Check tool for front fender

A front fender and inspection tool technology, which is applied in the field of tooling and fixtures, can solve the problems of inaccurate grasp of the quality of the front fender, unguaranteed use performance and decorative effect, rework and rework, etc., so as to improve the quality inspection. speed and accuracy, guaranteeing performance and decorative effect, and the effect of accurate control of incoming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

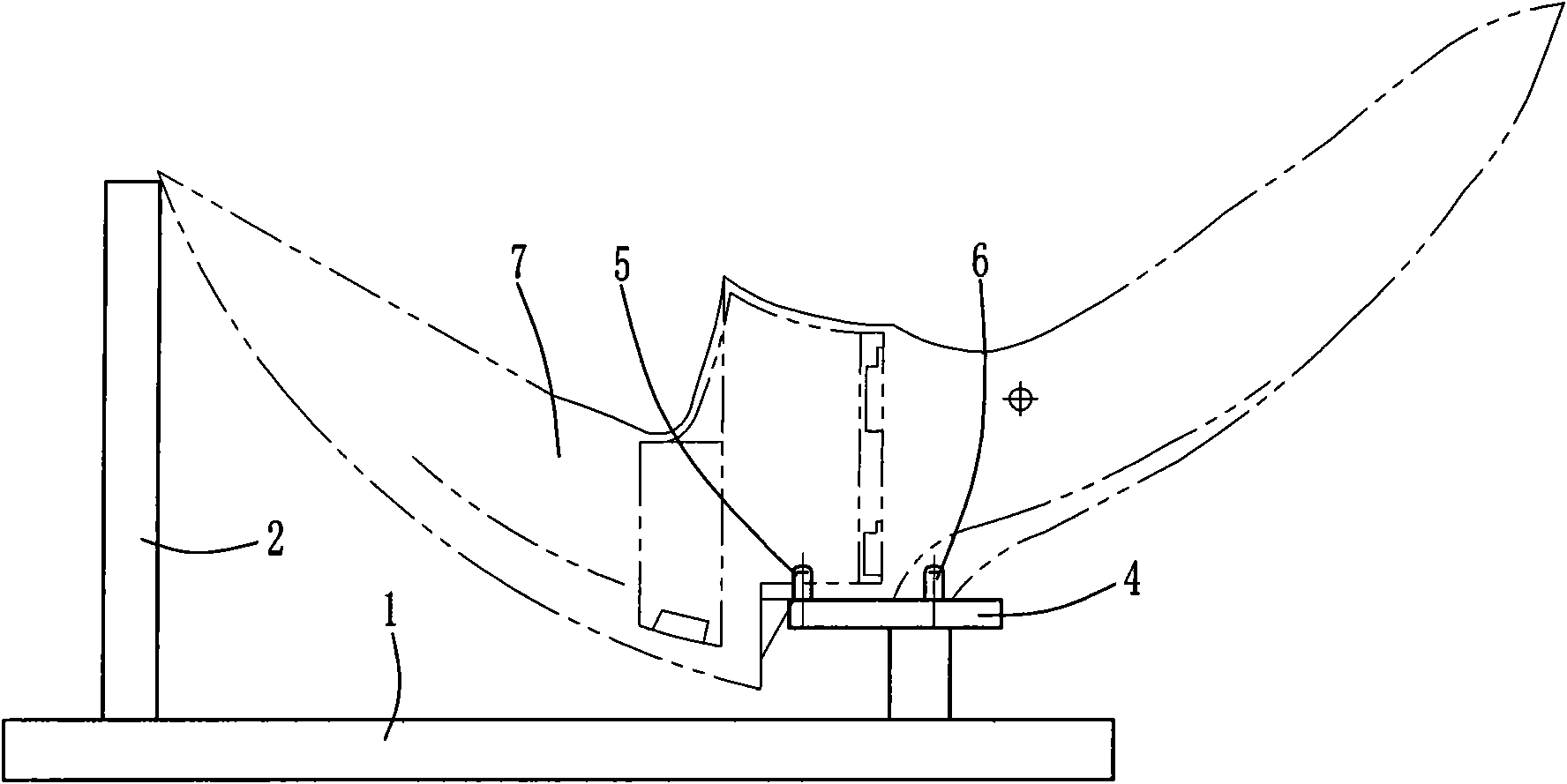

[0015] The present invention will be further explained below in conjunction with the drawings and embodiments:

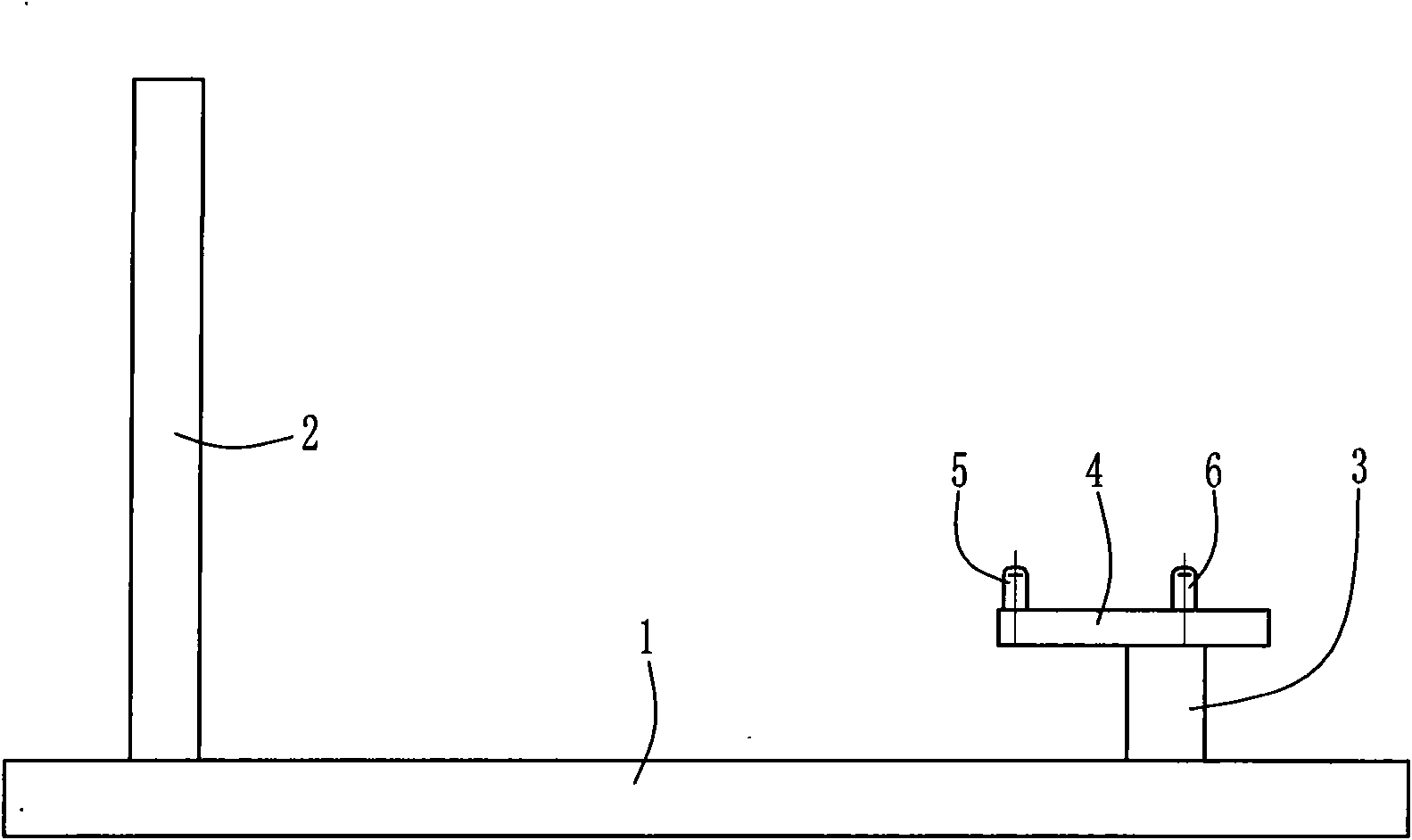

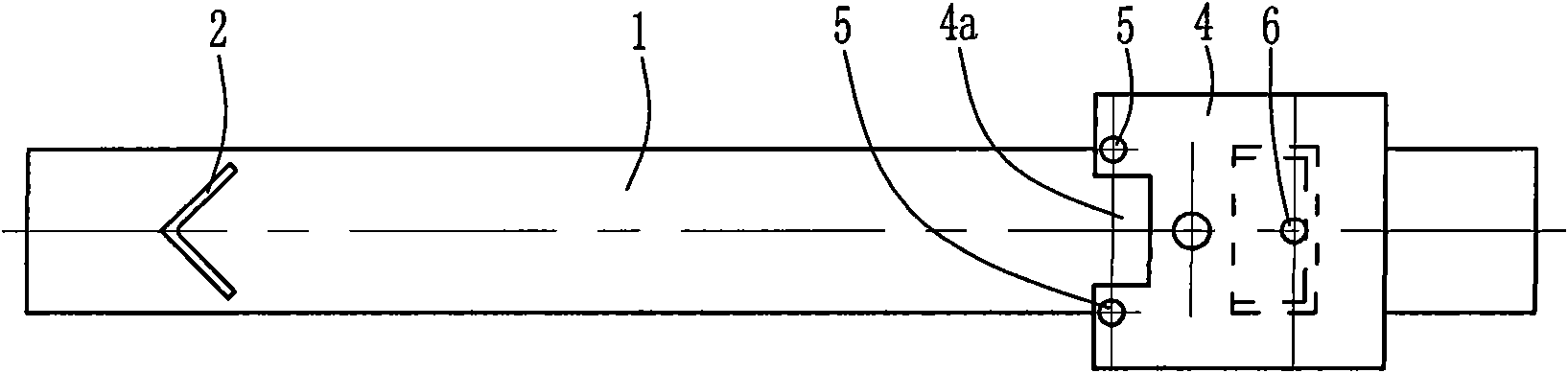

[0016] Such as figure 1 , figure 2 As shown, the present invention is composed of a base 1, a limiting pile 2, a pillar 3, a positioning plate 4, a front positioning pillar 5, and a rear positioning pillar 6, and the base 1 is a rectangular parallelepiped structure with a length significantly greater than the width and height. The rear end of the top surface is welded with a pillar 3 which is perpendicular to the base 1 and the top of the pillar 3 is welded to the bottom surface of the positioning plate 4. The positioning plate 4 is a rectangular flat plate structure. Two front positioning columns 5 are welded side by side at the front end of the upper surface of the positioning plate 4. The top surface of the front positioning column 5 is a spherical surface; the rear part of the upper surface of the positioning plate 4 is welded There is a rear positioning column 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com