Front and back clamping mechanism for welding mounting bracket assembly of automobile steering column

An automobile steering column and mounting bracket technology, applied in the field of tooling fixtures, can solve the problems of difficulty in ensuring the accuracy of the position of the steering wheel angle mounting bracket, cumbersome operation, difficult alignment, etc., and achieve the effects of ensuring accuracy, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

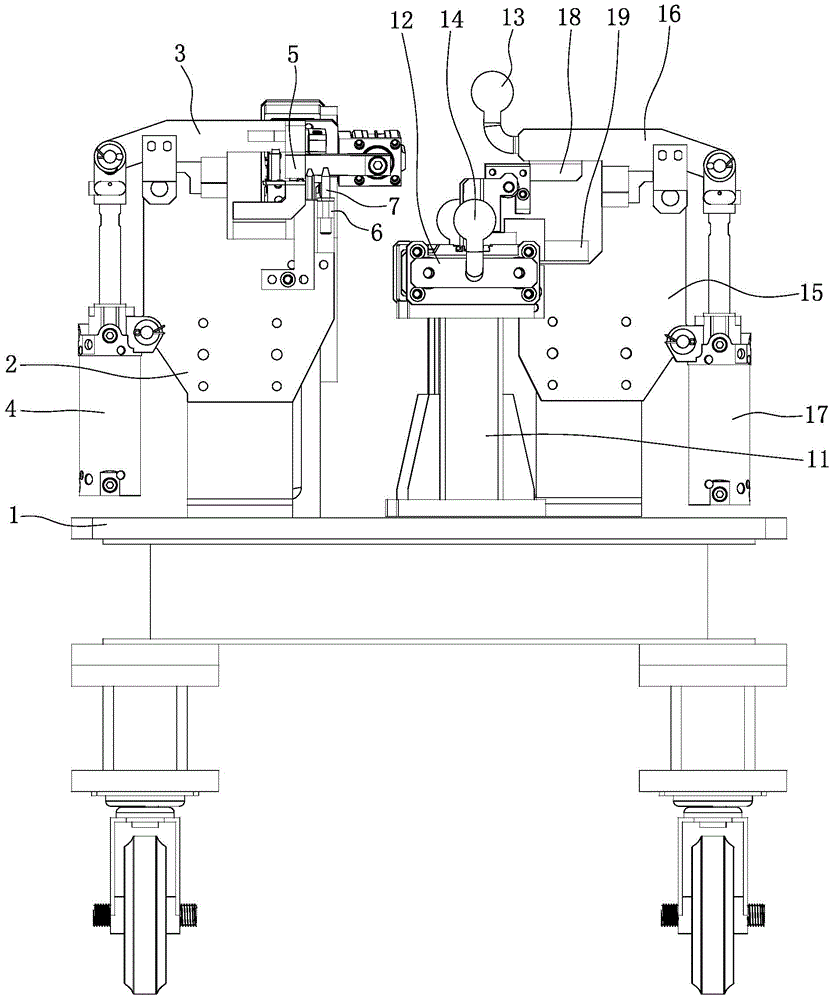

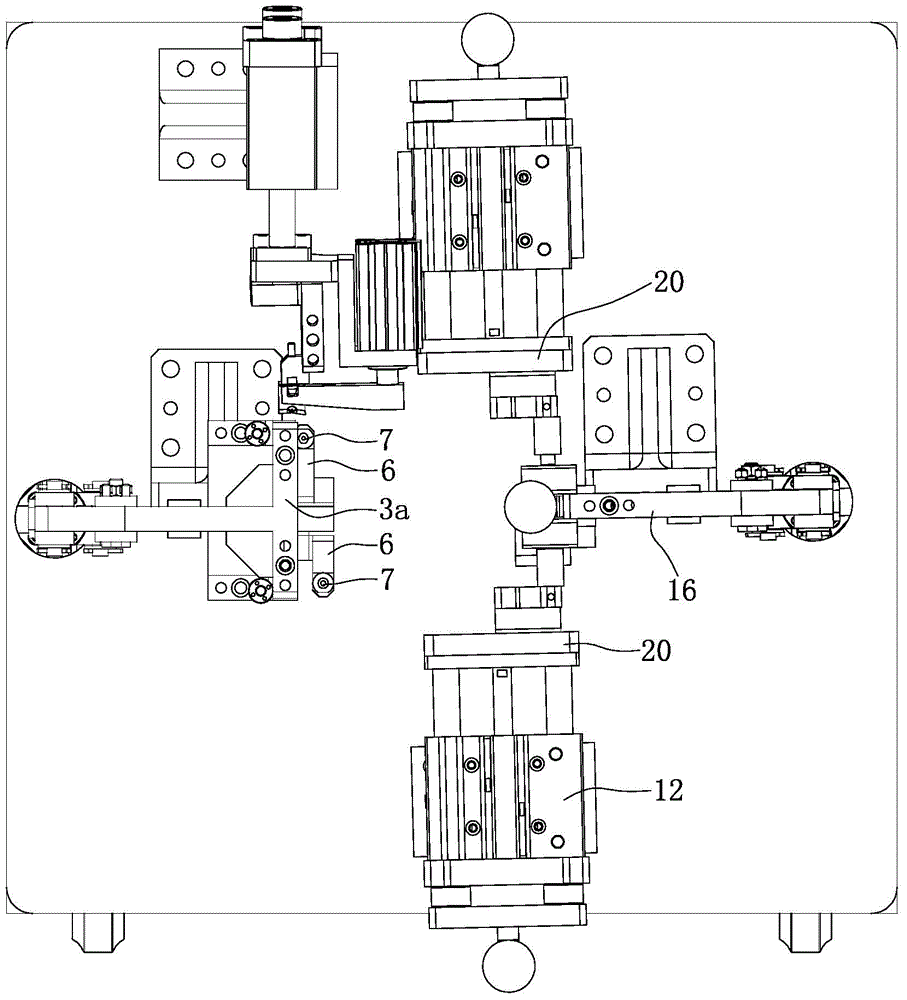

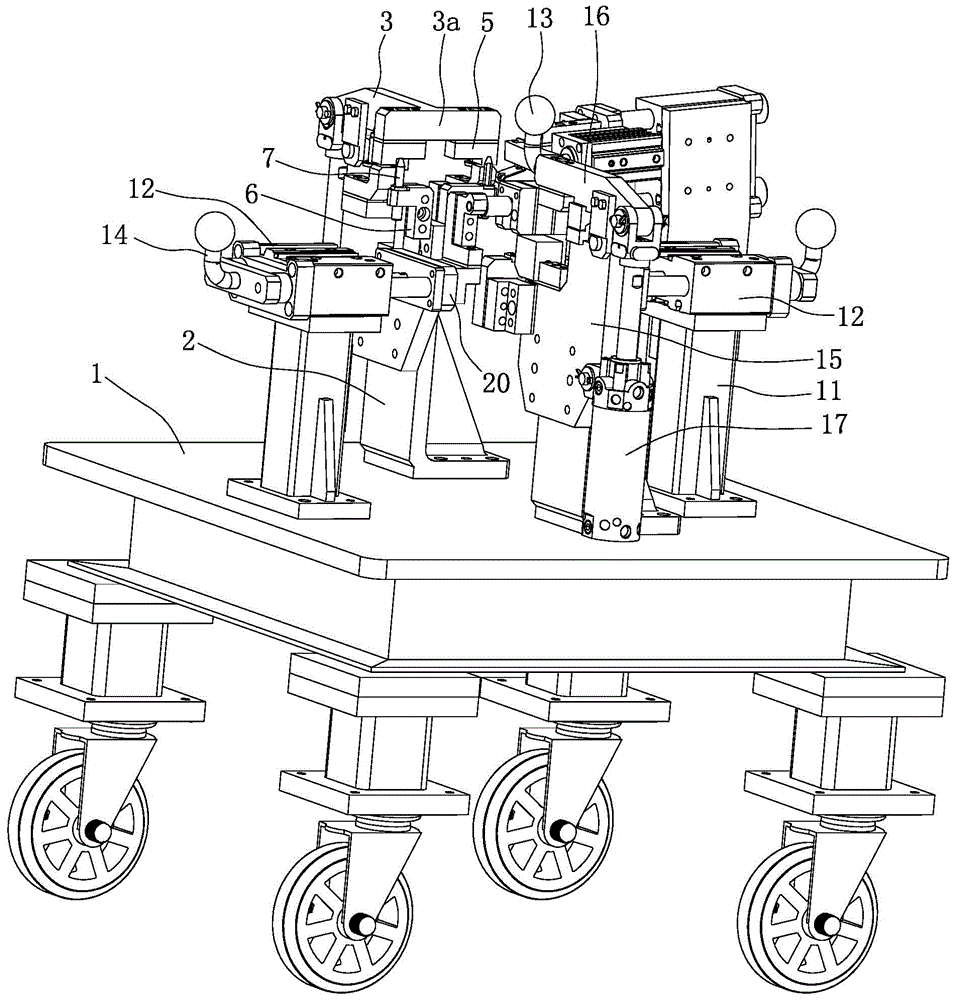

[0016] Such as figure 1 , figure 2 , image 3 As shown, the base plate 1 is rectangular, and a head support 2 is arranged in the middle of the front end of the upper plate surface of the base plate 1. The bottom end of the head support 2 is fixed to the base plate 1, and the front swing arm is hinged on the top of the head support 2. 3. The front end of the front swing arm 3 is hinged to the piston rod of the front clamping cylinder 4, the cylinder body of the front clamping cylinder 4 is fixed to the head support 2, and the axis line of the front clamping cylinder 4 is perpendicular to the bottom plate 1. The rear end of the front swing arm 3 is integrally formed with a bar 3a, and the bar 3a extends along the left-right direction, and the left and right ends of the bottom of the bar 3a are symmetrically provided with front pressing blocks 5, and each fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com