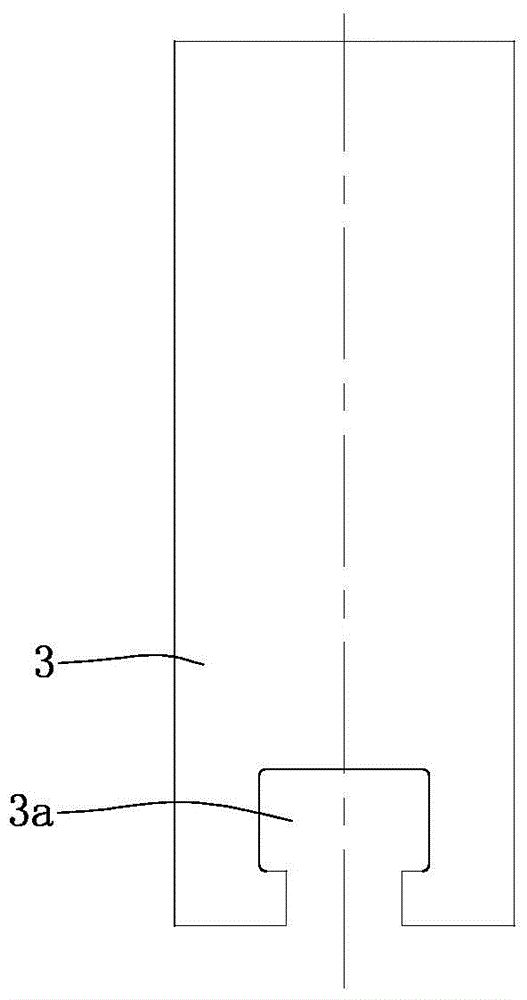

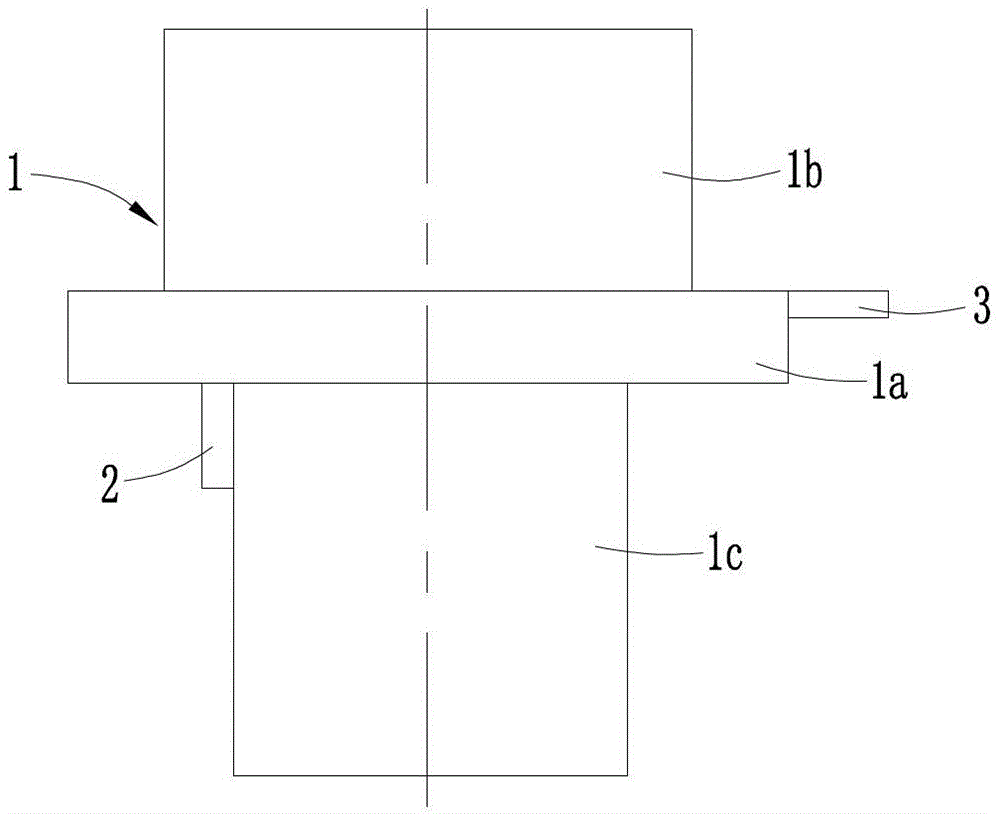

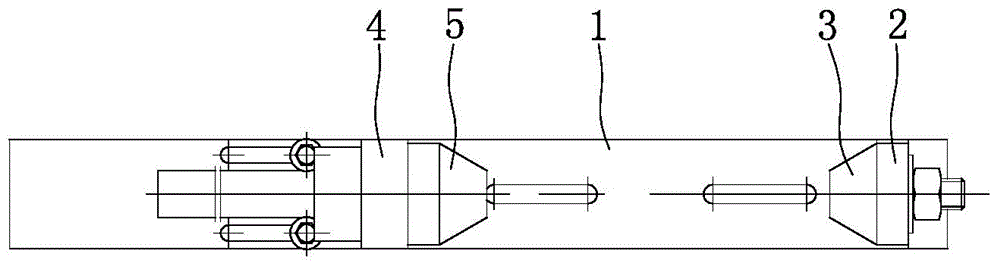

Clamp for welding automobile steering column installation support assembly

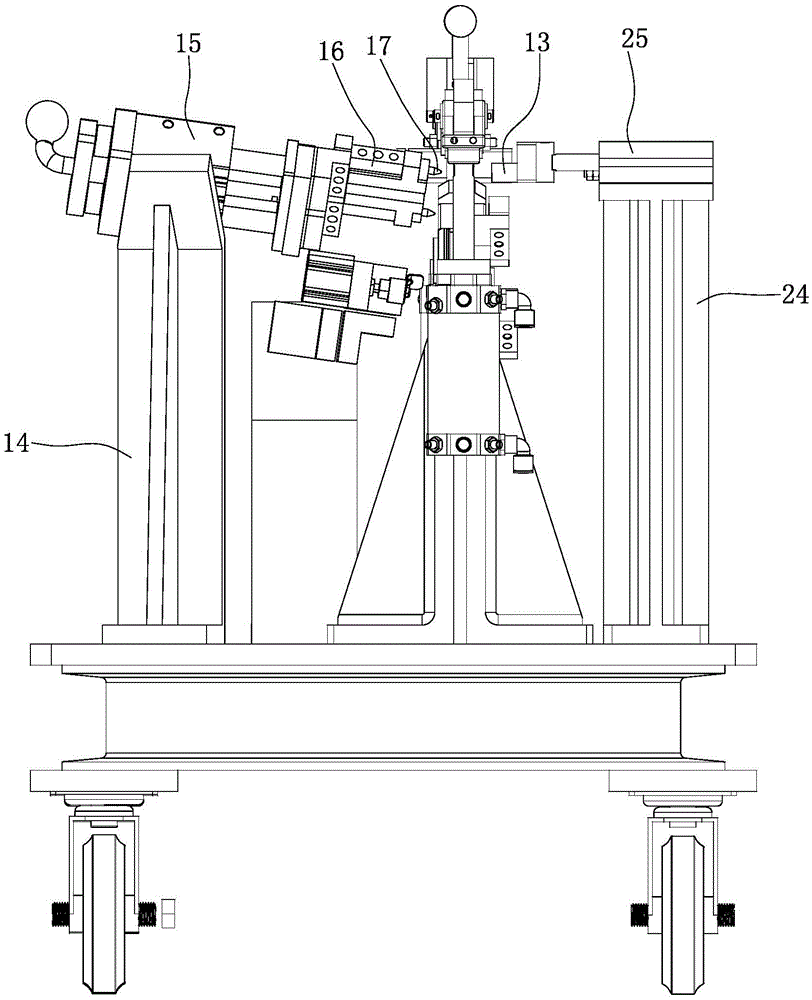

InactiveCN104526226ASimple structureCompact structureWelding/cutting auxillary devicesAuxillary welding devicesSteering columnSteering wheel

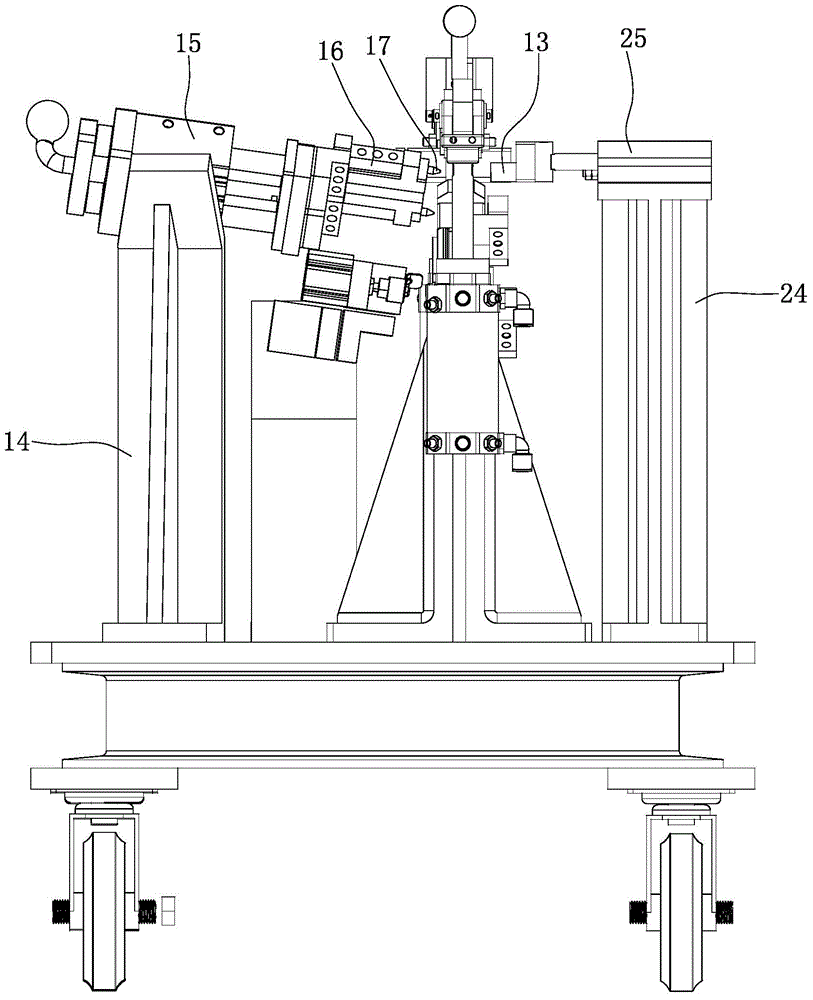

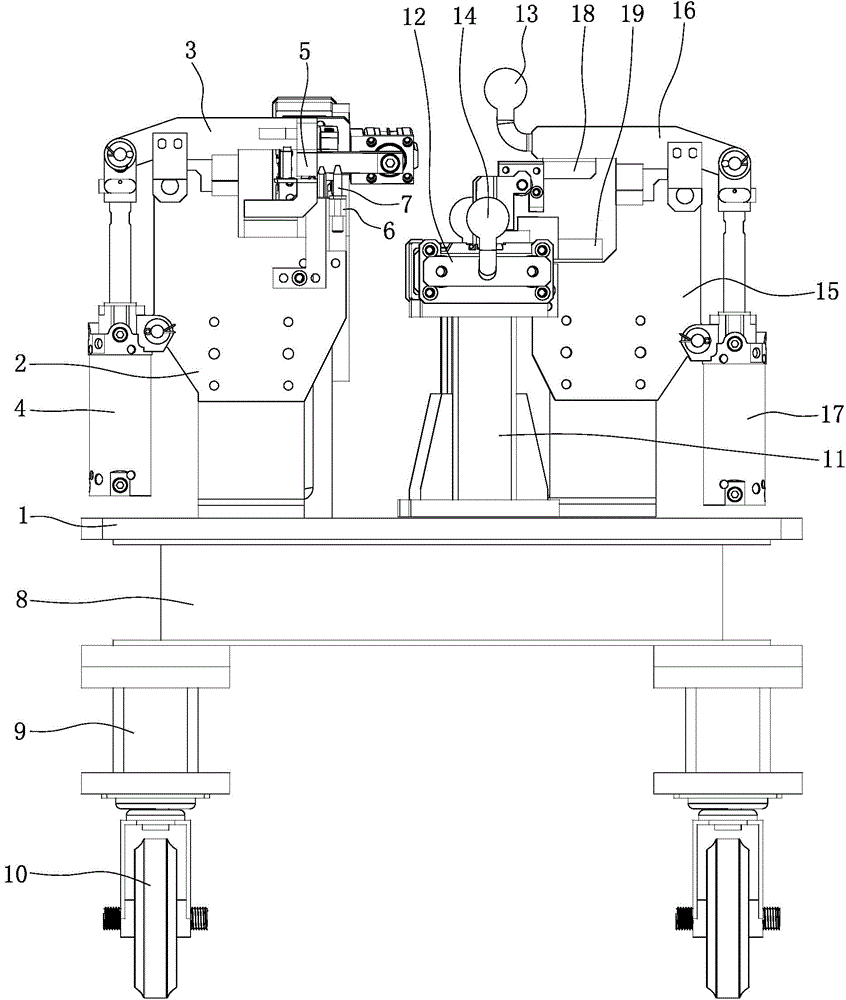

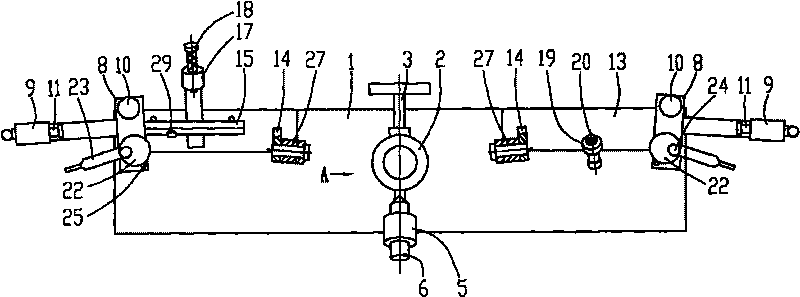

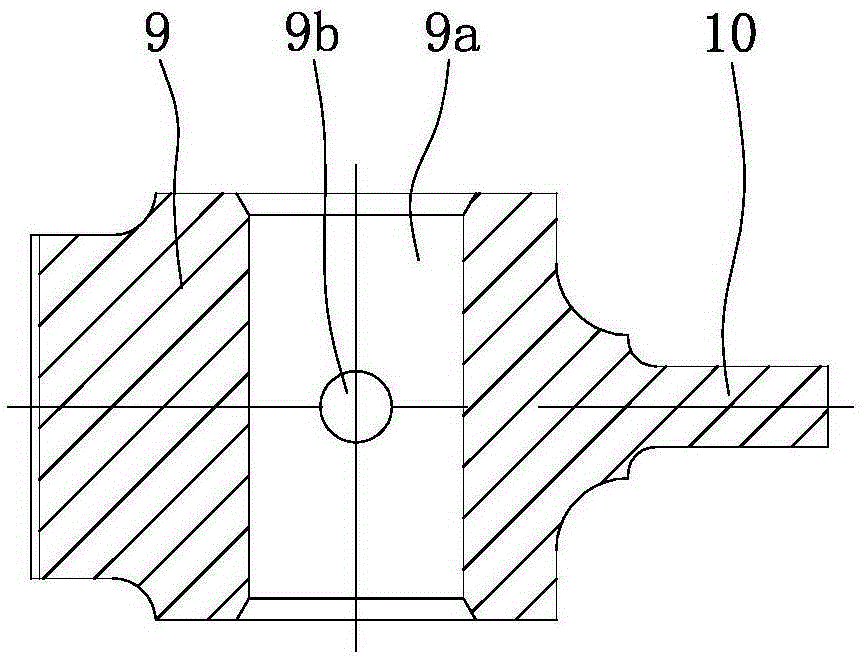

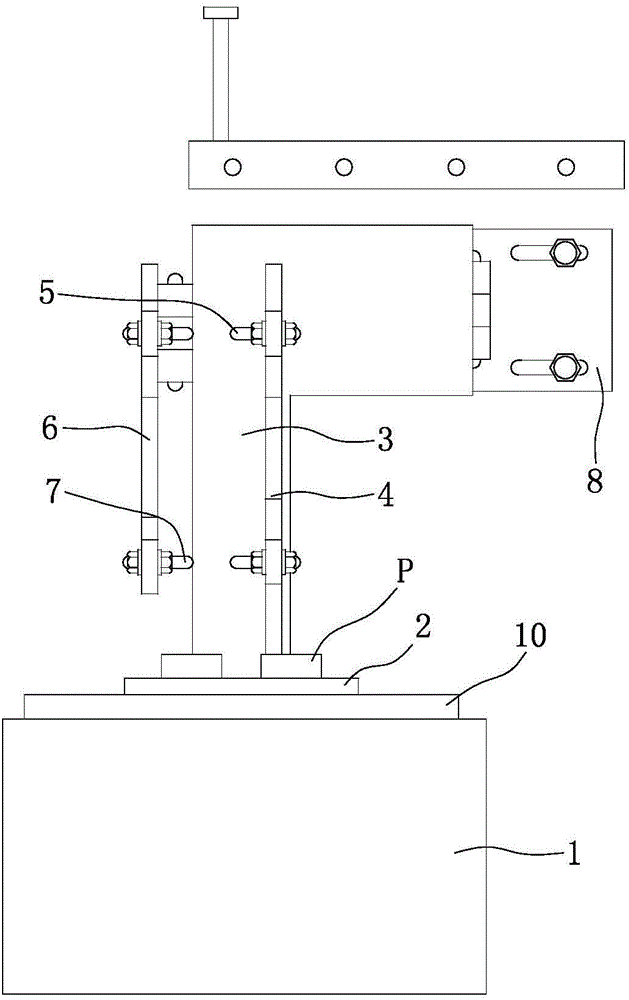

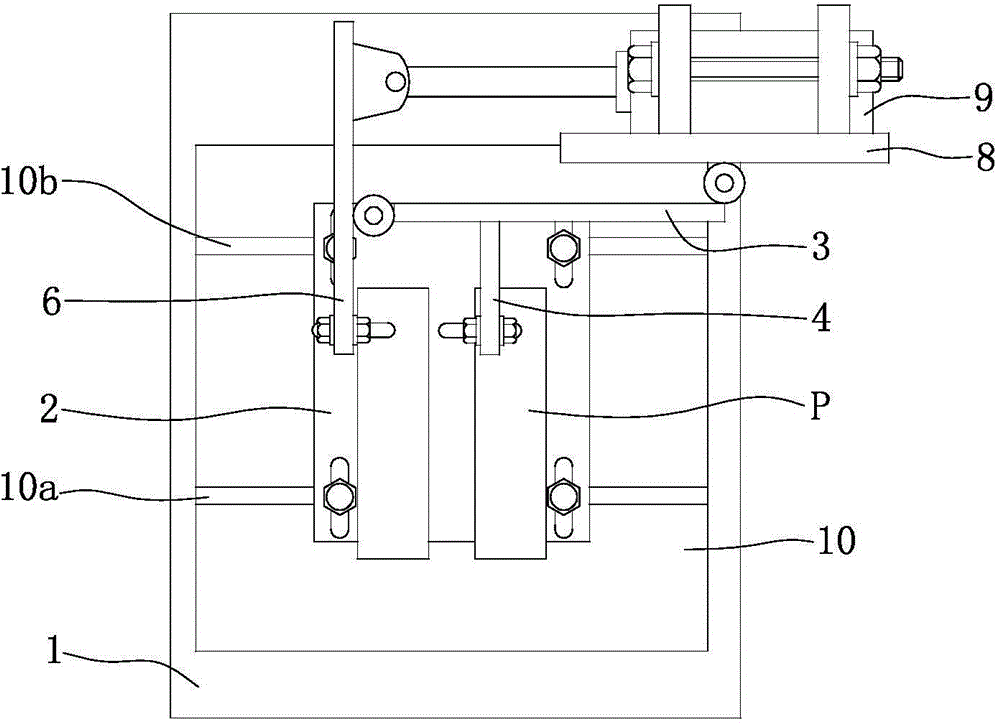

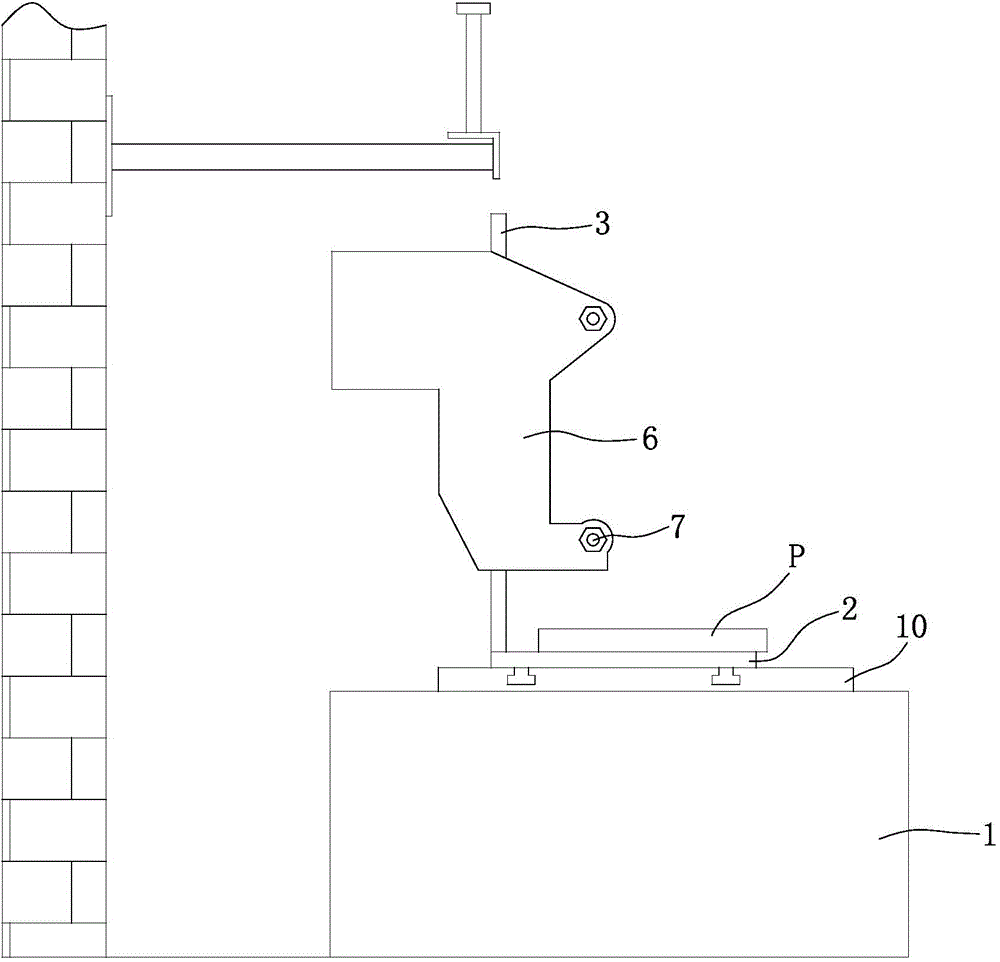

The invention discloses a clamp for welding an automobile steering column installation support assembly. The front end of a front swing arm (3) is hinged to a piston rod of a front clamping cylinder (4), a cross bar (3a) is integrally formed at the rear end of the front swing arm (3), front press blocks (5) are symmetrically are arranged at the bottom of the cross bar (3a), the rear end of a rear swing arm (16) is hinged to a piston rod of a rear clamping cylinder (17), a rear press block (18) is arranged at the bottom of the front end of the rear swing arm (16), the base plate (1) is supported by a bottom frame (8), and square columns (9) are arranged at four corners of the bottom of the bottom frame (8). Welding of the steering column installation support assembly can be achieved through one clamp, and the clamp is simple and compact in structure, easy to assemble and small in occupation space. On one hand, the clamp is reliable in location and capable of ensuring that a steering column installation support and a steering wheel angle installation support are fixed in the welding process, meets the requirement for consistent production; on the other hand, the clamp effectively reduces work procedure, is simple and quick to operate and greatly improves welding efficiency.

Owner:CHONGQING DADONG AUTO PARTS

Check tool for handlebar of curved beam motorcycle

InactiveCN101696868ASpeed up incoming quality inspectionIncoming quality controlAngles/taper measurementsMechanical counters/curvatures measurementsSoftware engineeringCam

The invention relates to a check tool for a handlebar of a curved beam motorcycle, wherein the middle of a bottom plate is fixed with a first positioning column and is provided with a first detection pin; supports are fixed on the left and right ends of the board surface of the bottom board, a first supporting board and a second positioning sleeve are arranged on the top of each supports, the board surface of the first supporting board is provided with a cam mechanism on the front end and a second positioning column on the back end, positioning pins are penetrated into the second positioning sleeves at the left and the right sides; second pillars are arranged between the first positioning column and the left support and between the first positioning column the right support, the top of each second pillar is fixed with a second supporting board, the second supporting board at the left side is provided with a second detection rod, a third supporting board and a second detection pin, and the second supporting board at the right side is provided with a second detection rod and a third detection pin. The invention can greatly improve the speed and the accuracy of quality detection when the handlebars are brought into motorcycle enterprises, ensures the conformation of the quality of the handlebar to requirements, effectively improves handlebar assembling speed and meets the requirement of consistent production.

Owner:力帆科技(集团)股份有限公司

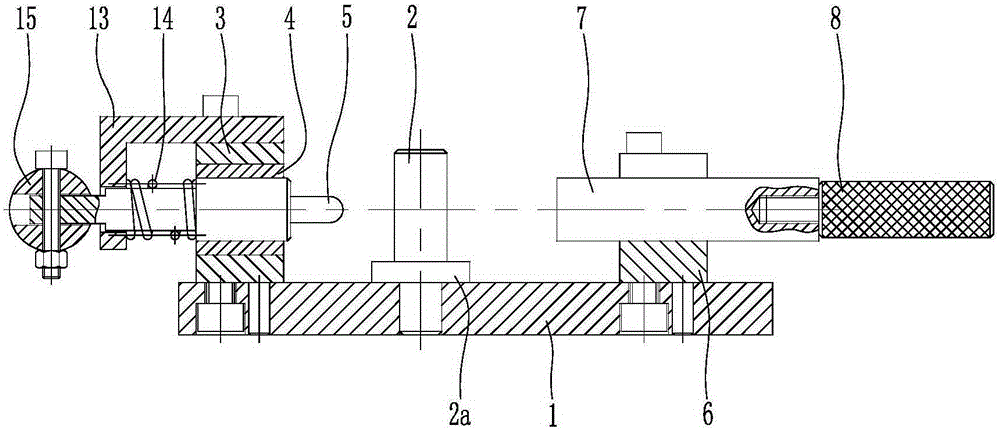

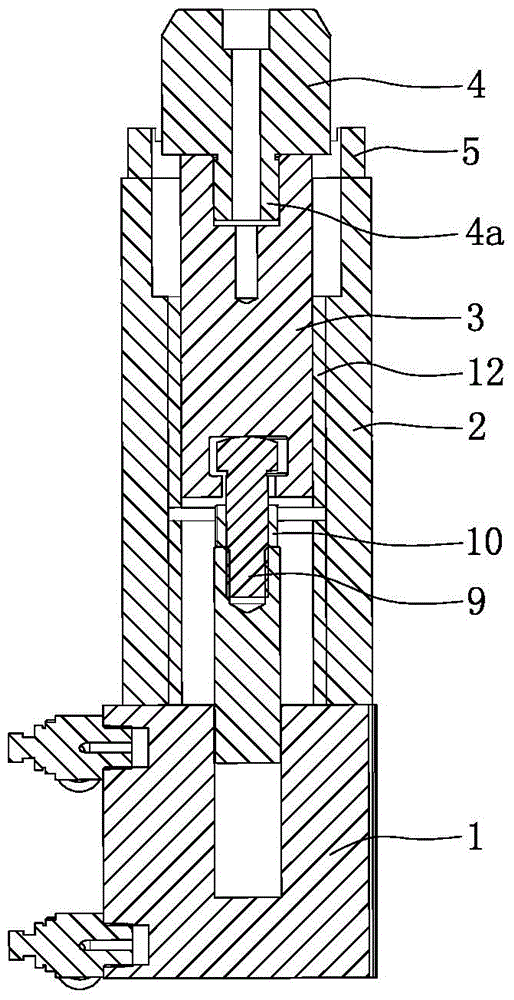

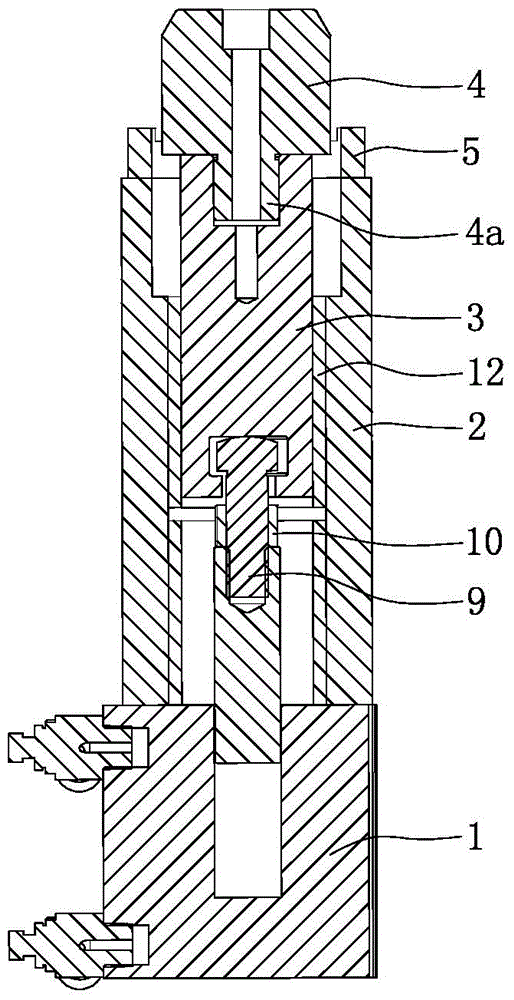

Three-point measurement method for negative clearance of third-generation hub bearing unit

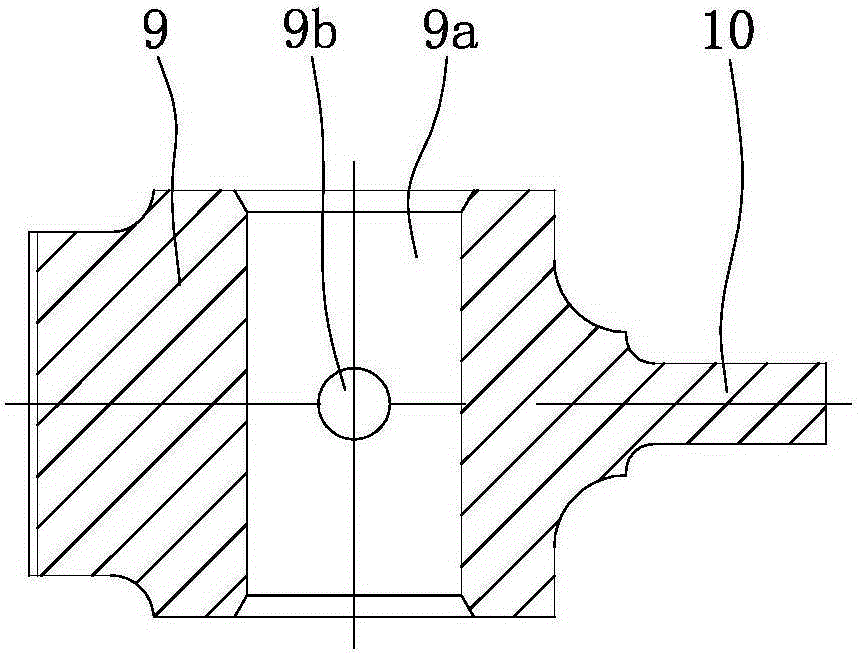

InactiveCN106524977AGuarantee product qualityEasy to operateMechanical measuring arrangementsEngineeringFlange

The invention discloses a three-point measurement method for negative clearance of a third-generation hub bearing unit. The three-point measurement method comprises the steps of: 1) assembling; 2) sleeving a small end surface of a first inner ring on a shaft at the upper end of a second inner ring downwardly, carrying out pre-pressing by applying downward pressure F1 to a large end surface of the first inner ring, so that a distance a is kept between the small end surface of the first inner ring and the shaft shoulder of the second inner ring; 3) applying a force to a flange plate of an outer ring in a sequence from the upper end to the lower end or from the lower end to the upper end, and measuring a positive clearance value Ga by adopting the three-point measurement method; 4) applying downward pressure F2 to the first inner ring, so that the small end surface of the first inner ring is in contact with the shaft shoulder of the second inner ring; 5) and measuring displacement L of the first inner ring moving along the axial direction, if Ga<L, indicating that a negative clearance value equals to Ga-L, and if Ga>L, replacing the first inner ring, and repeating the steps from 1) to 4). The three-point measurement method can be used for measuring the negative clearance value of the third-generation hub bearing unit directly, is simple and convenient in operation, fast in measuring speed, high in efficiency as well as precise and reliable in measurement results, can ensure the quality of subsequent press-fitting products, and satisfies requirement for consistency in production.

Owner:CHONGQING CHANGJIANG BEARING

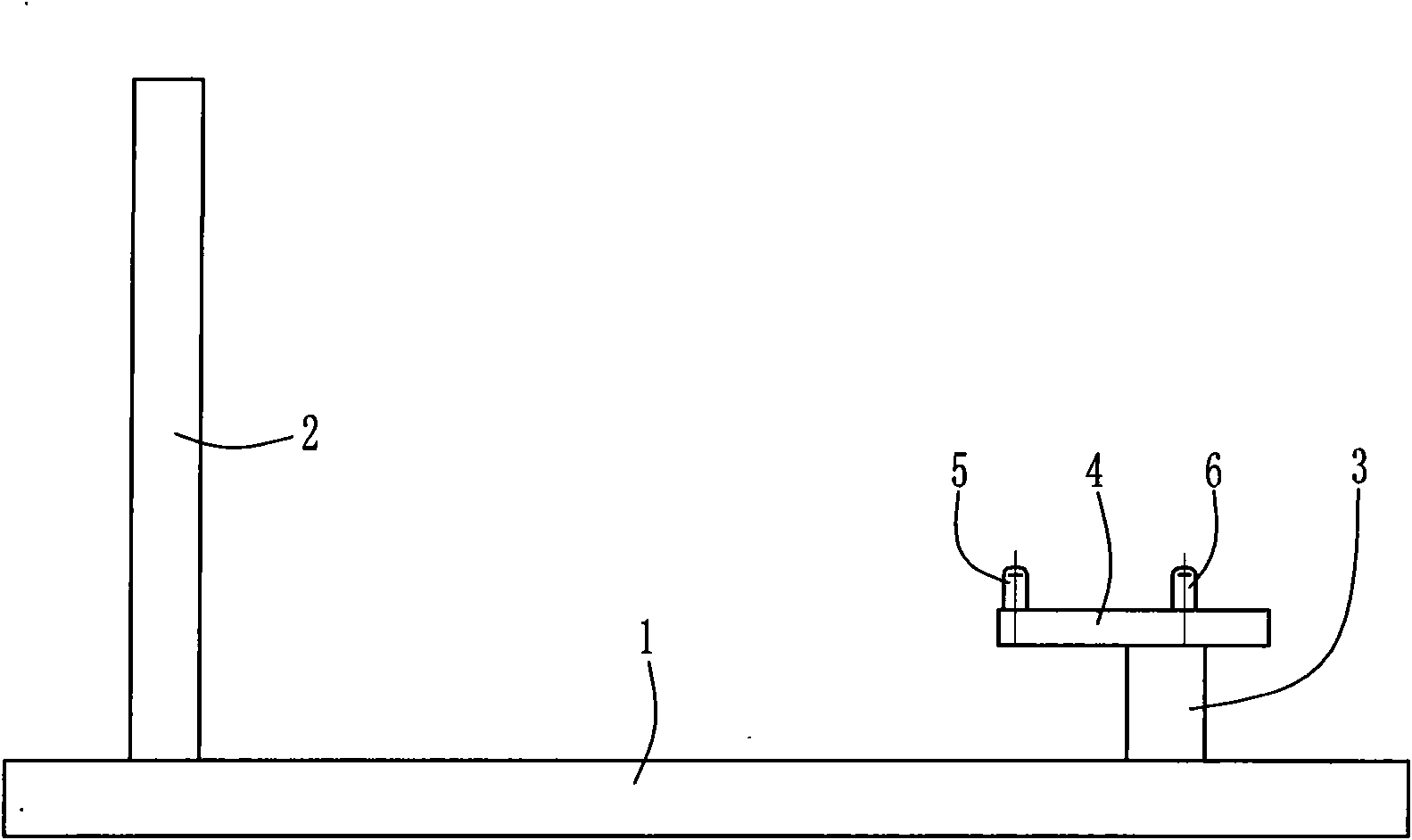

Check tool for front fender

InactiveCN101619955AImprove detection efficiencyHas a guiding roleAngles/taper measurementsMechanical diameter measurementsArchitectural engineering

The invention discloses a check tool for a front fender, which comprises a base, a limit pile, a pillar, a positioning plate, two front positioning columns and a rear positioning column. The limit pile is fixed at the front end of the base and is vertical to the base; the positioning plate is mounted at the rear end of the base through the pillar; the two front positioning columns are arranged at the front end of the upper plate surface of the positioning plate juxtaposedly; a rear positioning column is arranged at the rear part of the upper plate surface of the positioning plate; and the front positioning columns and the rear positioning column are parallel to the limit pile and are distributed in an isosceles triangle. The invention can greatly improve the quality detection speed and the accuracy of the front fender produced by motorcycle enterprises during the ex-factory and ensure that the quality of the front fender satisfies the requirements, thereby effectively improving the assembly speed of the front fender and satisfying the requirements of conformity production. Meanwhile, the installation center of the front fender is ensured and the deflection of the front fender is avoided, thereby the use performance and the decoration effect of the front fender are guaranteed.

Owner:力帆科技(集团)股份有限公司

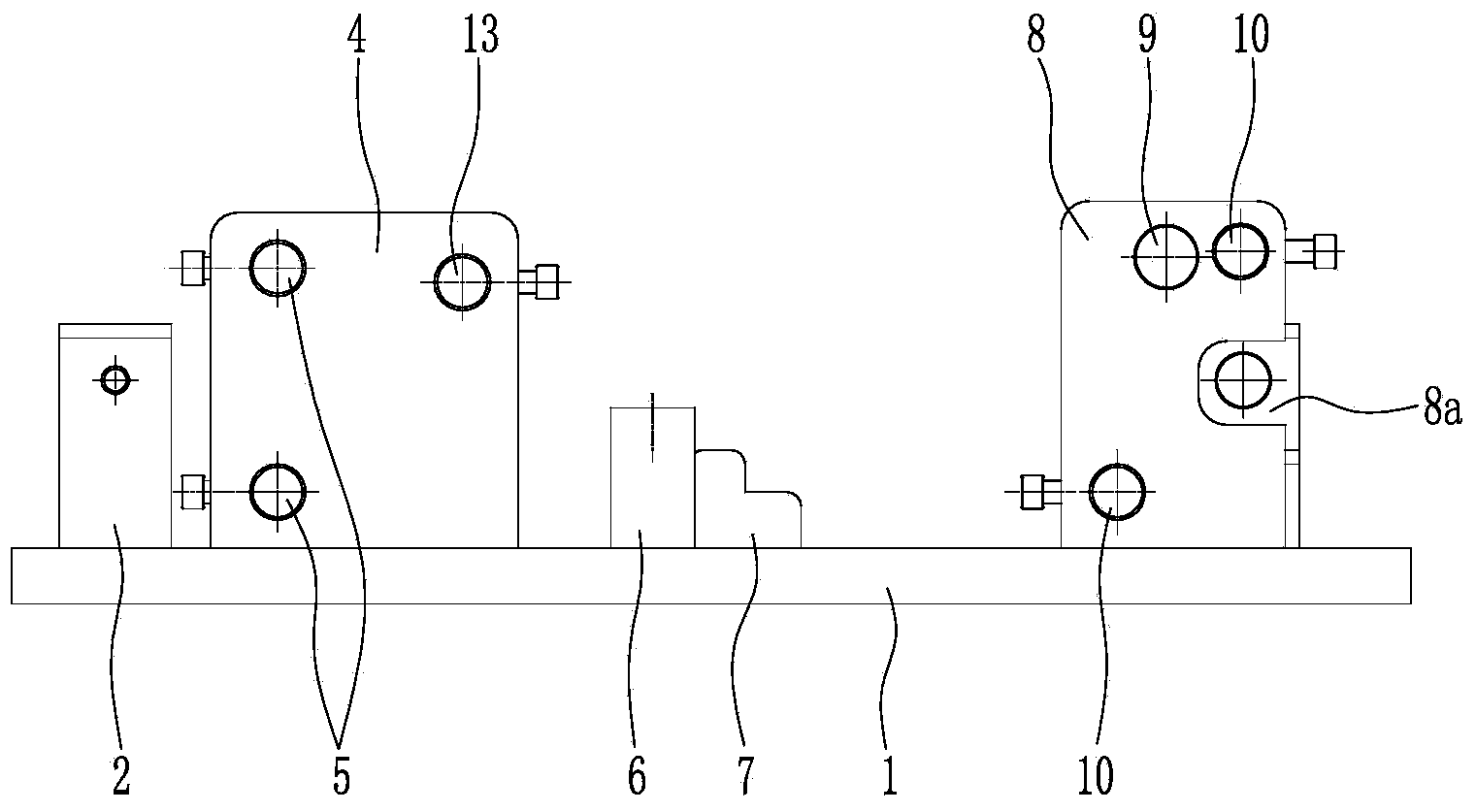

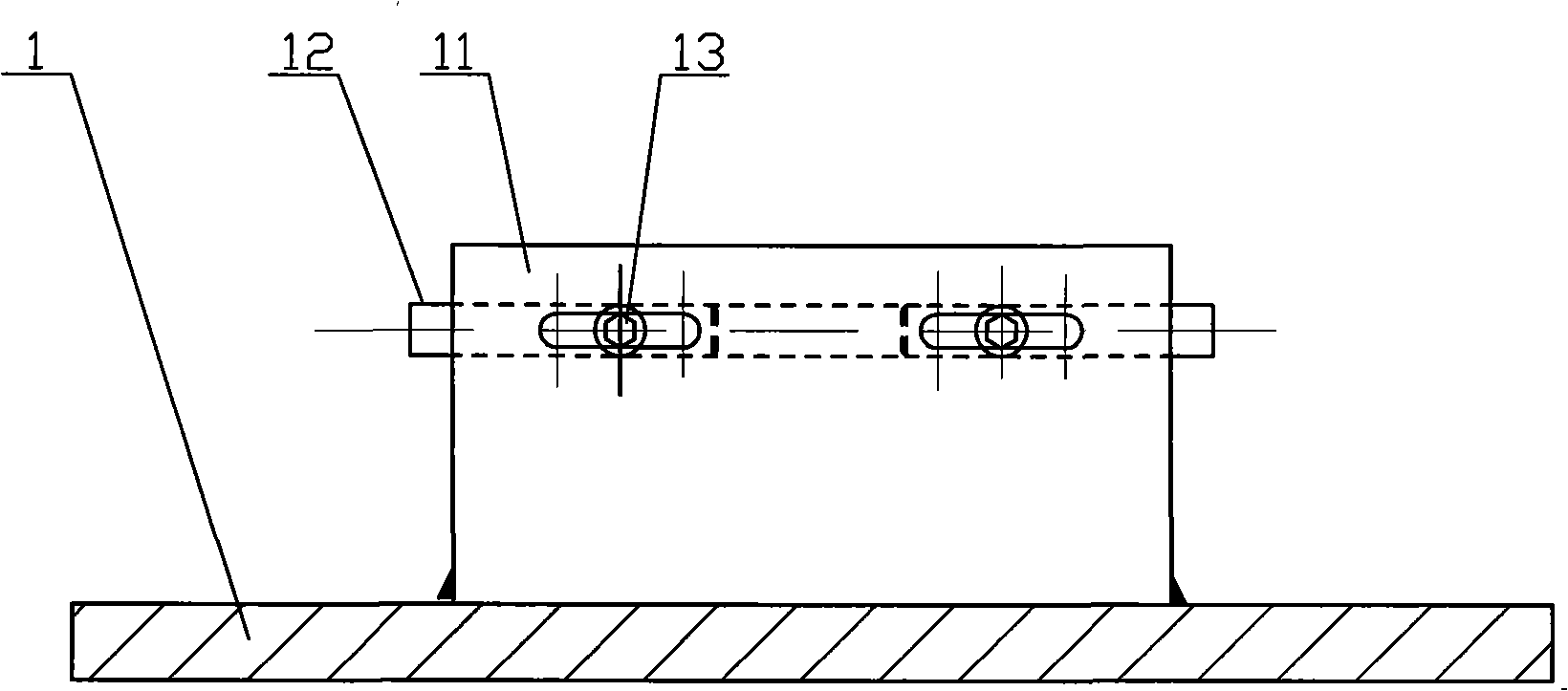

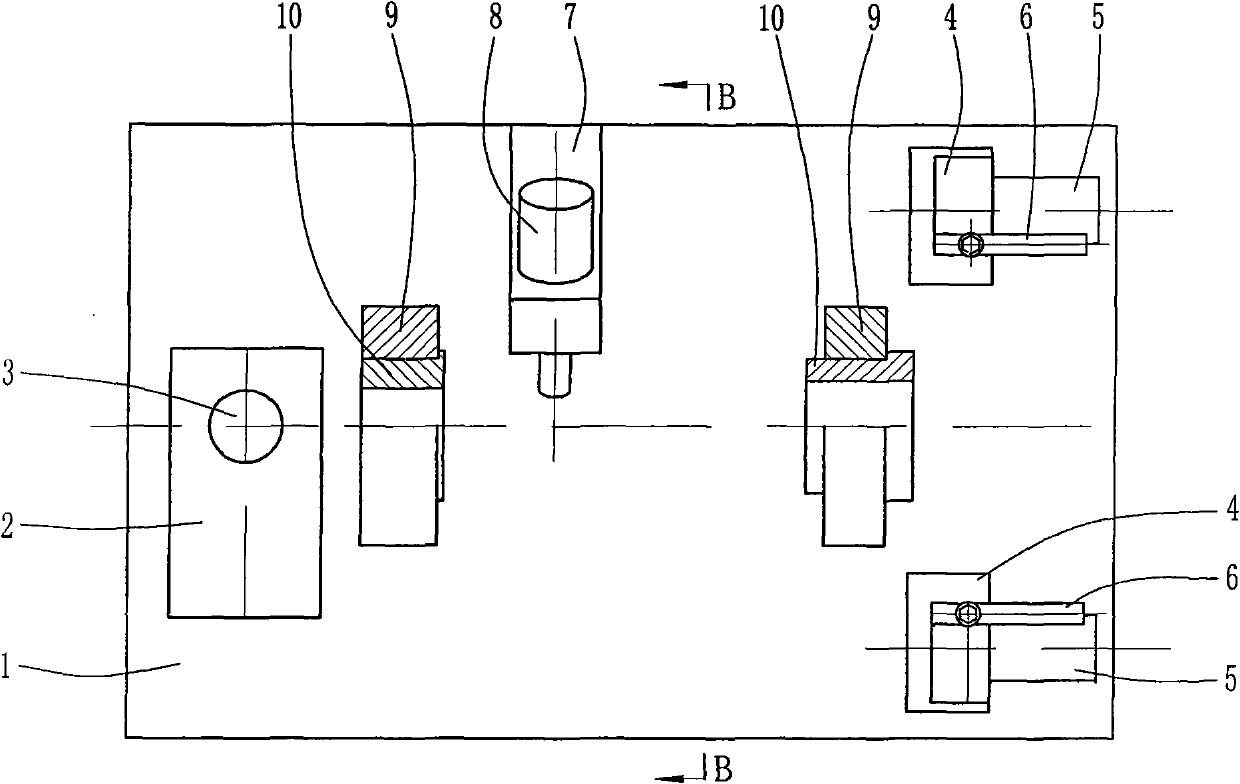

Detecting device of motorcycle rear fork welding assembly

InactiveCN103913101AHigh speedImprove accuracyAngles/taper measurementsAgricultural engineeringCushion

The invention discloses a detecting device of a motorcycle rear fork welding assembly. A rear fork shaft sleeve positioning seat (2) is fixedly arranged at the center of the front end of the upper plate face of a base (1), and a chain box mounting support lug positioning seat (4) is fixedly arranged on the left side of the front portion of the upper plate face of the base (1). A chain protective clamping mounting support lug positioning block (6) is fixedly arranged on the left side of the middle of the upper plate face of the base (1), and a return spring hanging pin detecting block (7) is fixedly arranged on the right side of the middle of the upper plate face of the base (1). Rear cushion mounting shaft positioning seats (8) are symmetrically arranged on the left side and the right side of the rear end of the upper plate face of the base (1), and a rear wheel axle positioning seat (11) is arranged between the two rear cushion mounting shaft positioning seats (8). The detecting device of the motorcycle rear fork welding assembly has the advantages of being simple in structure, easy to implement, convenient and quick to operate, and capable of greatly improving the quality inspection speed and accuracy of motorcycle enterprises when the rear fork welding assembly enters a factory, ensuring that the quality of the rear fork welding assembly can meet requirements, effectively increasing the assembling speed of the rear fork welding assembly, and meeting the consistency production requirement.

Owner:力帆科技(集团)股份有限公司

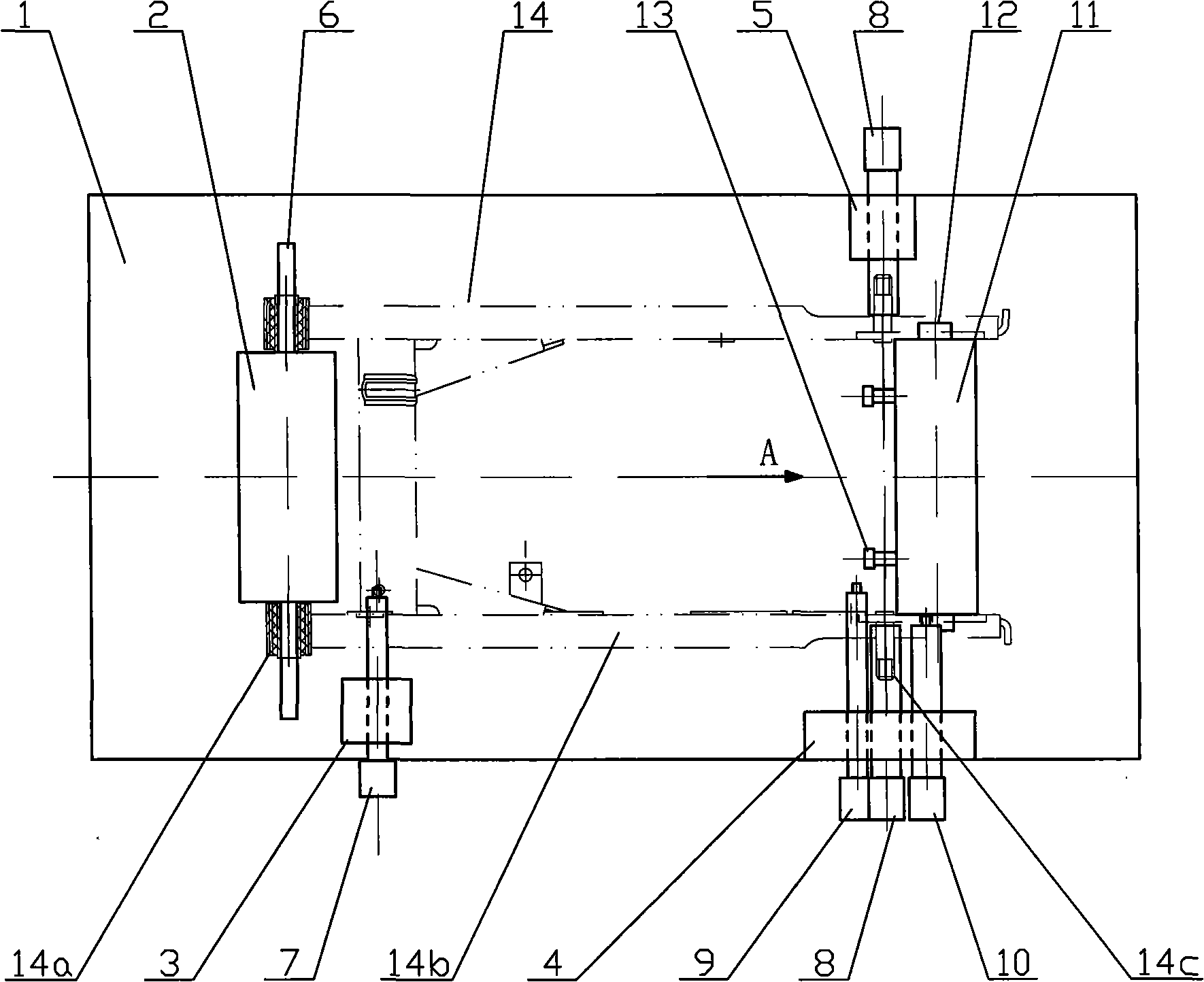

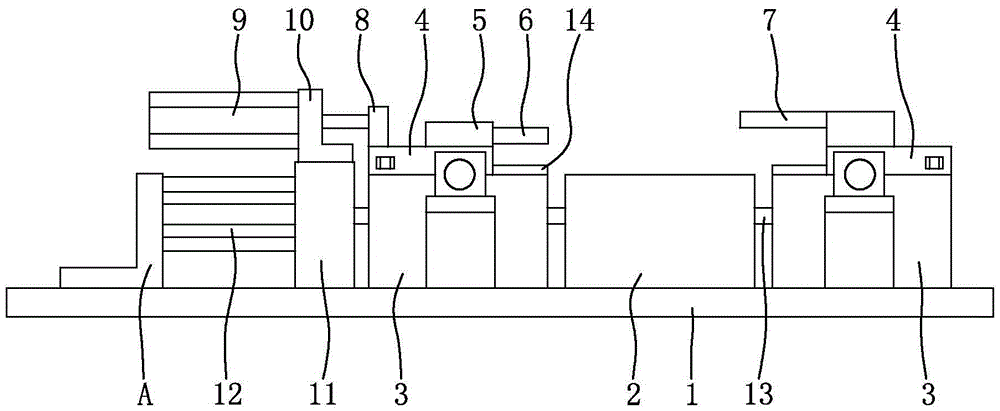

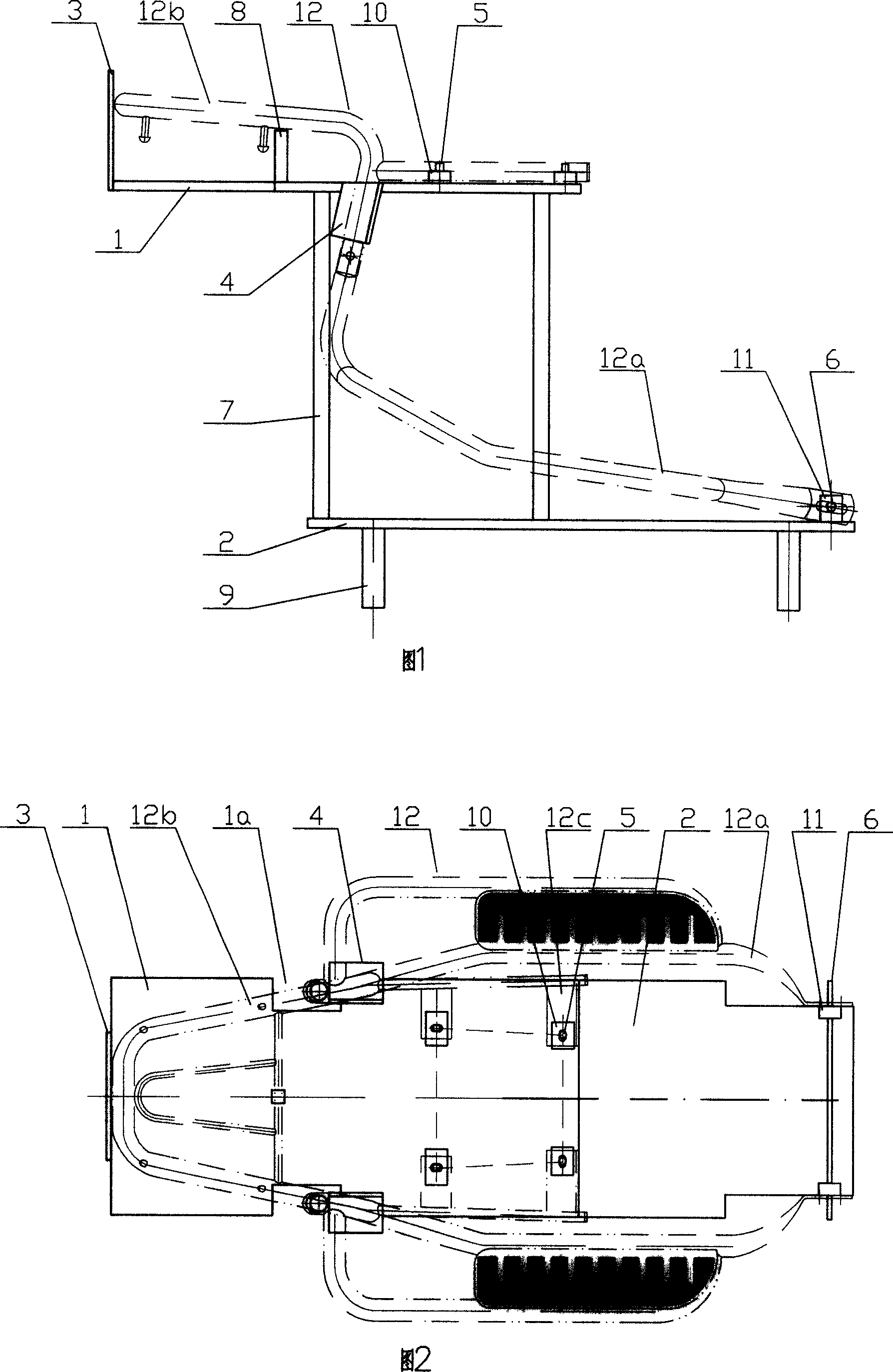

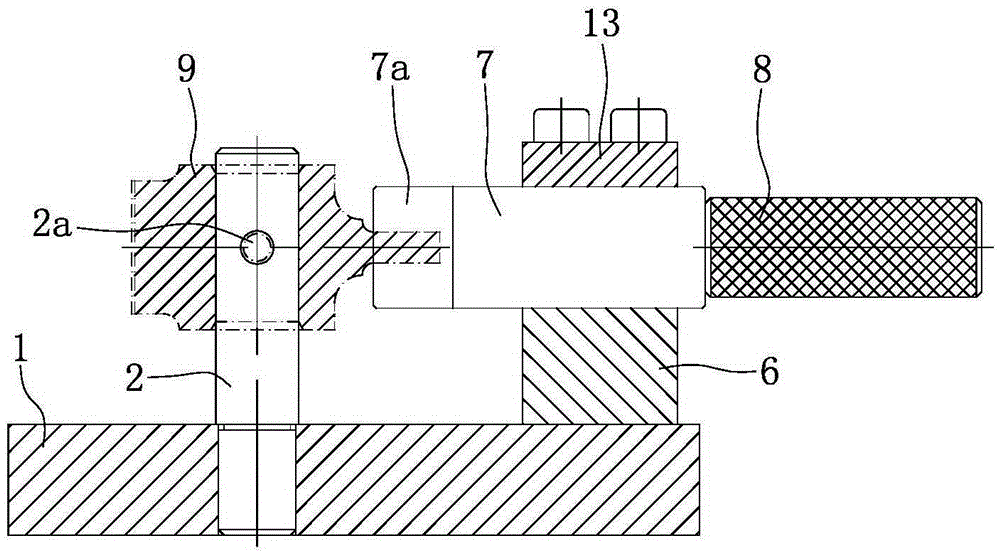

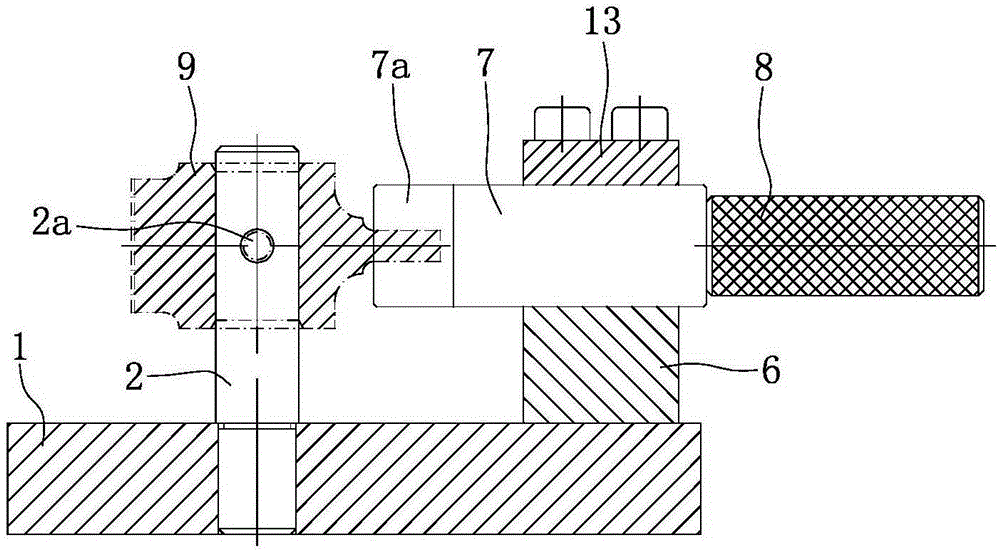

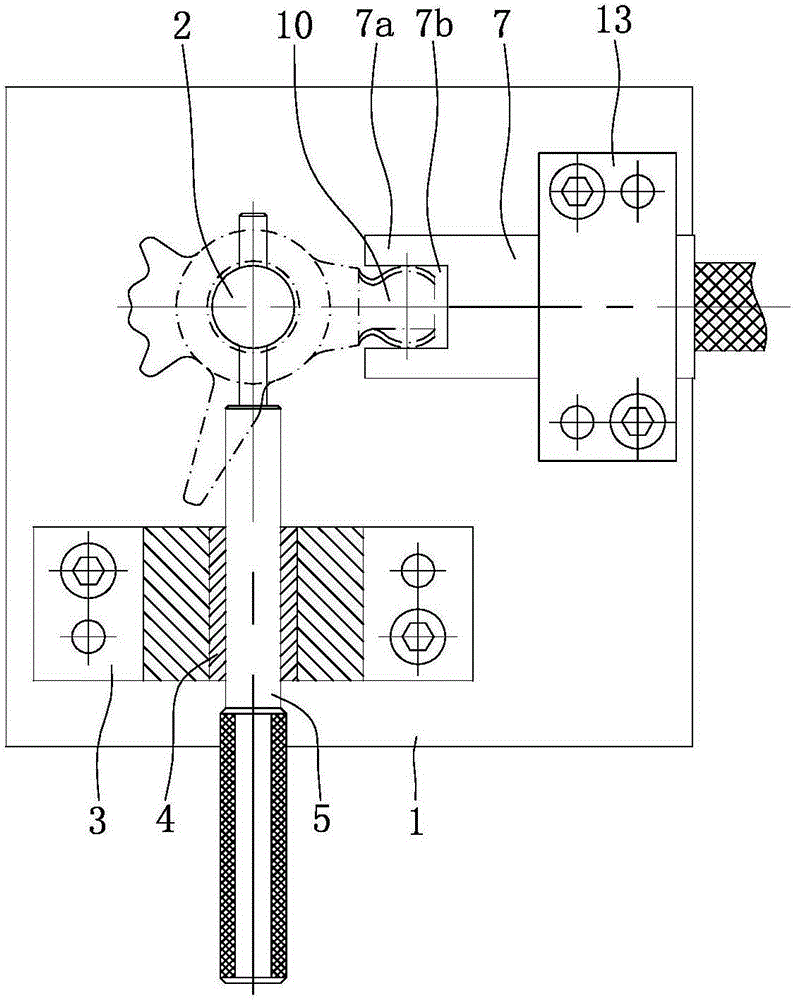

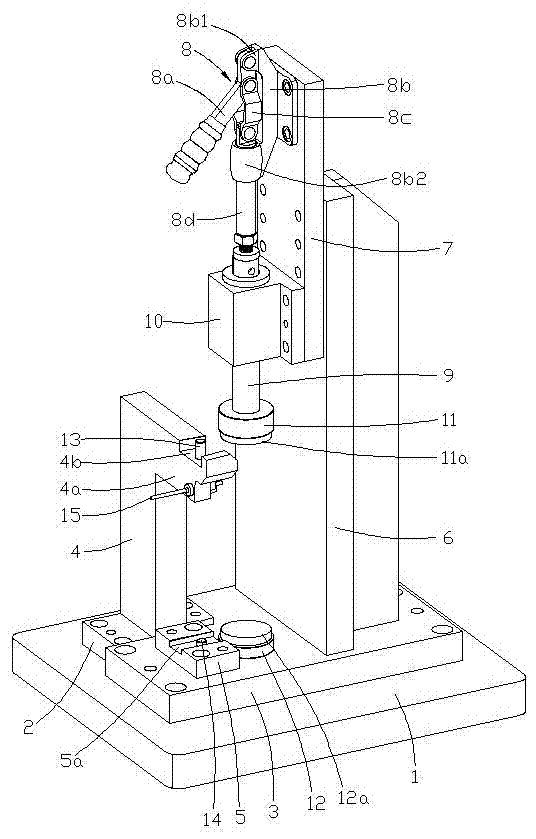

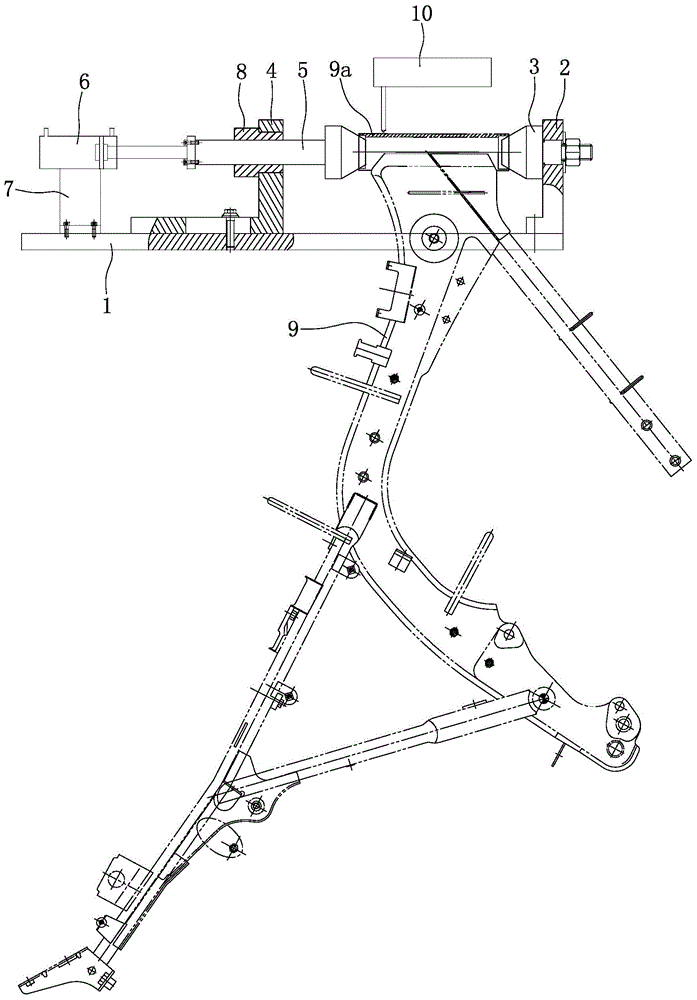

Support device for rear axle assembly of automobile production line

InactiveCN102489985AReduce labor intensityGuaranteed Accuracy and ReliabilityMetal working apparatusProduction lineUltimate tensile strength

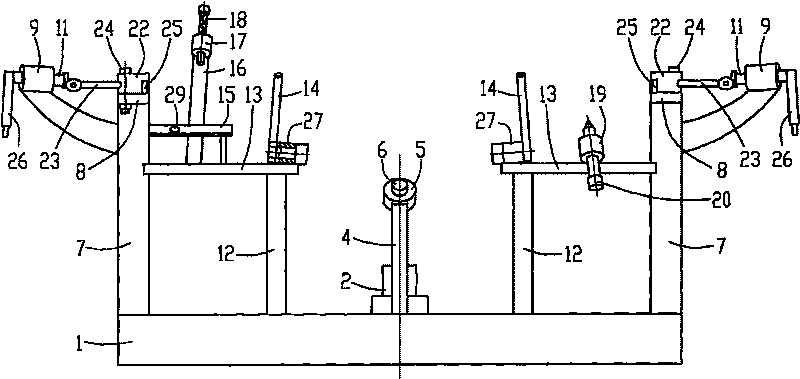

The invention discloses a support device for a rear axle assembly of an automobile production line. An intermediate support mechanism and lateral support mechanisms are arranged on a bottom plate (1); the intermediate support mechanism comprises a base (2), an upright post (3), a first support post (4), a first sleeve (5), a first positioning plate (6), positioning rods (7) and the like; and each lateral support mechanism comprises a rectangular tube (9), a positioning pin (10), a second positioning plate (11), a support (12), a first support post (13), a second sleeve (14), a bearing seat (15), a lifting platform (16) and the like. The assembly of the automobile rear axle assembly can be facilitated, assembly difficulty is reduced, assembly quality and assembly efficiency are effectively improved, the number of the required operators is reduced, the labor intensity of workers is greatly reduced, the requirement of consistent production is met, and the support device has the characteristics of high safety and reliability, wide application range and the like, and is easy to operate.

Owner:力帆科技(集团)股份有限公司

Rear fork detecting fixture of motorcycle

InactiveCN101315265AEasy to placeEvenly placedVehicle testingMechanical measuring arrangementsEngineeringMechanical engineering

The invention discloses a detection tooling apparatus for a rear fork of a two-wheeled motorcycle. A front positioning seat is fixed at the front part of a base, through-holes penetrating left and right end surfaces are formed on the front positioning seat, and positioning shafts are inserted into the through-holes; a left front positioning seat is positioned on the left side of the rear part of the front positioning seat, an upper through-hole and a lower through-hole which respectively penetrate the left and the right end surfaces are formed on the left front positioning seat, and a first positioning pin is inserted in each through-hole from outside to inside; a left rear positioning seat and a right rear positioning seat are positioned at left and right ends of the rear part of the base, second positioning pins are inserted into the upper parts of the left rear positioning seat and the right rear positioning seat from outside to inside, positioning holes penetrating the inner end surface of the second positioning pin are formed at the inner end thereof, and a third positioning pin and a fourth positioning pin are respectively arranged on front and rear sides of the second positioning pins at the left end. The detection tooling apparatus can greatly improve the rate and the accuracy of the quality detection when the rear fork enters a factory of a motorcycle manufacturer, ensure that the quality of the rear forks meet the requirements, effectively improve the assembly speed of the rear fork and meet the requirement of uniform production.

Owner:力帆科技(集团)股份有限公司

Pneumatic device for welding and positioning of intake manifold lower cover and middle cover

ActiveCN105458593ASimple structureSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSlide plate

The invention discloses a pneumatic device for welding and positioning of an intake manifold lower cover and a middle cover. A die holder is mounted on a bottom plate, the left side and the right side of the die holder are provided with fixing seats, the fixing seats are in a flat-base-U shape, the tops of the fixing seats are provided with sliding plates respectively, an adapter block is mounted on each sliding plate, the right end of the corresponding adapter block on the left side is fixedly provided with a pressing plate, the left end of the corresponding adapter block on the right side is fixedly provided with a base plate, the corresponding sliding plate on the left side is provided with a locking block, the corresponding locking block is connected with a piston rod of a push-pull air cylinder, a cylinder body of the corresponding push-pull air cylinder is fixed to a connection block, each connection block is arranged at the top of a base in a supported mode, the base is provided with a rotating air cylinder, the output end of the rotating air cylinder is connected with a lead screw, the lead screw is sleeved with a nut seat, and the nut seat is fixed to the bottom of the corresponding sliding plate on the right side. The pneumatic device is easy to assemble, low in cost, flexible and fast to operate and capable of effectively improving welding efficiency; meanwhile, positioning reliability is good, and welding quality can be guaranteed.

Owner:CHONGQING ANBIXIN AUTOMOBILE INTAKE SYST CO LTD

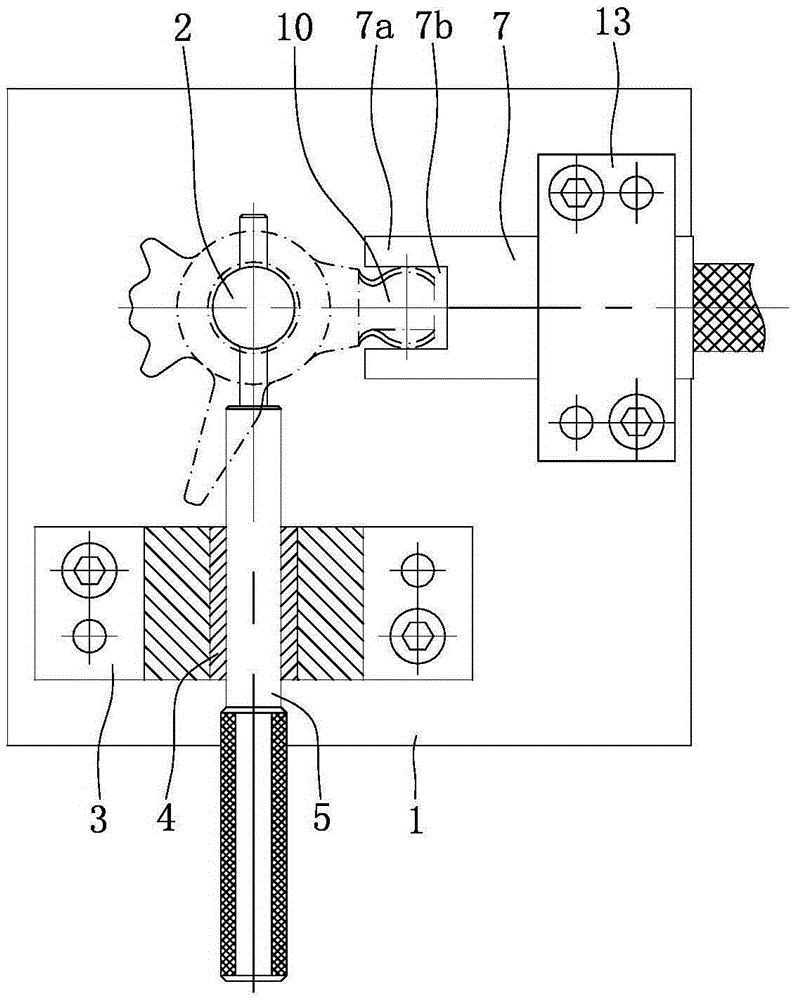

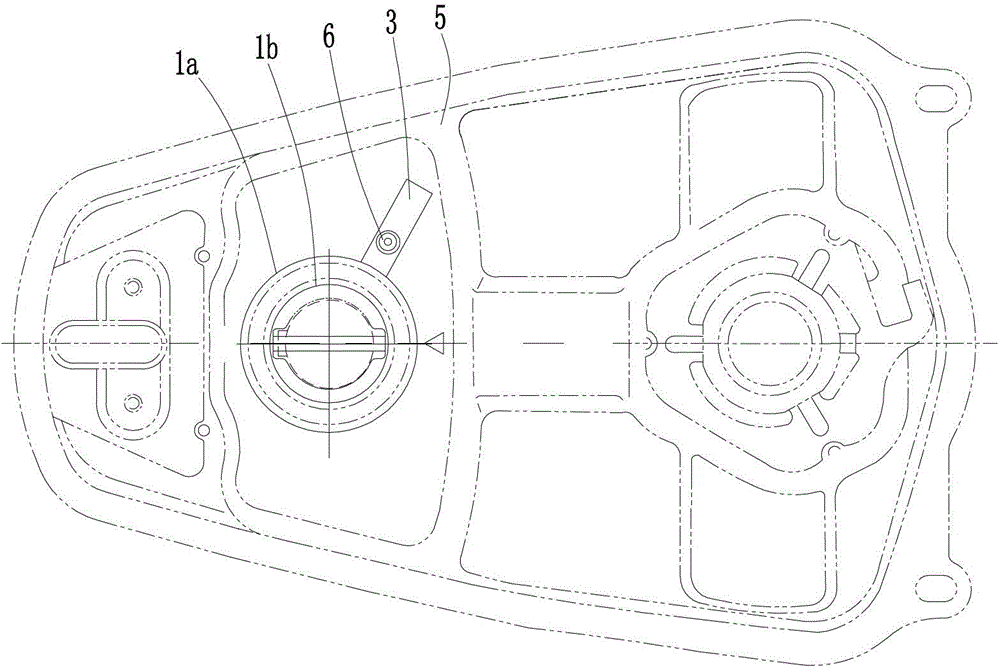

Test method for positions of gearshift swing lever wavy surface ball grooves of automobile gear box

InactiveCN105241335ASimple structureFew partsMechanical measuring arrangementsTest efficiencyEngineering

The invention discloses a test method for positions of gearshift swing lever wavy surface ball grooves of automobile gear box. The test method comprises the following steps: 1) sleeving a positioning shaft with a shaft bush of the gearshift swing lever; 2) releasing an operating handle, the right end of a positioning pin abutting against a first ball groove of the wavy surface; 3) manipulating a first measuring block to move leftward, if a ball head can be clamped in a clamping groove in the left end of the first measuring block, then the position of the first ball groove of the gearshift swing lever wavy surface meets the requirement; 4) enabling the positioning pin loosen the push of the gearshift swing lever, and making a second ball groove of the gearshift swing lever wavy surface face the positioning pin; 5) the right end of the positioning pin abutting against the second ball groove of the wavy surface; 6) manipulating a second measuring block to move leftward, if the ball head can be clamped in a clamping groove in the left end of the first measuring block, then determining that the position of the second ball groove of the gearshift swing lever wavy surface meets the requirement. The test method can be used for testing the positions of two ball grooves of gearshift swing lever wavy surface; the test procedure is simple, the test result is accurate and reliable, and the test efficiency is high.

Owner:CHONGQING YINGQUAN STANDARD PARTS

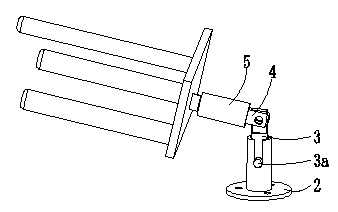

Motorcycle direction column check tool

InactiveCN101644558AInhibit sheddingHigh speedMechanical diameter measurementsArchitectural engineering

The invention relates to a motorcycle direction column check tool. A right angle shape support plate is arranged on the board at the left end of a bottom board, the vertical bottom section of the support plate is fixed with the bottom board, a first location pin is arranged at the horizontal board section of the support plate in penetrating way from up to down; the opposite sides of the front andrear parts of the board at the right end of the bottom board are provided with a first support, the right end face of each first support is fixed with a location column, and the top of the first support is provided with a 'right angle' shape location support; the middle part of the board at the rear end of the bottom board is provided with a location strip, the bottom of the location strip is fixed with the bottom board, the front end of the location strip inclines forward, and the front part of the location strip is provided with a second location pin in penetrating way from back to front; and the left and right sides of the second location pin are all provided with a second support, each second support is provided with a shaft sleeve, and the axes of the two shaft sleeves are collinear.The invention can greatly improve speed and accuracy of quality detection when direction columns are transported to motorcycle enterprise, the quality of the direction column is ensured to meet requirement, speed in direction column assembly is effectively improved, and requirement of consistent production is met.

Owner:力帆科技(集团)股份有限公司

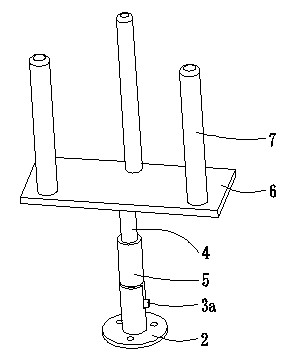

A front and rear pressing and positioning device for welding automobile steering support reinforcement bracket assembly

InactiveCN104511710BGuaranteed accuracyPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a front-and-back compressing and positioning device used for welding an automobile steering support reinforcing stand assembly, a head supporting seat (2) is arranged at the front end of a bottom plate (1), the top of the head supporting seat (2) is articulated with a front swing arm (3), the rear end of the front swing arm (3) is equipped with a front pressing block (5), and an upper positioning pin (6) is arranged on the front pressing block (5) in a penetrated manner; a tail supporting seat (18) is arranged at the rear end of the bottom plate (1), the top of the tail supporting seat (18) is articulated with a rear swing arm (19), a rear pressing block (21) is arranged at the bottom of a front end of the rear swing arm (19), and a rear positioning pin (22) is arranged on the rear pressing block (21) in a penetrated manner. The device is ingenious in design and reasonable in arrangement, and has a simple and compact structure, on the one hand, the device positions accurately and reliably, can lead an up-and-down reinforcing frame and a thread stand to be fixed in the welding process through a fixture, guarantees the welding quality, and meets the requirement for consistency production; on the other hand, the device reduces the working procedure effectively, is simple and quick to operate, and greatly improves the welding efficiency.

Owner:CHONGQING DADONG AUTO PARTS

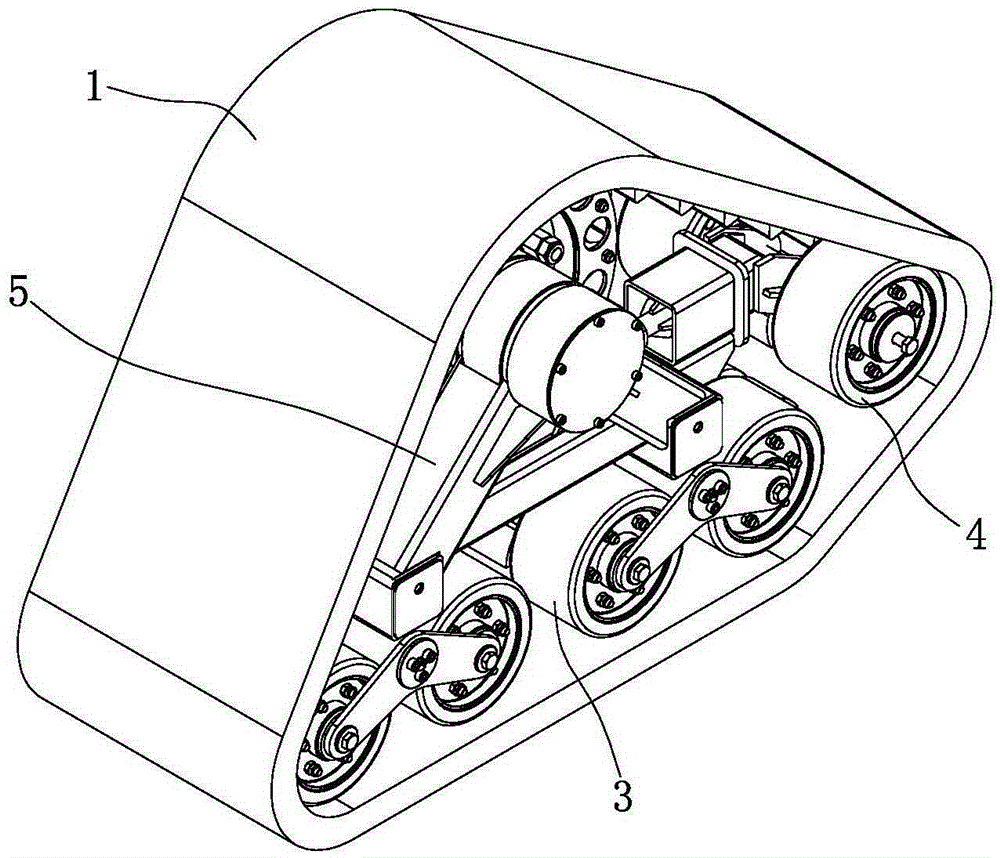

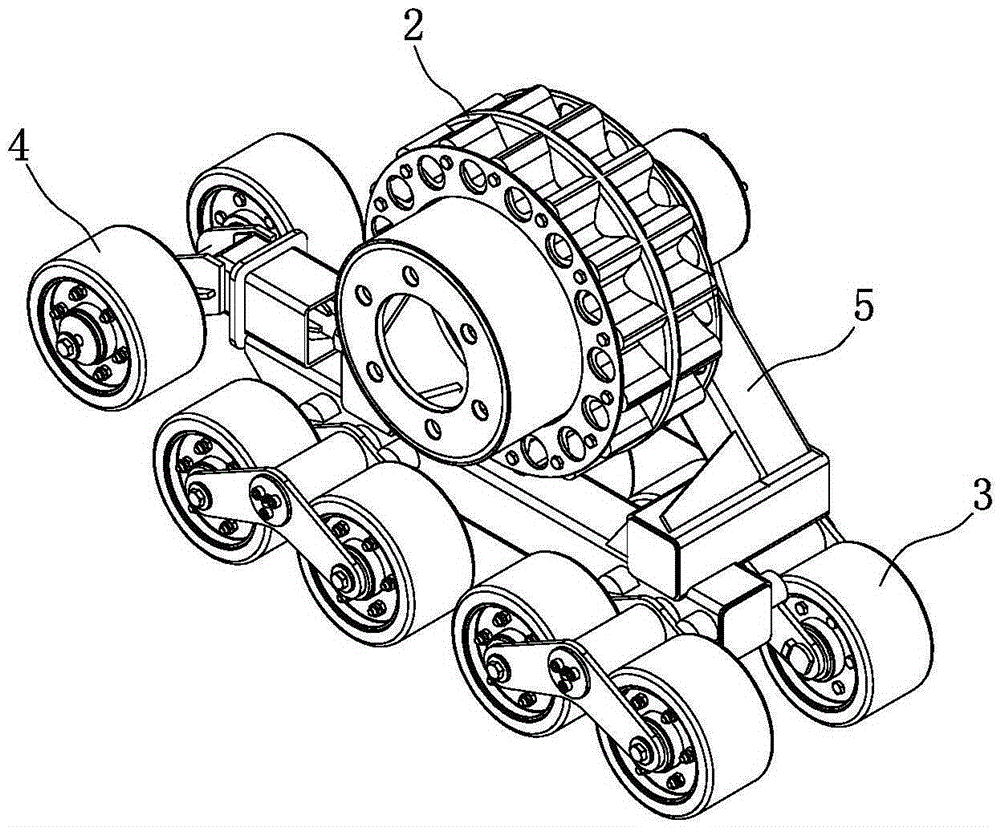

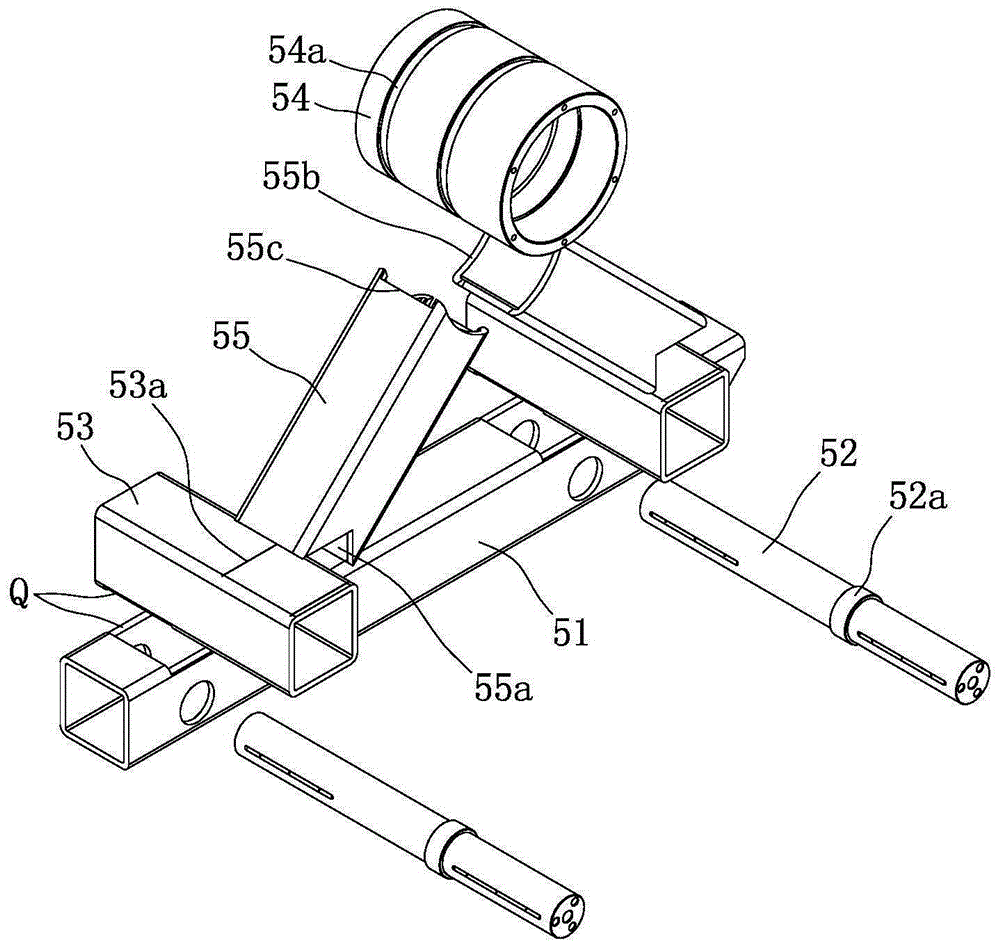

Single-chain driven rear caterpillar track assembly

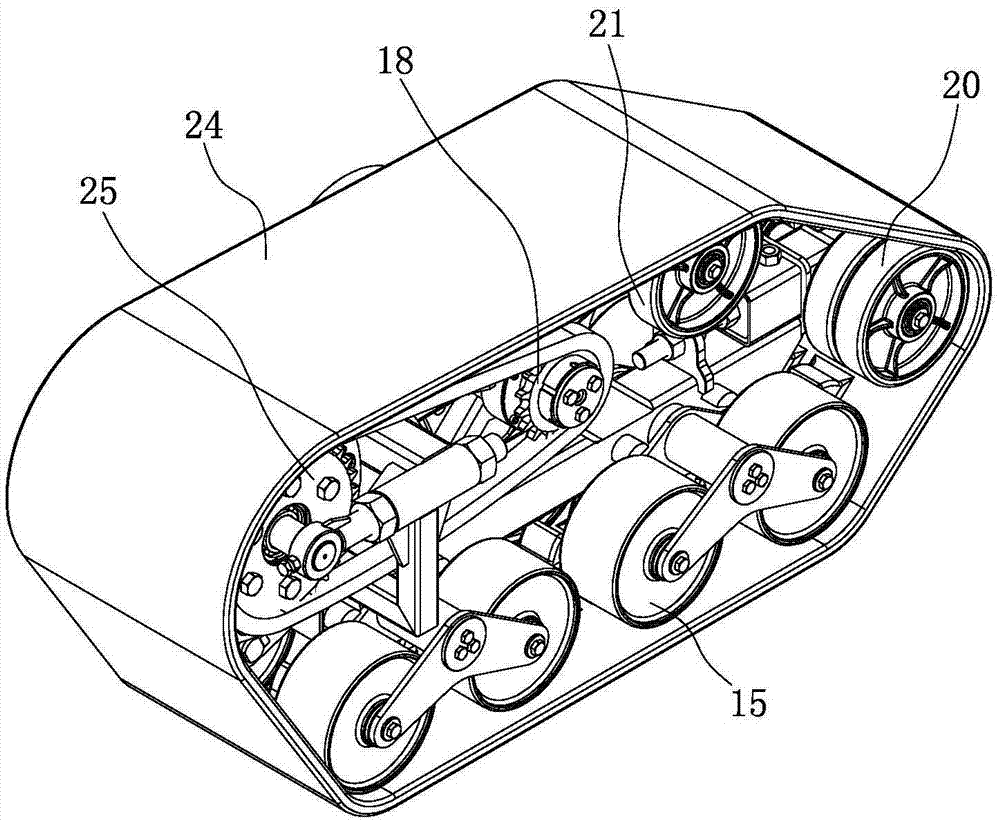

InactiveCN105438296AImprove structural strengthImprove structural stabilityEndless track vehiclesTerrainDrive wheel

The invention discloses a single-chain driven rear caterpillar track assembly. Free wheel axles are transversely arranged at the front end and the rear end of a longitudinal beam in a penetrating mode, a bearing chamber is arranged above the middle of the longitudinal beam, a front inclined supporting beam and a rear inclined supporting beam are symmetrically arranged between the bearing chamber and the longitudinal beam, and a front free wheel and a rear free wheel are mounted at the two end of each free wheel axle. A driving wheel is arranged on the rear side of a driving wheel support upper cross beam and is connected with the free wheels, tensioning wheels and supporting wheels through a rubber caterpillar band, a driven chain wheel is arranged on one side of the driving wheel, a driving wheel axle is sleeved with the driven chain wheel, and the driven chain wheel is connected with the driving chain wheel through a chain. The framework of the single-chain driven rear caterpillar track assembly can ensure position and size accuracy through mutually matched positioning structures among the parts, the structural strength and stability of the whole framework can be good, the welding precision is guaranteed, the reliability is good, the manufacturability of assembly manufacture is good, and the single-chain driven rear caterpillar track assembly has low-speed, heavy-load and smooth and steady characteristics and terrain adaptability.

Owner:CHONGQING TECHU NEW ENERGY

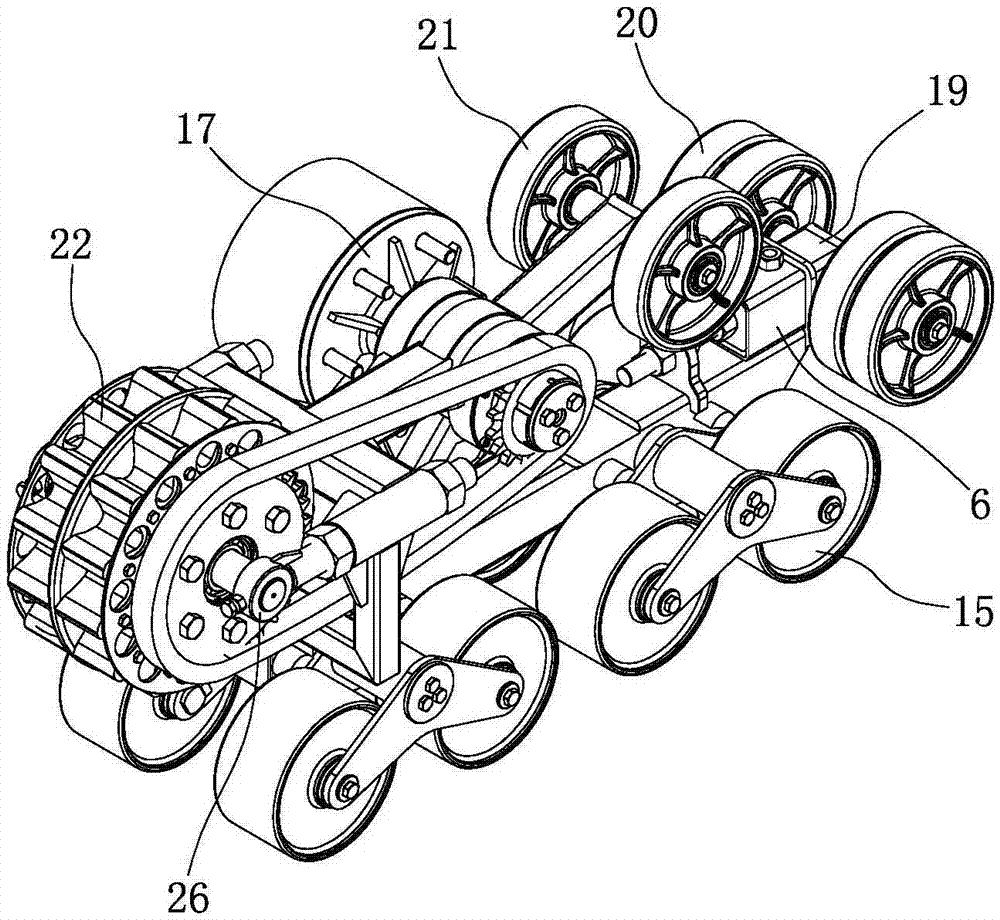

Triangular rear crawler belt assembly

InactiveCN105416424AImprove carrying capacitySave materialEndless track vehiclesEngineeringLow speed

The invention discloses a triangular rear crawler belt assembly. Tensioning wheels are connected with a driving wheel and dissociation wheels through a rubber crawler belt, outer teeth on the circumferential face of the driving wheel are meshed with inner teeth of the inner surface of the rubber crawler belt, steel baffles are installed on the two end faces of the driving wheel in an attached mode, and long bolts penetrate through assembling holes in the two steel baffles and via holes in the outer teeth, so that the two steel baffles and the driving wheel are fixedly connected together; an inner end of a driving main shaft is arranged in the driving wheel in a penetrating mode, a flange plate is welded to the end of the inner end of the driving main shaft, and a clamping plate is installed on the driving main shaft in a sleeving mode and fixedly connected with the driving wheel and the flange plate through bolts which are distributed circumferentially in an even mode. By means of the triangular rear crawler belt assembly, rigidity and bearing capacity of the high molecular material driving wheel are effectively improved, and stability of internal materials of the high molecular material driving wheel is guaranteed; by means of a driving main shaft assembly which is of a steel integrally-welded structure, high-rigidity and high bearing capacity requirements of a low speed and heavy duty triangular crawler belt can be satisfied sufficiently, materials are saved, and production cost is lowered.

Owner:CHONGQING TECHU NEW ENERGY

Motorcycle large goods shelf checking tool

InactiveCN101013041AGuaranteed assembly efficiencyMeet the requirements of consistent productionMeasurement devicesVehicle frameEngineering

The invention discloses a motorcycle big shelves detection equipment, including the first substrate, the second substrate, the spacing baffle, the bending positioning block, the positioning pole and the positioning axis, and the first substrate and the second substrate parallel installing up and down, the two substrates dislocation in the axial direction, and the part right to them connecting through the supporting pole; the spacing baffle is vertically fixed at the tail end of the first substrate, and the left and right sides of the substrate center are symmetrically installed the bending positioning block, and the first substrate in the front of the bending positioning block has the positioning pole, the positioning pole matching the vehicle frame installation hole in the big shelf standard parts; the positioning axis is equipped in the front of the second substrate, and the rear cross axis installation hole of the big shelf standard parts can cover the positioning axis. The invention can improve the quality measurement speed and accuracy when the motorcycle enterprises having the big shelves entering the plant, to ensure the big shelf quality meeting the requirements, and effectively improving the assembly speed of the big shelves, to meet the requirements of the consistency production.

Owner:力帆科技(集团)股份有限公司

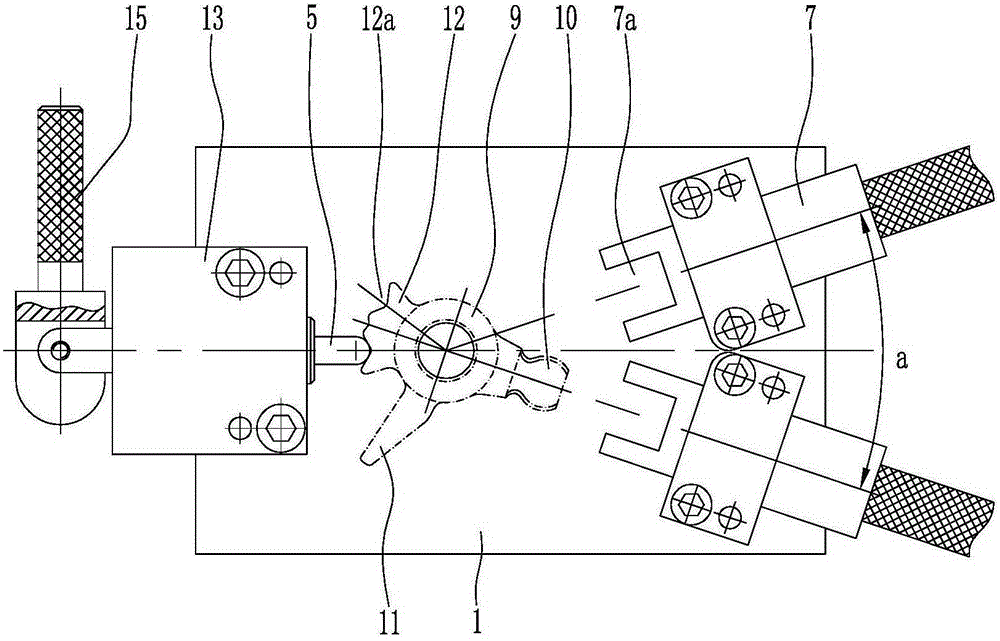

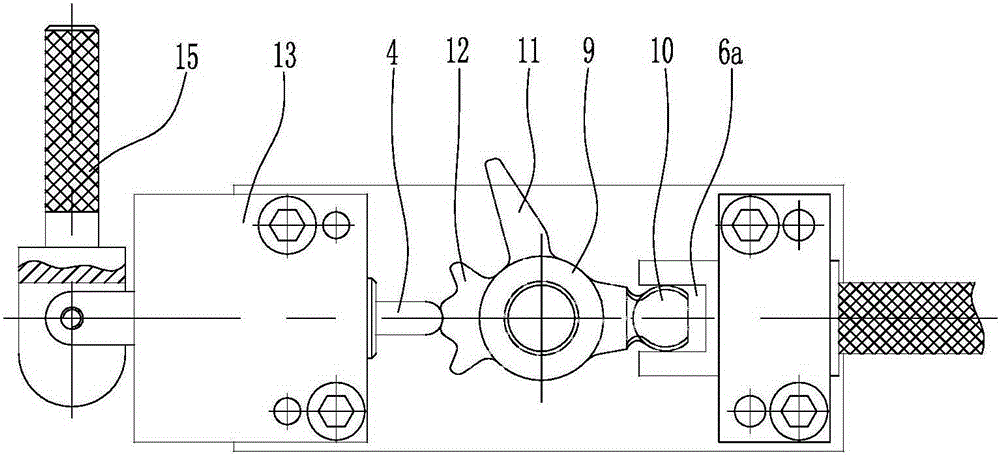

Automobile gearbox shift pendulum rod wavelike surface and ball head position detection mechanism

InactiveCN105222668ASimple structureFew partsMechanical measuring arrangementsEngineeringAutomotive transmission

The invention discloses an automobile gearbox shift pendulum rod wavelike surface and ball head position detection mechanism. A top cover is arranged on a first support block, the vertical plate of the top cover is on the left of the first support block, the left end of a positioning pin passes through the vertical plate of the top cover and is hinged to an operating handle, and the positioning pin is sleeved with a spring. A second support block is fixed on the right-end plate surface of a bottom plate, a measuring block is arranged in the second support block in a penetrating way, the measuring block is provided with a 'U'-shaped clamp slot in the left end, and the opening of the clamp slot directly faces the positioning pin. A positioning shaft is arranged between the positioning pin and the measuring block, the positioning shaft is perpendicular to the bottom plate, the lower end of the positioning shaft is fixed to the bottom plate, and an annular boss integrally formed by the lower part of the positioning shaft is supported by the bottom plate. The mechanism of the invention has the advantages of clever design, simple and compact structure, easy implementation, fewer parts, convenient assembly, and low cost. The detection operation is easy, quick and labor-saving, detection involves few working procedures, the detection result is true, accurate and reliable, and the detection efficiency is high. The mechanism can ensure that shift pendulum rods meet the requirement of production consistency.

Owner:CHONGQING YINGQUAN STANDARD PARTS

Method for detecting automobile shift swing rod bulb symmetry

InactiveCN105258625ANo circumferential rotationSmooth side to side movementMechanical measuring arrangementsEngineering

The invention discloses a method for detecting automobile shift swing rod bulb symmetry. An employed measuring tool comprises a base plate, a locating shaft, a first supporting seat, a lining, a positioning latch, a second supporting seat, a gauging spindle, a handle, etc. The method comprises the steps: 1) aligning the axle hole on a shift swing rod axle sleeve with the locating shaft, the bulb of a shift swing rod orientating to the right; 2) moving the shift swing rod downwards, and allowing the locating shaft to penetrate through the axle hole of the locating shaft, wherein the pin hole in the axle sleeve directly faces the positioning hole in the locating shaft; 3) allowing the front end of the positioning latch to penetrate through the pin hole in the axle sleeve, and the positioning hole in the locating shaft; and 4) moving the gauging spindle to the left, and determining that the symmetry of the shift swing rod bulb meets requirements if the bulb can be precisely clamped between the detection port formed between two measuring blocks. The measuring tool has the characteristics of simple and compact structure, convenient, fast and laborsaving detection operation, accurate and reliable detection result, and high detection efficiency, and can guarantee shift swing rods to meet production consistency requirements.

Owner:CHONGQING YINGQUAN STANDARD PARTS

Device for motorcycle engine test positioning

InactiveCN104476449AReduce labor intensityImprove reliabilityEngine testingWork holdersTest efficiencyAerospace engineering

Owner:CHONGQING JIANSEN POWER MACHINERY

Welding positioning mechanism for lower cover and middle cover of pneumatic type air inlet manifold

ActiveCN105458595APrevent side to side movementImprove reliabilityWelding/cutting auxillary devicesAuxillary welding devicesCouplingPush pull

The invention discloses a welding positioning mechanism for a lower cover and a middle cover of a pneumatic type air inlet manifold. Fixed bases are in a flat-bottom U shape. Sliding plates are arranged on the tops of the fixed bases. Each sliding plate is provided with an adapter coupling block. A pressing plate is fixed to the right end of the left adapter coupling block. A base plate is fixed to the left end of the right adapter coupling block. A locking block is installed on the left sliding plate. The locking block is connected with a piston rod of a push-pull air cylinder. The output end of a rotary air cylinder is connected with a lead screw. The lead screw is sleeved with a nut bed. The nut bed is fixed to the bottom of the right sliding plate. The front side and the right side of each fixed base are symmetrically provided with clamping air cylinders. Piston rods of the clamping air cylinders are connected with clamping blocks. The clamping blocks are provided with positioning grooves. Positioning blocks matched with the positioning grooves are fixed to the sliding plates. The welding positioning mechanism is ingenious in concept, novel in design, easy to implement, low in cost, flexible and rapid in operation, high in automation degree, capable of effectively improving the welding efficiency, good in positioning reliability and capable of ensuring the welding quality.

Owner:CHONGQING ANBIXIN AUTOMOBILE INTAKE SYST CO LTD

Measuring tool for symmetry of ball of shift swing rod

Owner:CHONGQING YINGQUAN STANDARD PARTS

Pneumatic holding device

ActiveCN105269210AFew partsSimple structureWelding/cutting auxillary devicesAuxillary welding devicesScrew threadPiston rod

The invention discloses a pneumatic holding device. A piston rod of a first air cylinder is connected with the lower end of a guide column. A positioning pin is installed at the top end of the guide column. A second air cylinder is installed on a guide barrel and connected with one end of a pressing arm, and a pressing head is fixed to the bottom face of the other end of the pressing arm. Mounting holes are formed in the four corners of a positioning ring, and a convex block is arranged between every two adjacent mounting holes in the circumferential direction. A connector is arranged between the guide column and the piston rod of the first air cylinder. A boss at the head of the connector is clamped into a T-shaped through slot in the lower end of the guide column. The lower end of the connector is in threaded connection with the piston rod of the first air cylinder. The pneumatic holding device is reasonable in design, easy to implement, simple and compact in structure, easy to assemble, small in size and occupied space, low in cost, convenient to control, and flexible and reliable in running. Moreover, liner pipes can be positioned accurately and stably, welding of the liner pipes is facilitated, and the welding quality is guaranteed.

Owner:JIANGSU YOUFU AUTO PARTS TECH CO LTD

Detection method for waveform surface and ball head position of shift swing rod of automobile gearbox

InactiveCN105241332ASimple structureFew partsMechanical measuring arrangementsEngineeringAutomotive transmission

The invention discloses a detection method for a waveform surface and a ball head position of a shift swing rod of an automobile gearbox. The method comprises the steps: 1) rotating a control handle so that a positioning pin moves leftwards and a spring is compressed; 2) sleeving a positioning shaft with a spindle sleeve of a shift swing rod so that the spindle sleeve is supported by an annular boss of the positioning shaft, making a waveform surface of the shift swing rod face to the left, and making a ball head face to the right; 3) loosening the control handle and enabling the positioning pin to move rightwards under the resilience of the spring till the right end of the positioning pin is pressed against a middle groove in the waveform surface; and 4) enabling the positioning pin to stay in a pressed state without moving by means of the elastic force of the spring, operating a measuring block and making the block move leftwards, and verifying that the waveform surface and the ball head position of the shift swing rod accord with requirements if a clamping groove in the left end of the measuring block can just clamp the ball head. The detection method is easy, fast and labor-saving to operate, has fewer detection procedures, provides a true, accurate and reliable detection result, is high in detection efficiency, and ensures that the shift swing rod satisfies the requirement of production consistency.

Owner:CHONGQING YINGQUAN STANDARD PARTS

Pneumatic double-cylinder liner positioning mechanism for automobile welding fixture

ActiveCN105269235BNo shakingGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelEngineering

Owner:JIANGSU YOUFU AUTO PARTS TECH CO LTD

Method of detecting ball groove of waveform surface of shift swing rod

InactiveCN105241331ASimple structureFew partsMechanical measuring arrangementsElectrical and Electronics engineeringEngineering

Owner:CHONGQING YINGQUAN STANDARD PARTS

Welding fork for stand pipe of motorcycle

InactiveCN101966637BSuitable for mass productionPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPositioning system

Owner:力帆科技(集团)股份有限公司

A rear axle assembly welding tool liner clamping mechanism

ActiveCN105382457BNo shakingGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSteel plates

The invention discloses a liner tube clamping mechanism for a rear axle assembly welding tool. A piston rod of a first air cylinder is connected with the lower end of a guide pillar. A locating pin is installed at the top end of the guide pillar. A second air cylinder is arranged on a guide cylinder. A piston rod of the second air cylinder is connected with one end of a pressing arm. A pressing head is fixed to the bottom face of the other end of the pressing arm. A big-end-up two-section type step hole is formed in the center of the locating pin. A long countersunk screw is arranged in the step hole in a penetrating manner. A connector is arranged between the guide pillar and the piston rod of the first air cylinder. A boss of the head of the connector is clamped in a T-shaped through groove in the lower end of the guide pillar. The lower end of the connector is in threaded connection with the piston rod of the first air cylinder. A connecting plate is arranged between the guide cylinder and the second air cylinder. The connecting plate is formed by stamping a steel plate and is provided with a first plate body and a second plate body, wherein an obtuse angle is formed between the first plate body and the second plate body. According to the liner tube clamping mechanism, control is convenient, operation is flexible and reliable, accuracy and stability of liner tube locating can be achieved, the welding quality is guaranteed, and the requirement for consistent production can be met.

Owner:重庆优茨巴汽车部件有限公司

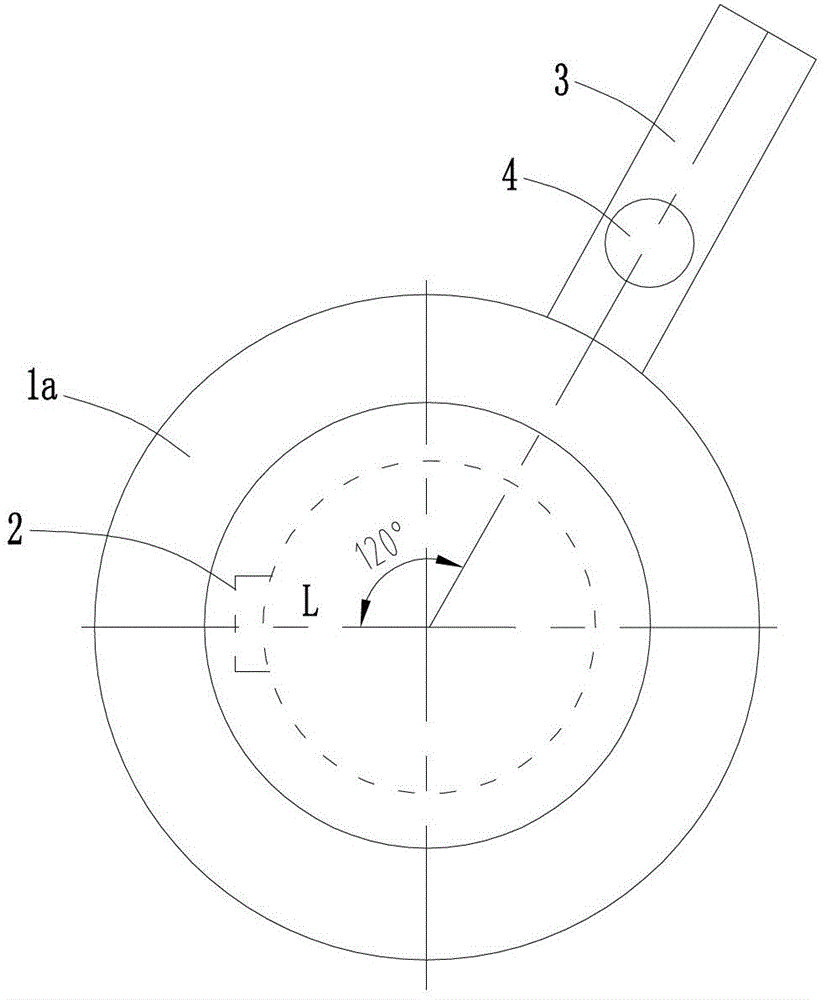

Detection device for breather pipe of breather valve of oil tank

InactiveCN102661694BEasy to processFirmly connectedMechanical measuring arrangementsBreatherEngineering

The invention discloses a detection device for a breather pipe of a breather valve of an oil tank. An annular boss (1a) is arranged in the middle of a positioning column (1); a limiting arm (3) is fixed on the circumferential surface of the annular boss (1a) and is perpendicular to the circumferential surface of the annular boss (1a); a limiting hole (4) is formed at a position of the limiting arm (3) close to the annular boss (1a); a limiting block (2) is arranged below the annular boss (1a) and is tightly pressed against the cylindrical surface of the positioning column (1) and the bottom surface of the annular boss (1a); and an angle of 120 degrees is formed between the limiting block (2) and the limiting arm (3) on the circumference. By the device, the quality detection speed and accuracy of a motorcycle enterprise can be greatly improved when the oil tank is transferred into a factory, the position of the breather pipe of the breather valve on the oil tank meets the requirement, the defect caused by positional deviation of the breather pipe of the breather valve is effectively overcome, and the requirement for production compliance is met.

Owner:力帆科技(集团)股份有限公司

Clamping tool for motorcycle frame printing

InactiveCN104608072AHigh clamping accuracyGood stabilityWork holdersOther printing apparatusVehicle framePiston rod

The invention discloses a clamping tool for motorcycle frame printing. A front positioning plate (2) is arranged at the front end of a base plate (1). A first positioning column (3) is fixed to the front positioning plate (2). A rear positioning plate (4) is arranged behind the front positioning plate (2), installed on the base plate (1) and provided with a second positioning column (5) in a penetrated mode. The second positioning column (5) and the first positioning column (3) are located on the same horizontal straight line. The rear end of the second positioning column (5) is connected with a piston rod of an air cylinder (6). The air cylinder (6) is installed on the top of a support (7). The bottom end of the support (7) is fixed to the surface of the rear end of the base plate (1). According to the clamping tool, a motorcycle head pipe of a motorcycle frame is positioned in the manner of pneumatic clamping, and the clamping stability is high; the clamping tool is easy and convenient to operate, saves time and labor, effectively improves marking efficiency and meanwhile satisfies the requirement of uniform production.

Owner:力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com