High-density packaged element positioning method based on speeded up robust features (SURFs)

A positioning method and component technology, applied in the direction of instruments, measuring devices, optical devices, etc., can solve problems such as large errors, failure to meet production requirements, and decreased positioning accuracy of key points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

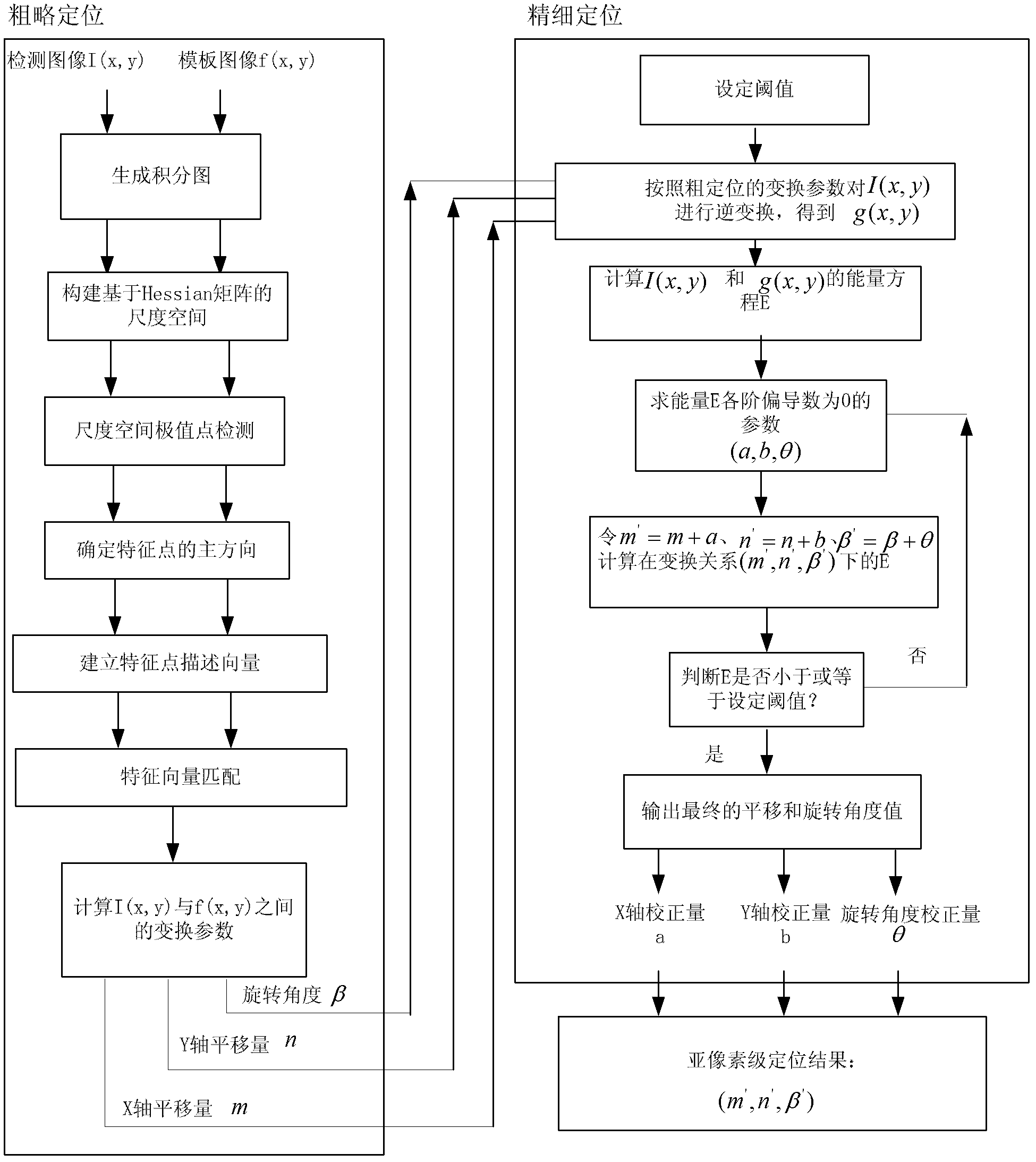

[0056] like figure 1 As shown, a SURF-based high-density packaging component positioning method of the present invention comprises the following steps:

[0057] S1 Rough positioning: Input the image to be registered I(x, y), use the SURF registration method to calculate the rough transformation relationship (m, n, β) between I(x, y) and the template image f(x, y), Among them, m and n are the translation parameters in the x and y directions respectively, and β is the rotation angle; specifically, the following steps are included:

[0058] S1.1 Generate integral images according to images I(x, y) and f(x, y):

[0059] For a given image, such as I(x, y), point (x, y) is a certain point in the integral image, then the integral image value I∑ of this point is the origin of I(x, y) and (x, y) The sum of the pixel values of all the pixel points in the rectangular area formed by the pixel points. Using the integral image, the calculation of the sum of all pixel values in any re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com