Pneumatic device for welding and positioning of intake manifold lower cover and middle cover

A technology for welding positioning and intake manifold, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc. Consistent production, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

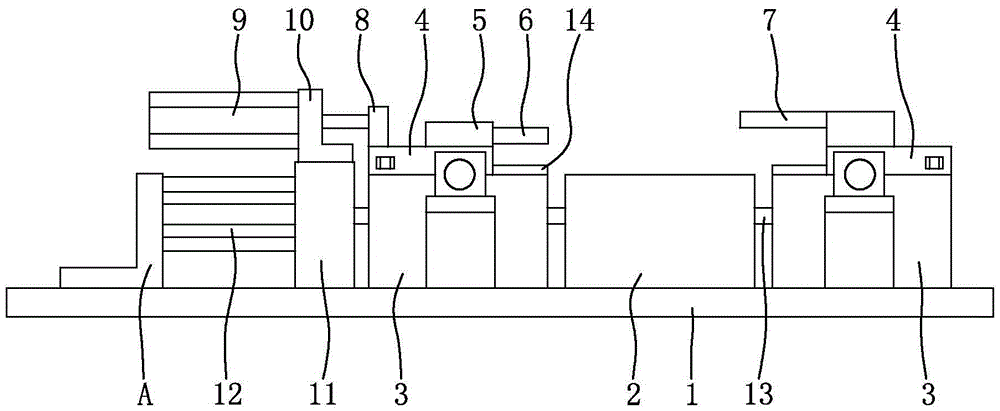

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0013] Such as figure 1 As shown, the bottom plate 1 is a rectangular steel flat plate structure, and the mold base 2 is installed on the base plate 1. The bottom of the mold base 2 is fixed to the base plate 1, and the shape of the top of the mold base 2 is adapted to the lower cover of the intake manifold. The left and right sides of mold base 2 are provided with fixed seat 3 symmetrically, and fixed seat 3 is flat-bottomed " U " shape, and the bottom surface of fixed seat 3 is supported on the base plate 1, and fixed seat 3 is fixedly connected together with base plate 1 by bolt. Two mutually parallel guide rails 14 are installed on the top of each fixed seat 3, and the fixed seat 3 is supported with a slide plate 4, and the slide plate 4 slides with the guide rail 14 at the top of the corresponding fixed seat 3 through the chute at its bottom.

[0014] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com