Support device for rear axle assembly of automobile production line

A technology for automobile production lines and support devices, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor speed and balance of brakes and rear trailing arms, difficulty in meeting consistent production, and high labor intensity for operators. To achieve the effect of reducing the difficulty of assembly, wide range of use, and eliminating the dislocation of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

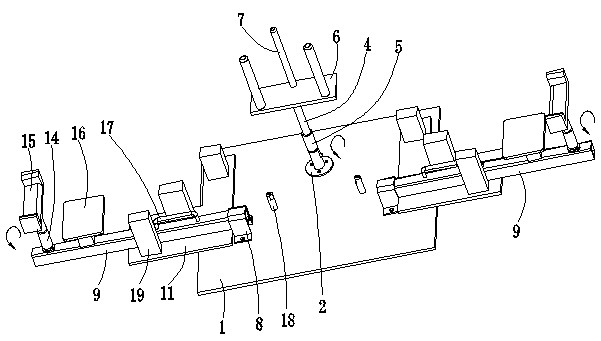

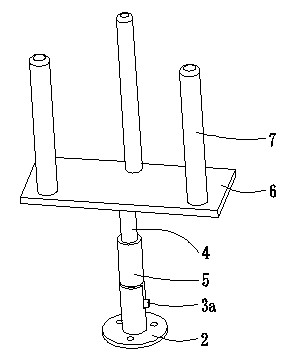

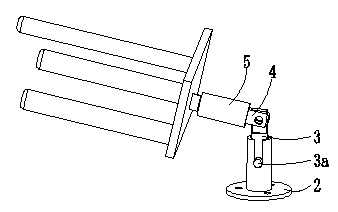

[0027] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0028] like figure 1 , figure 2 , image 3 As shown, the bottom plate 1 is a rectangular plate structure, and a base 2 is arranged in the center of the rear of the upper plate surface of the bottom plate 1. The base 2 is composed of a disc and a short tube. The disc is fixed to the bottom plate 1 by a plurality of bolts evenly distributed around the circumference Connection, a short tube perpendicular to it is fixed in the middle of the disc, and the short tube is sleeved with the lower end of the upright column 3 . The upper end of the short tube is provided with an opening from top to bottom, and the small post 3a in the middle of the upright post 3 is clamped into the opening to prevent the upright post 3 from rotating in the circumferential direction. The upper end of the upright column 3 is a flat cuboid, and the flat cuboid extends between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com