Liquid crystal module fixing mechanism for mobile terminal

A mobile terminal and liquid crystal module technology, applied in the direction of telephone structure, optics, instruments, etc., can solve the problems of poor width, poor experience, high production cost and inability to deliver in large quantities, so as to improve seismic protection and reduce production costs. , the effect of reducing thickness and width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. For ease of description, the "front" referred to in the following embodiments refers to the surface of the mobile terminal facing the user during use, and the "rear" referred to refers to the surface of the mobile terminal facing away from the user during use. Unless otherwise specified, the front and back of the mobile terminal is the thickness direction, and the left and right sides of the mobile terminal are the width direction.

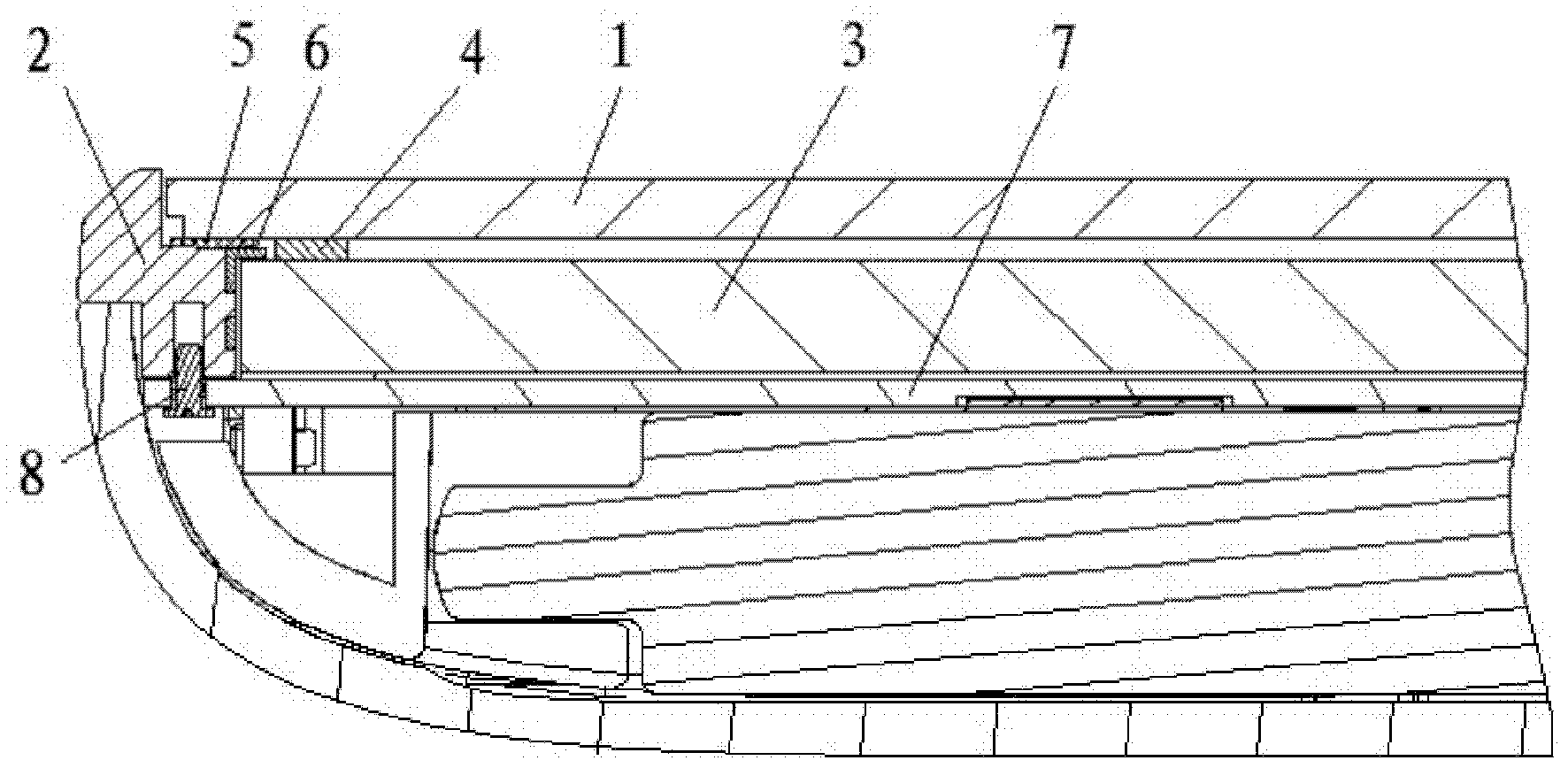

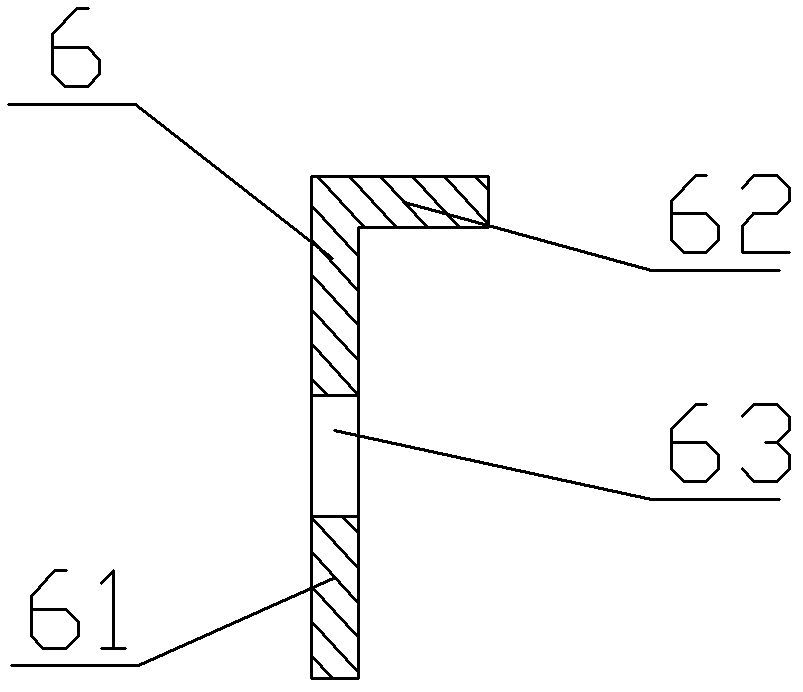

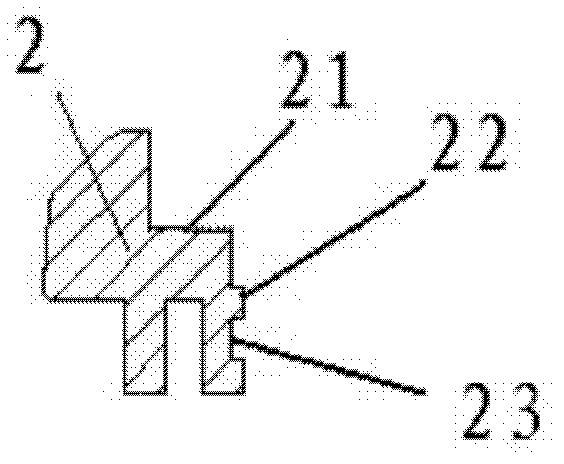

[0024] Such as figure 1 As shown, the liquid crystal module fixing mechanism of the mobile terminal in this embodiment includes a touch screen 1 and a front case 2 of the mobile terminal. A platform 21 for supporting the touch screen 1 is formed on the front surface of the mobile terminal front shell 2 (see image 3 ), and the flange used to protect the touc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com