Clamping tool for motorcycle frame printing

A technology for clamping tooling and motorcycles, applied in printing devices, workpiece clamping devices, printing and other directions, which can solve the problems of easy shaking of the head tube of the frame, deviation of the marking position of the frame, and inconsistent production. , to achieve the effect of ingenious design, high clamping accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

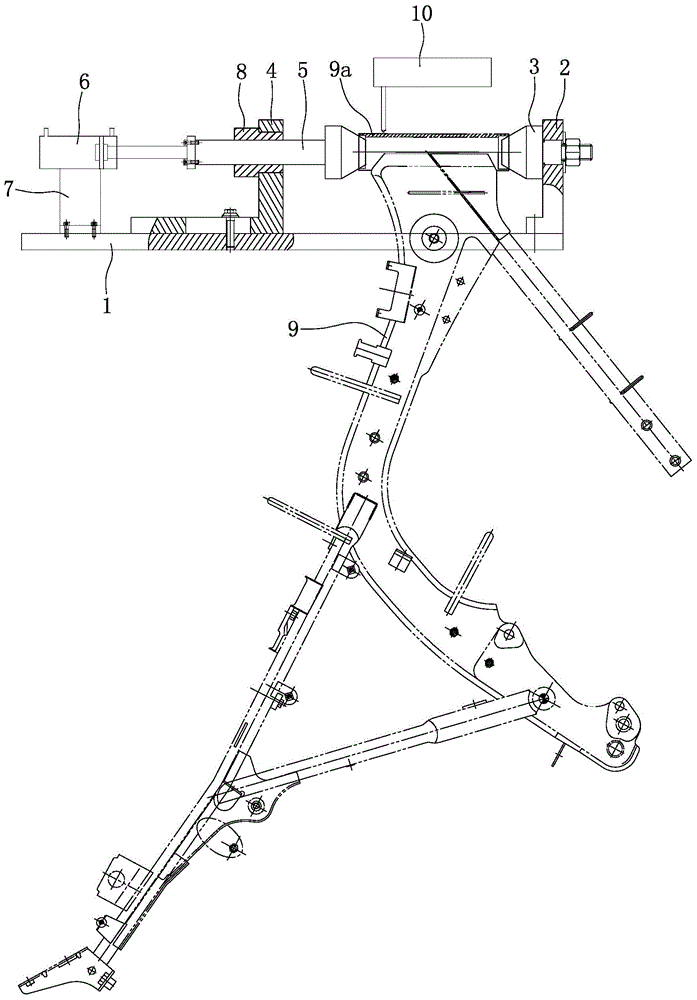

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

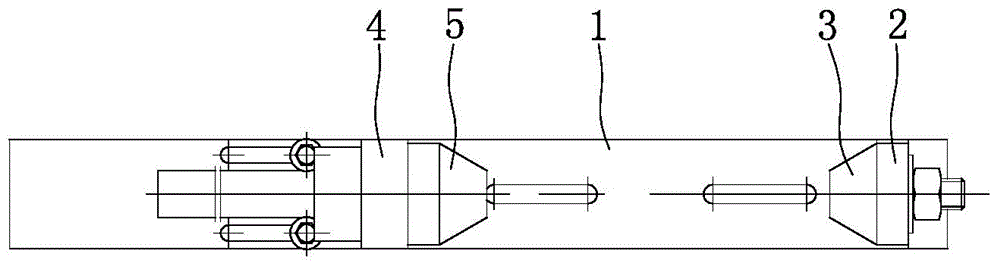

[0017] like figure 1 , figure 2 As shown, the base plate 1 is arranged on a workbench (not shown in the figure), and the base plate 1 is a rectangle whose length is obviously greater than the width. The front end of the base plate 1 is provided with a front positioning plate 2, the front positioning plate 2 is "L" shaped, the bottom end of the front positioning plate 2 fits with the front end of the base plate 1, and is fixed by the first bolt. The holes through which the first bolts pass are long strips extending forward and backward. The first positioning column 3 is arranged on the front positioning plate 2, and the first positioning column 3 is set on the upper part of the front positioning plate 2, and is locked by a nut. The rear end of the first positioning column 3 is a conical head with a large front and a small rear. .

[0018] like figure 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com