Three-point measurement method for negative clearance of third-generation hub bearing unit

A three-point measurement and hub bearing technology, applied in the field of bearings, can solve problems such as the difficulty of directly measuring the negative clearance value of the third-generation hub bearing unit, and achieve the effects of fast measurement speed, accurate measurement results and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

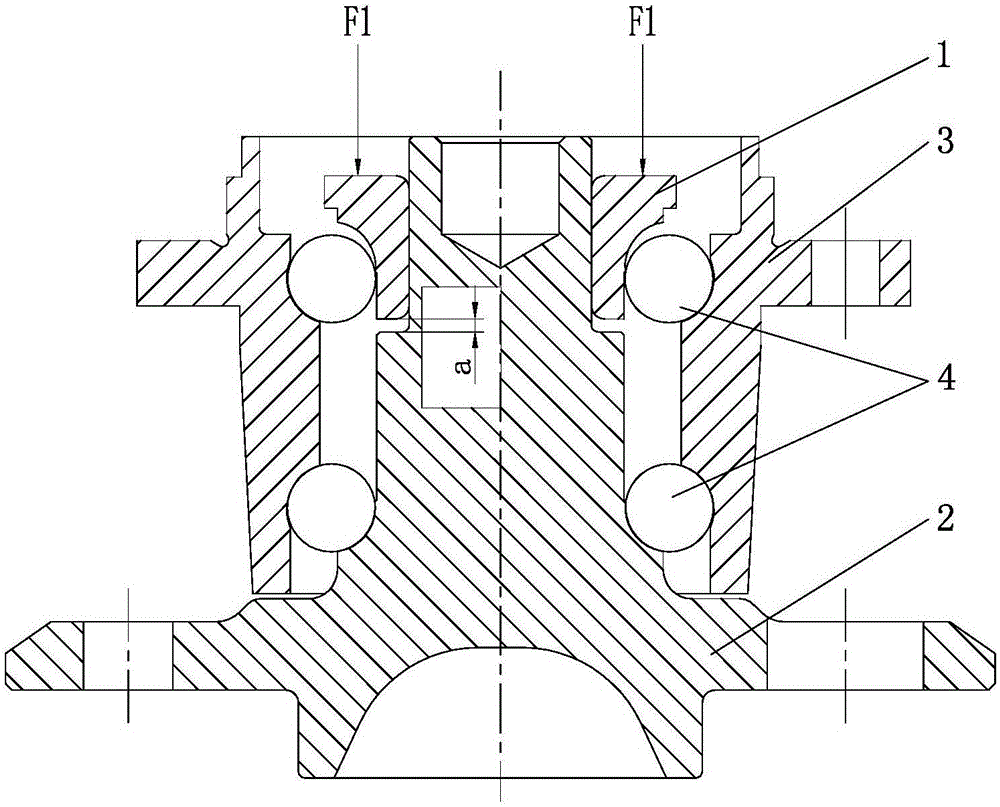

[0018] Such as figure 1 , figure 2 As shown, after the components of the above-mentioned third-generation hub bearing unit are prepared, the negative clearance measurement method includes the following steps:

[0019] 1) First assemble the first inner ring 1, the second inner ring 2, the outer ring 3, the steel ball 4 and the cage together.

[0020] 2) Next, put the small end of the first inner ring 1 downward on the shaft at the upper end of the second inner ring 2, press the second inner ring 2 to fix it, and apply a downward force on the large end of the first inner ring 1. The pressure F1 is preloaded so that the small end surface of the first inner ring 1 and the shoulder of the second inner ring 2 maintain a distance a, and the value of a is 0.1-0.15mm.

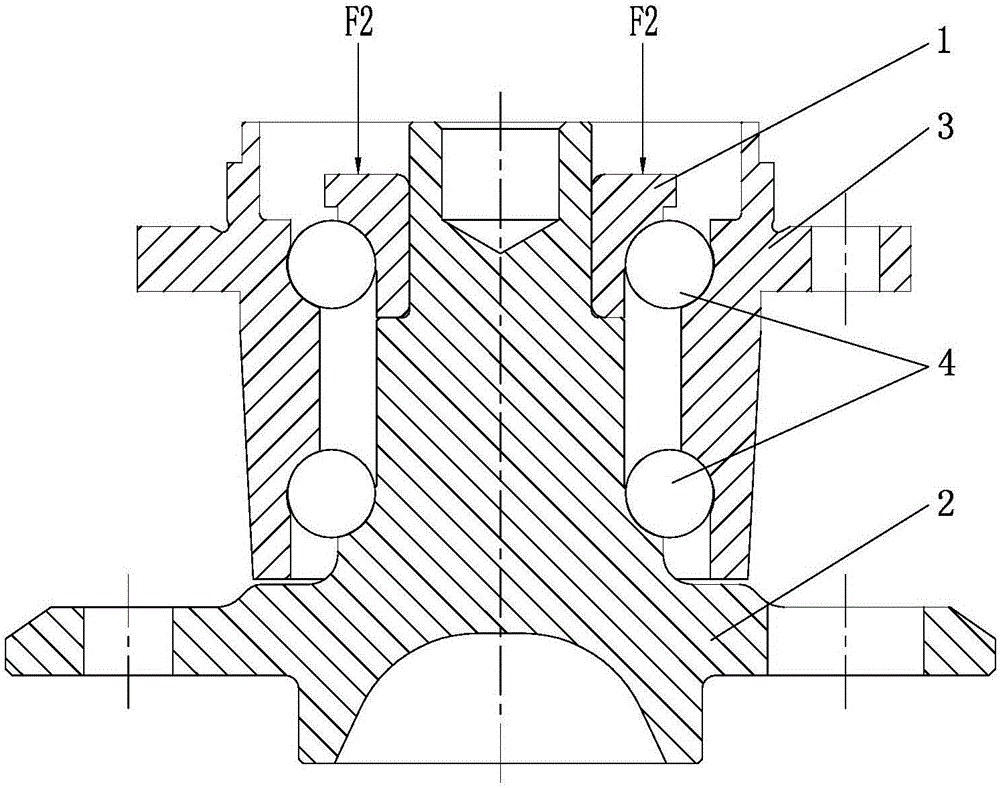

[0021] 3) Sequentially apply force to the upper and lower ends of the flange of the outer ring 3, so that the outer ring 3 can move up and down along the axial direction, install a displacement measuring instrument o...

Embodiment 2

[0026] Such as figure 1 , figure 2 As shown, after the components of the above-mentioned third-generation hub bearing unit are prepared, the negative clearance measurement method includes the following steps:

[0027] 1) First assemble the first inner ring 1, the second inner ring 2, the outer ring 3, the steel ball 4 and the cage together.

[0028] 2) Next, put the small end of the first inner ring 1 downward on the shaft at the upper end of the second inner ring 2, press the second inner ring 2 to fix it, and apply a downward force on the large end of the first inner ring 1. The pressure F1 is preloaded so that the small end surface of the first inner ring 1 and the shoulder of the second inner ring 2 maintain a distance a, and the value of a is 0.1-0.15mm.

[0029] 3) Sequentially apply forces at the upper and lower ends of the flange of the outer ring 3, so that the outer ring 3 can move up and down along the axial direction, and three displacement measuring instruments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com