Motorcycle direction column check tool

A technology for motorcycles and inspection tools, applied in the field of tooling and fixtures, can solve the problems of poor accuracy, inability to achieve consistent production, and difficult detection, and achieve the effects of improving speed and accuracy, ensuring assembly efficiency, and reasonable design.

Inactive Publication Date: 2010-02-10

力帆科技(集团)股份有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, when receiving the steering column from the supporting manufacturer, all motorcycle companies rely on the experience of the workers to check the overall space size of the steering column, and whether the position and diameter of each installation hole meet the requirements. Not only is the detection difficult, but Moreover, the accuracy is poor, and it is easy to cause the quality control of the incoming factory to be lax.

If there is a size deviation in the assembly part on the steering column, it will cause the steering column to be unable to connect with its peripheral parts, causing unnecessary troubles such as rework and return; even if some steering columns can be installed by modifying the size of the installation part, it is bound Will affect the efficiency of assembly, and can not meet the requirements of consistent production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

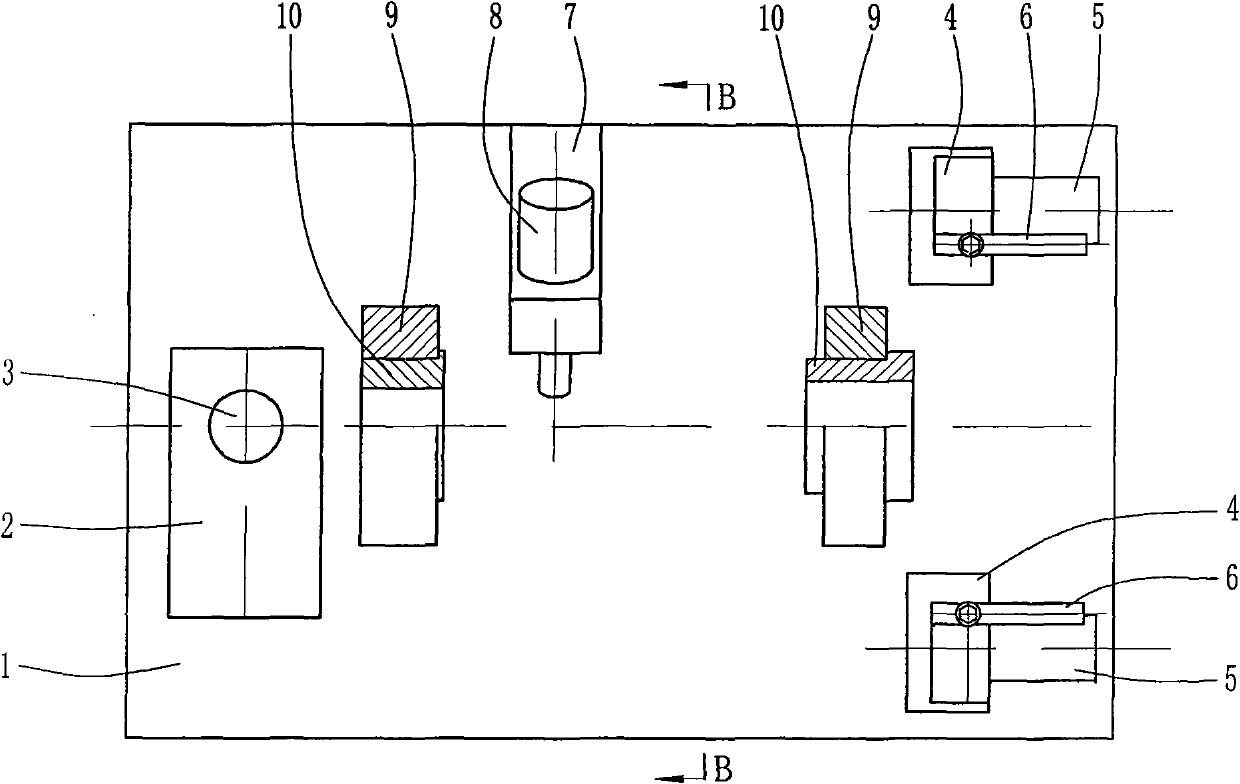

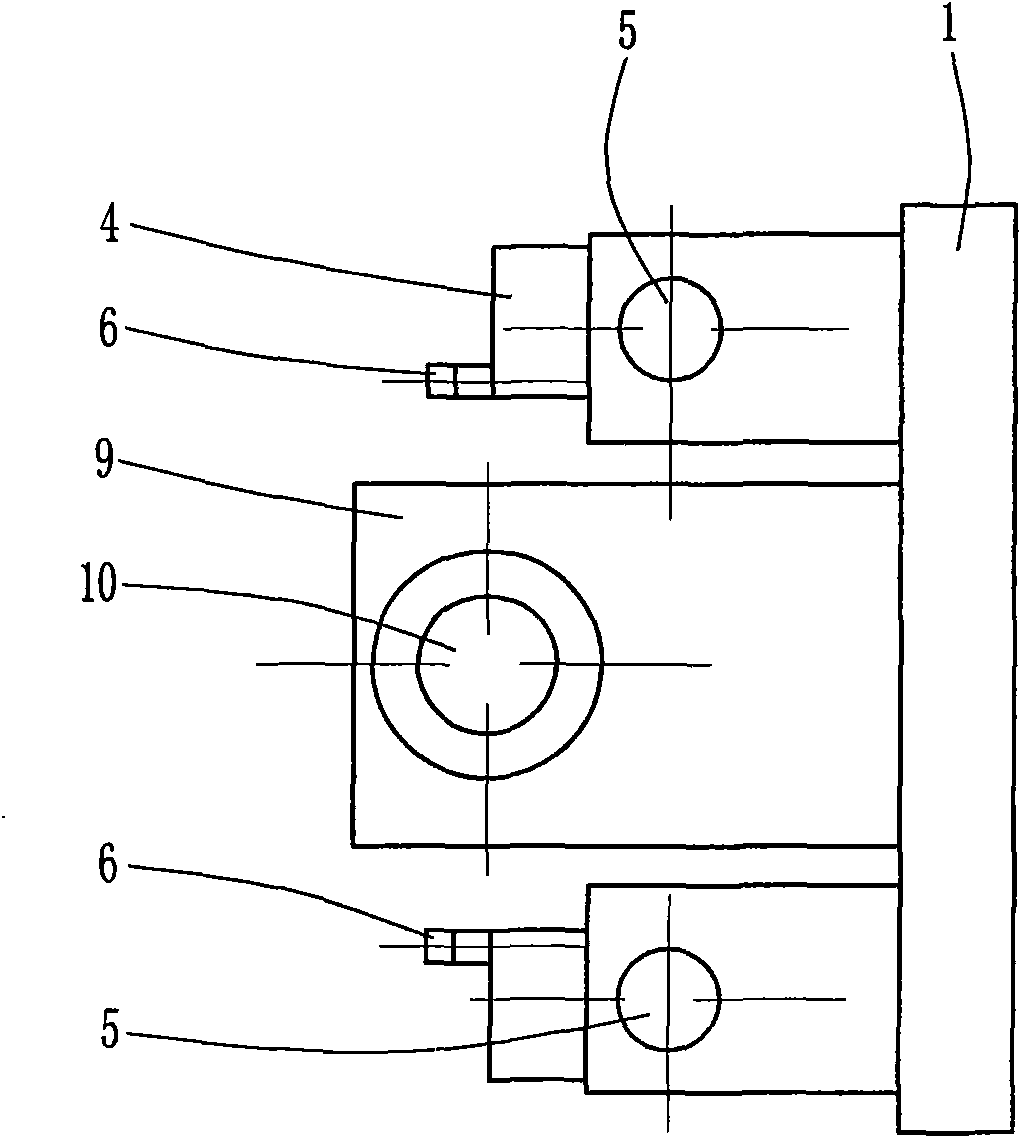

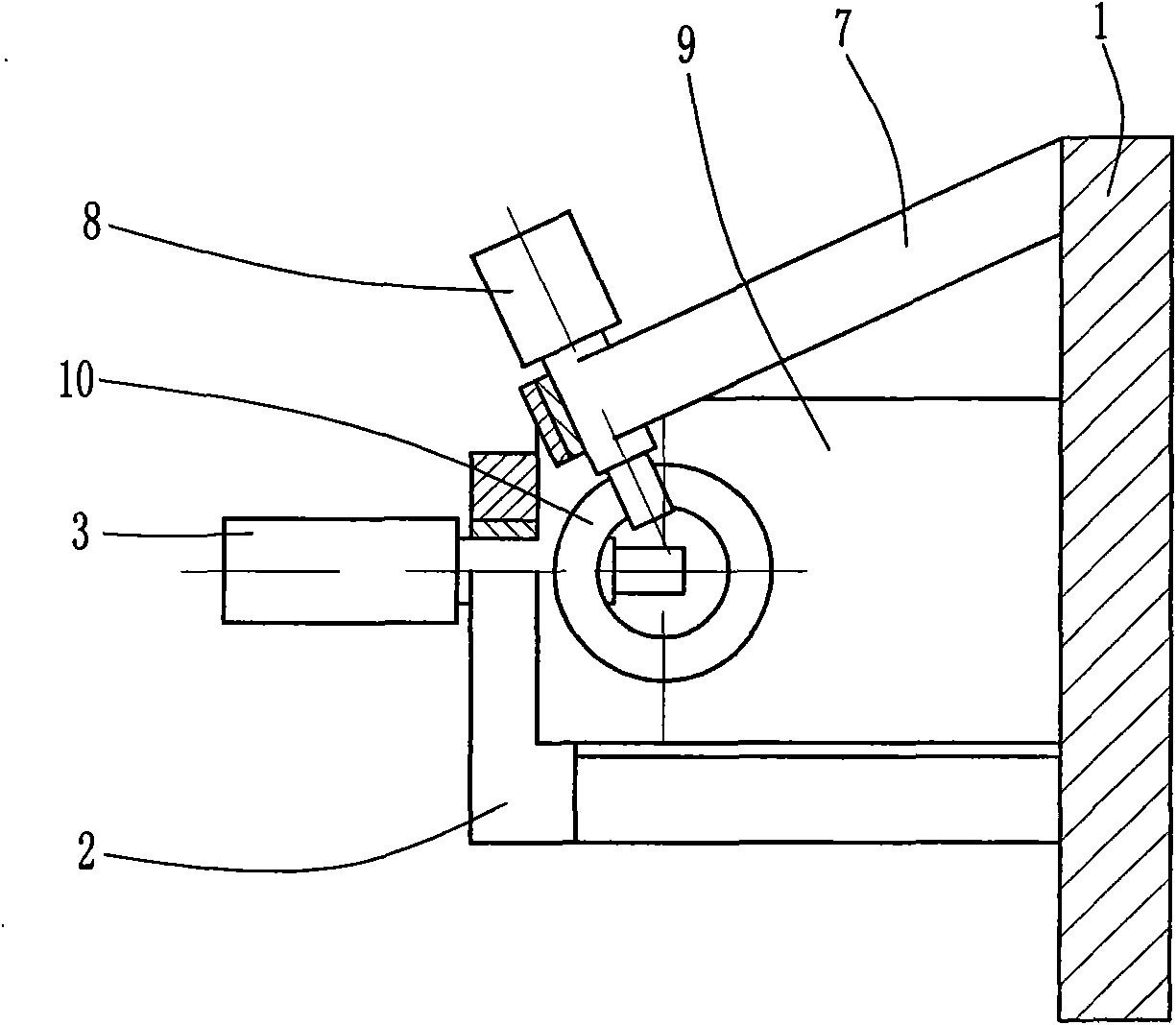

The invention relates to a motorcycle direction column check tool. A right angle shape support plate is arranged on the board at the left end of a bottom board, the vertical bottom section of the support plate is fixed with the bottom board, a first location pin is arranged at the horizontal board section of the support plate in penetrating way from up to down; the opposite sides of the front andrear parts of the board at the right end of the bottom board are provided with a first support, the right end face of each first support is fixed with a location column, and the top of the first support is provided with a 'right angle' shape location support; the middle part of the board at the rear end of the bottom board is provided with a location strip, the bottom of the location strip is fixed with the bottom board, the front end of the location strip inclines forward, and the front part of the location strip is provided with a second location pin in penetrating way from back to front; and the left and right sides of the second location pin are all provided with a second support, each second support is provided with a shaft sleeve, and the axes of the two shaft sleeves are collinear.The invention can greatly improve speed and accuracy of quality detection when direction columns are transported to motorcycle enterprise, the quality of the direction column is ensured to meet requirement, speed in direction column assembly is effectively improved, and requirement of consistent production is met.

Description

technical field The invention belongs to the technical field of fixtures, and in particular relates to a detection device for a steering column of a motorcycle. Background technique The steering column is an important part of the steering system of a motorcycle. It is generally composed of a column body and an upper connecting plate. The upper end and the middle and lower parts of the column body are supported on the frame by bearings. There is a steering tube installation hole at the lower end of the column body. , for the installation of the steering handle tube, and the middle part of the cylinder has a mounting hole connected with the steering lock. The upper link plate is set on the top of the column, and the front shock absorber installation holes are opened at the left and right ends of the upper link plate, so as to be connected with the upper end of the corresponding front shock absorber, and each front shock absorber installation hole is set next to There are deco...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B5/00G01B5/12

Inventor 刘润萍朱德君

Owner 力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com