Detecting device of motorcycle rear fork welding assembly

A combined detection and motorcycle technology, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve problems such as poor accuracy, lax quality control at the factory, and inability to achieve consistent production, to improve speed and efficiency. Accuracy, consistent production, easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

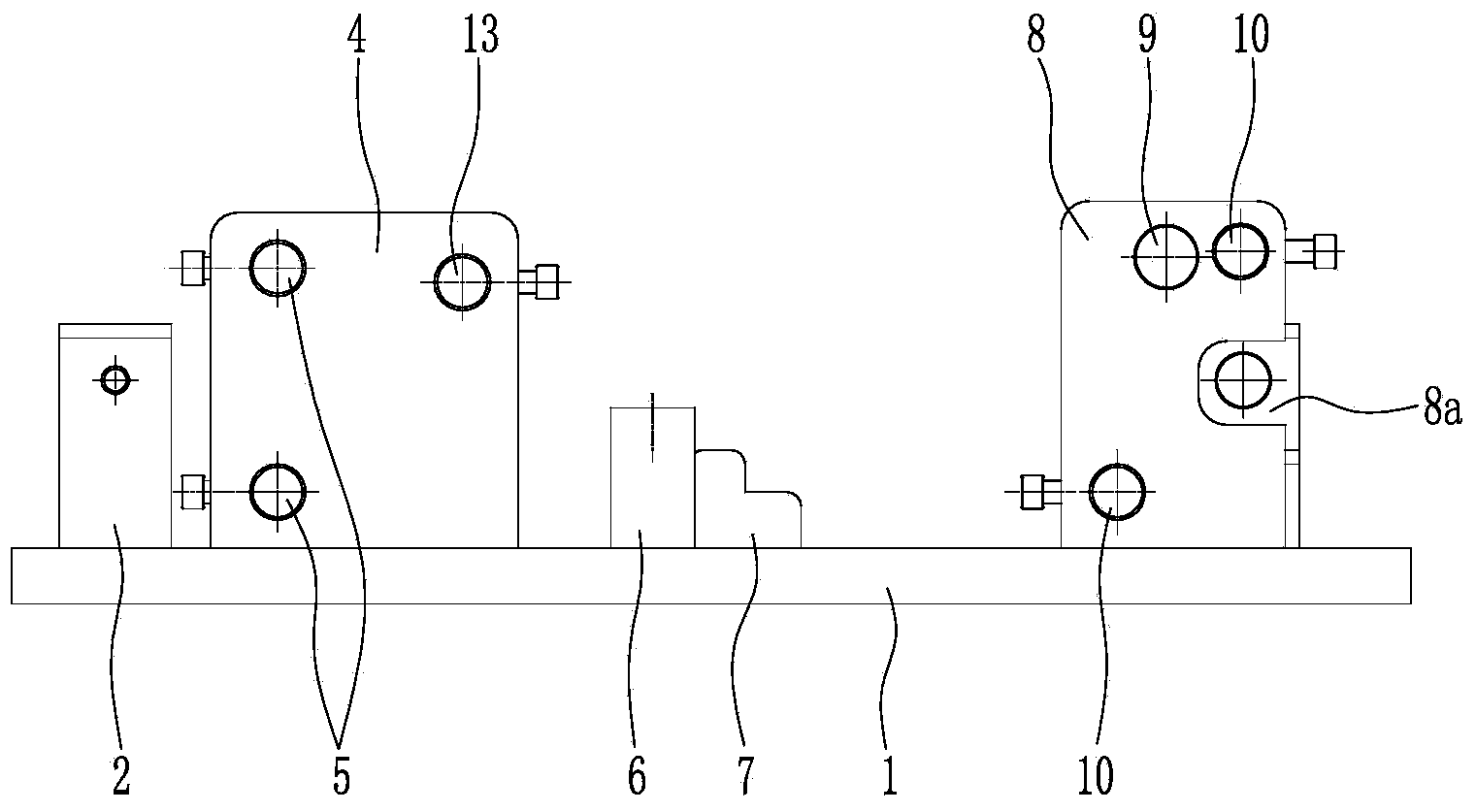

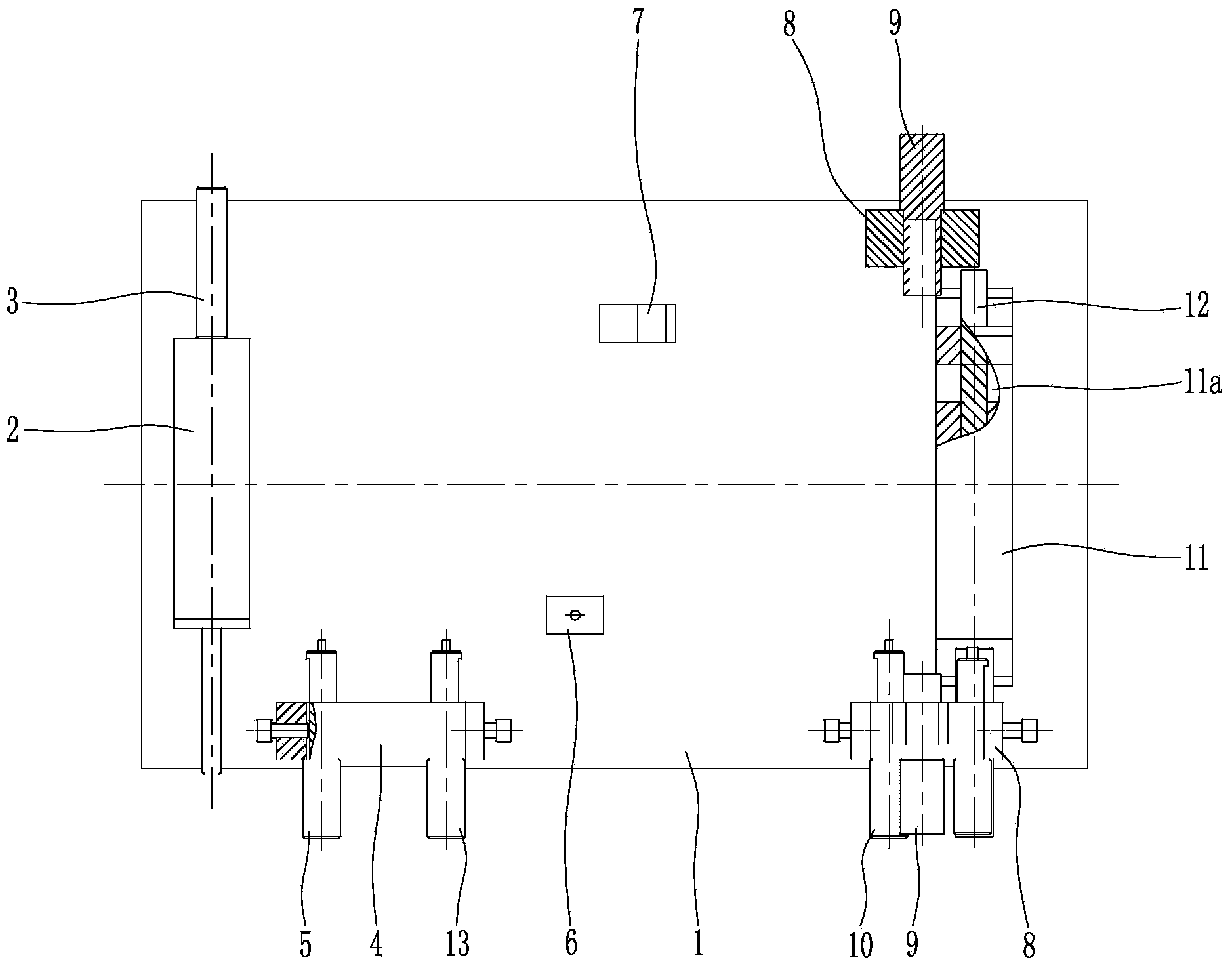

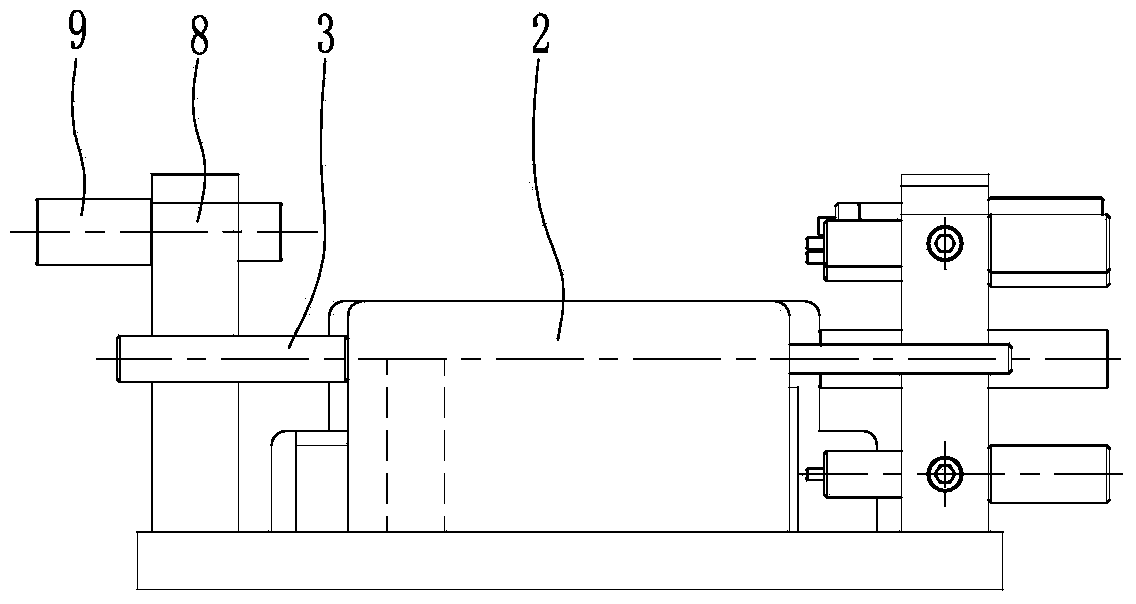

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0029] like figure 1 , figure 2 , image 3 As shown, the base 1 is a rectangular flat plate structure, and the rear fork bush positioning seat 2 is fixed in the center of the front end of the upper plate surface of the base 1. The rear fork bush positioning seat 2 is a rectangular parallelepiped structure, and the left and right sides of the rear fork bush positioning seat 2 Used to detect the inward opening of the rear fork bushing. On the upper part of the rear fork bushing positioning seat 2, a rear fork bushing center hole detection pin 3 is pierced from right to left, and the rear fork bushing center hole detection pin 3 is parallel to the base 1 .

[0030] like figure 1 , figure 2 , image 3 As shown, on the left side of the upper panel front of the base 1, the fixed chain box is installed with a lug positioning seat 4. The chain box is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com