Triangular rear crawler belt assembly

An assembly and triangular technology, applied in the field of triangular rear track assembly, can solve problems such as difficulty in ensuring the position and dimensional accuracy of component parts, lack of free function of freewheel components, complex structure of load-bearing brackets, etc., to meet the requirements of consistent production and oil injection Convenience, speed and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

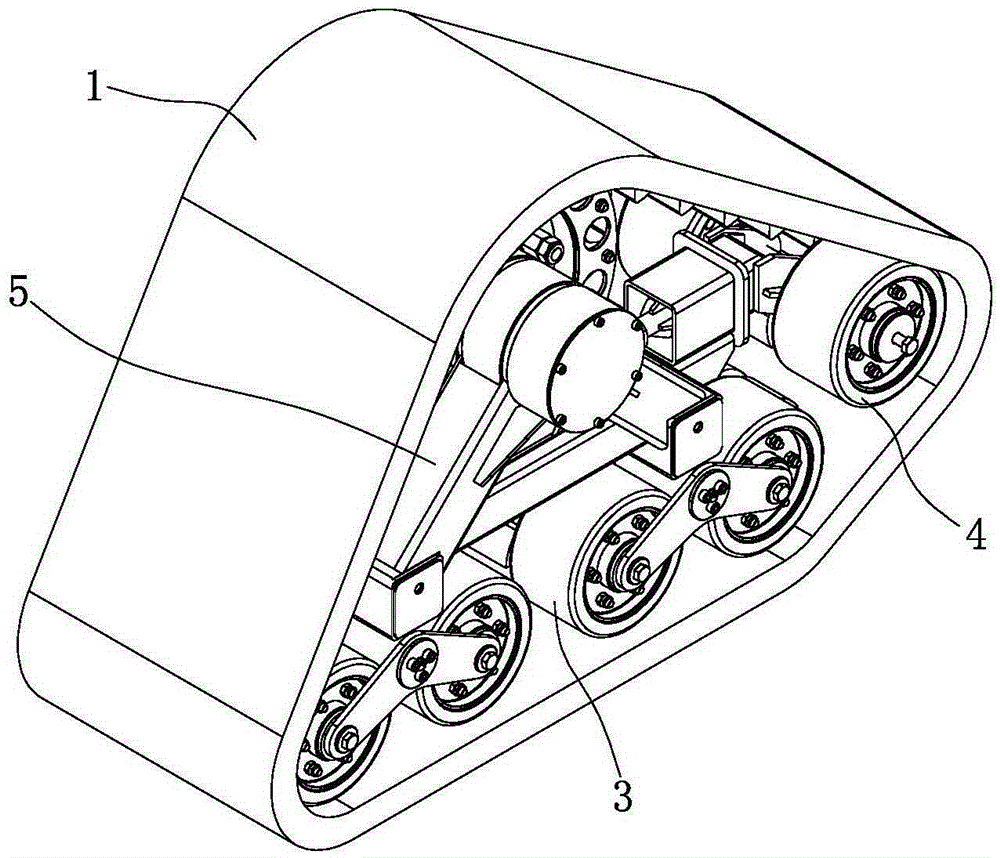

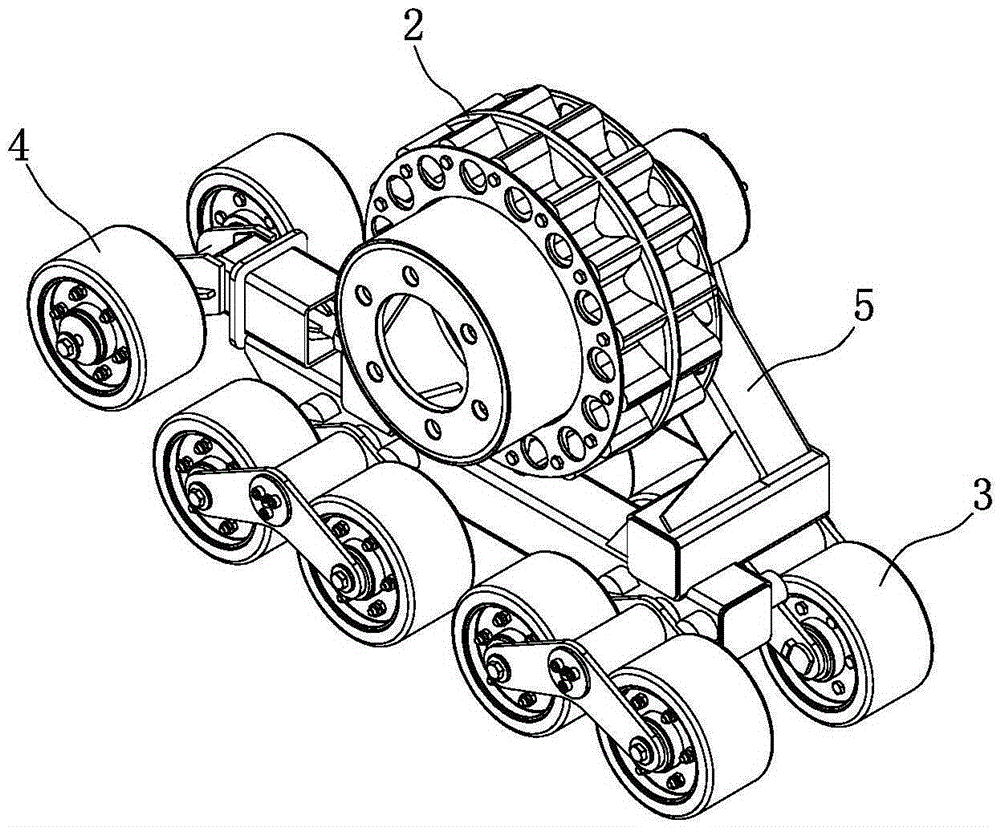

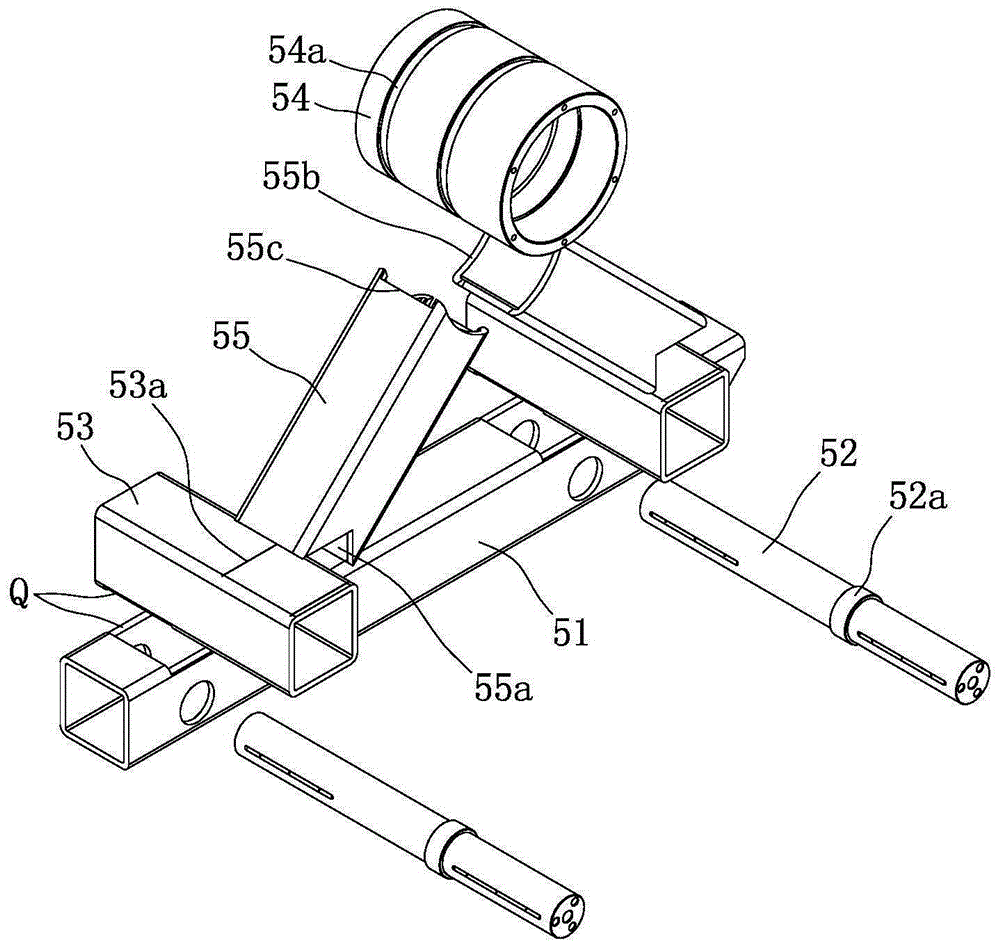

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the load-bearing bracket 5 is composed of a longitudinal beam 51, a swing main shaft 52, a beam 53, a bearing chamber 54, an oblique beam 55, a first sealing plate 56 and a second sealing plate 57, and the like. Wherein, the longitudinal beam 51 , the cross beam 53 and the inclined beam 55 are all square tubes, and the front and rear ends of the longitudinal beam 51 are provided with a swing main shaft 52 along the transverse direction, and the swing main shaft 52 is perpendicular to the longitudinal beam 1 . An annular boss 52a is integrally formed on the shaft body of the swing main shaft 52, and the annular boss 52a abuts against the side of the longitudinal beam 51. Beam 51 is welded and fixed.

[0040] Such as image 3 , Figure 4 , Figure 5 As shown, cross beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com