Method of detecting ball groove of waveform surface of shift swing rod

A technology of corrugated surface and surface ball, which is applied in the field of detecting the ball groove of the corrugated surface of the shift lever, which can solve the problems of affecting the assembly accuracy of the shift lever, difficulty in meeting consistent production, and lax product quality control, etc., and achieves a simple structure , less detection process, fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

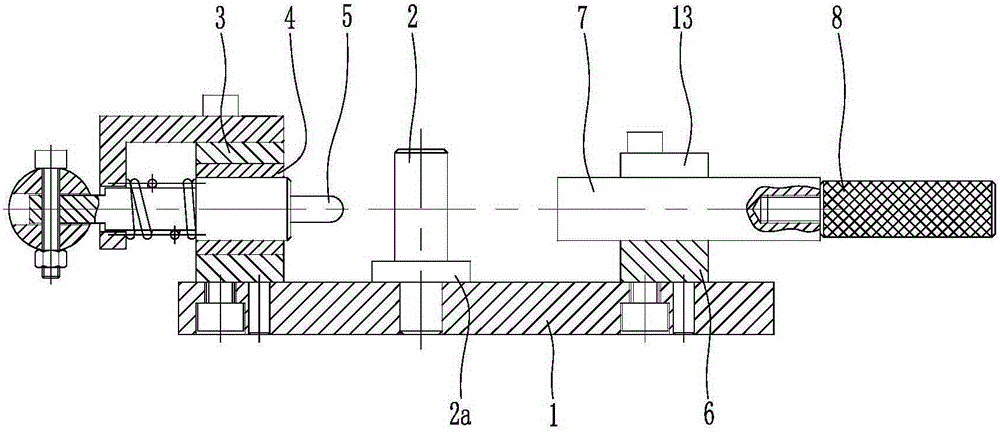

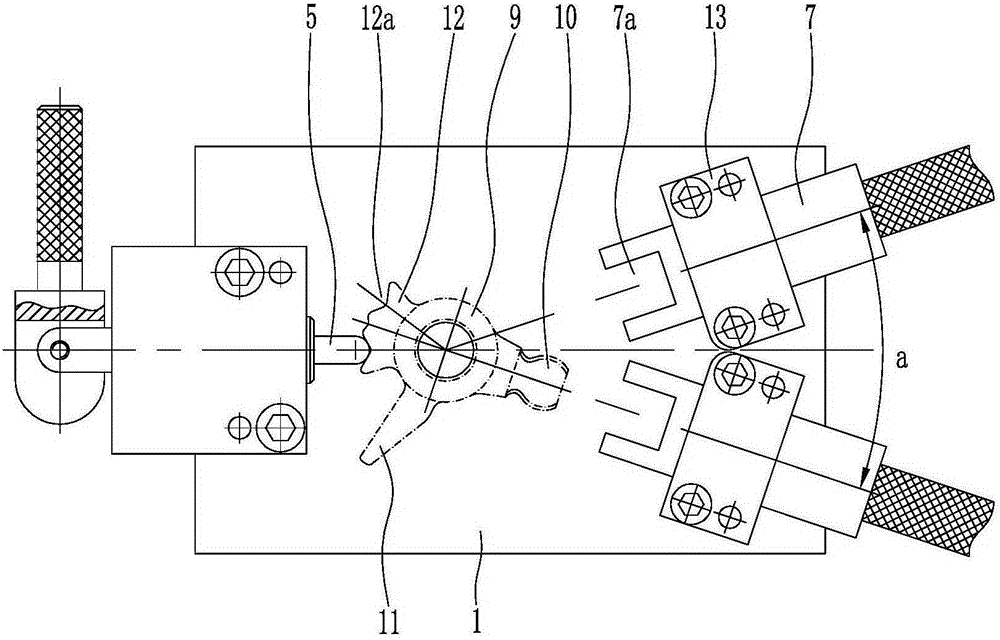

[0019] like figure 1 , figure 2 As shown, the measuring tool used in the present invention is composed of a base plate 1, a positioning shaft 2, a first support block 3, a bushing 4, a positioning pin 5, a second support block 6, a gauge block 7, a handle 8 and a cover plate 13 and the like. Wherein, the bottom plate 1 is a rectangular flat plate structure, and a positioning shaft 2 is arranged in the middle of the bottom plate 1. The positioning shaft 2 is perpendicular to the bottom plate 1. The top surface of the positioning shaft 2 and the circumferential surface are transitioned through a tapered surface, and the lower end of the positioning shaft 2 extends Inserted into the bottom plate 1, the two are closely matched, and the annular boss 2a integrally formed on the lower part of the positioning shaft 2 is supported by the bottom plate 1.

[0020] li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com