Single-chain driven rear caterpillar track assembly

A single chain and assembly technology, applied in tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as poor verticality of nut threads and nut end faces, poor locking effect, difficult assembly and debugging, etc., to achieve guaranteed Position and size accuracy, structural strength and stability are good, and welding accuracy is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

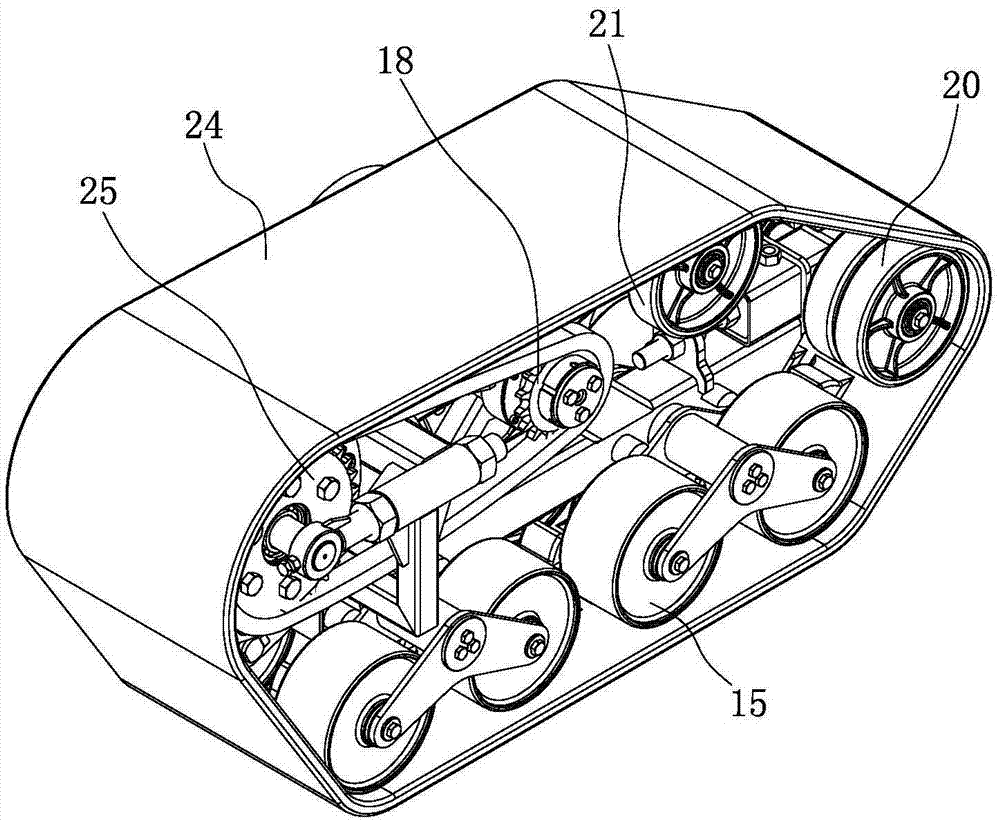

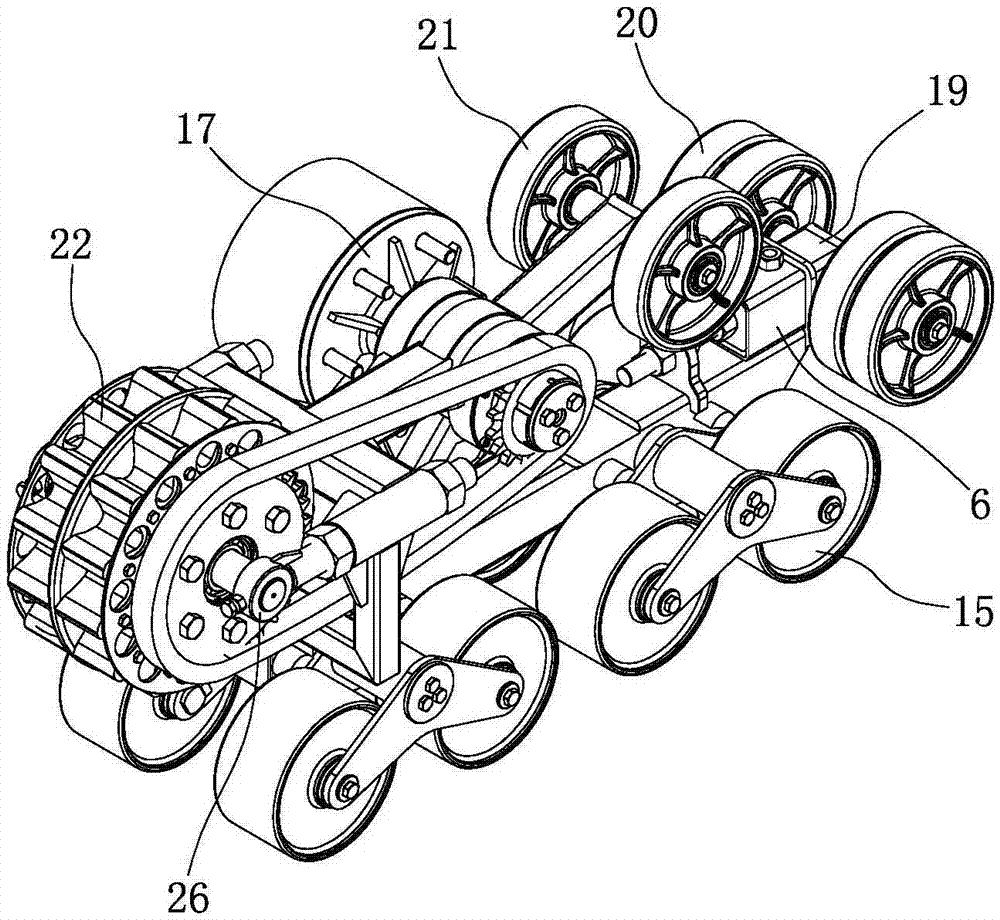

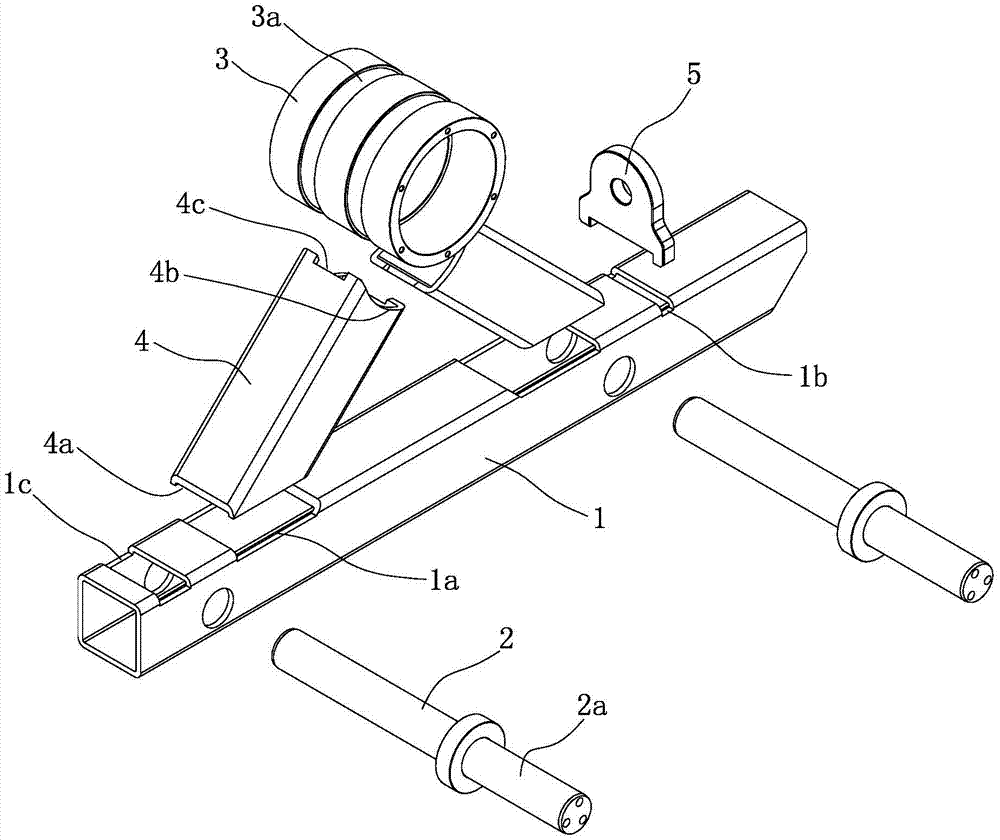

[0046] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0047] like Figure 1 to Figure 8 As shown, the skeleton of the present invention consists of a longitudinal beam 1, a free wheel shaft 2, a bearing chamber 3, an oblique support beam 4, a locking block 5, a slide rail hoop 6, a supporting wheel shaft 7, a supporting wheel branch pipe 8, and a lower beam of the driving wheel bracket 9. The upper beam 10 of the driving wheel bracket, the tensioning sliding sleeve 11, the vertical support beam 12 and the longitudinal beam 13 of the driving wheel bracket are constituted. The longitudinal beam 1 is a square tube, the front and rear ends of the longitudinal beam 1 are sealed by a sealing plate, and the sealing plate and the longitudinal beam 1 are welded and fixed. The front and rear ends of the longitudinal beam 1 are provided with free wheel shafts 2 in the transverse direction. The free wheel shafts 2 are per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com