Joining method, joining appliance and fastening element

A technology for fixing components and appliances, which is applied in the direction of connecting components, threaded fasteners, bonding methods of adhesive heating, etc., to achieve the effect of easy release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

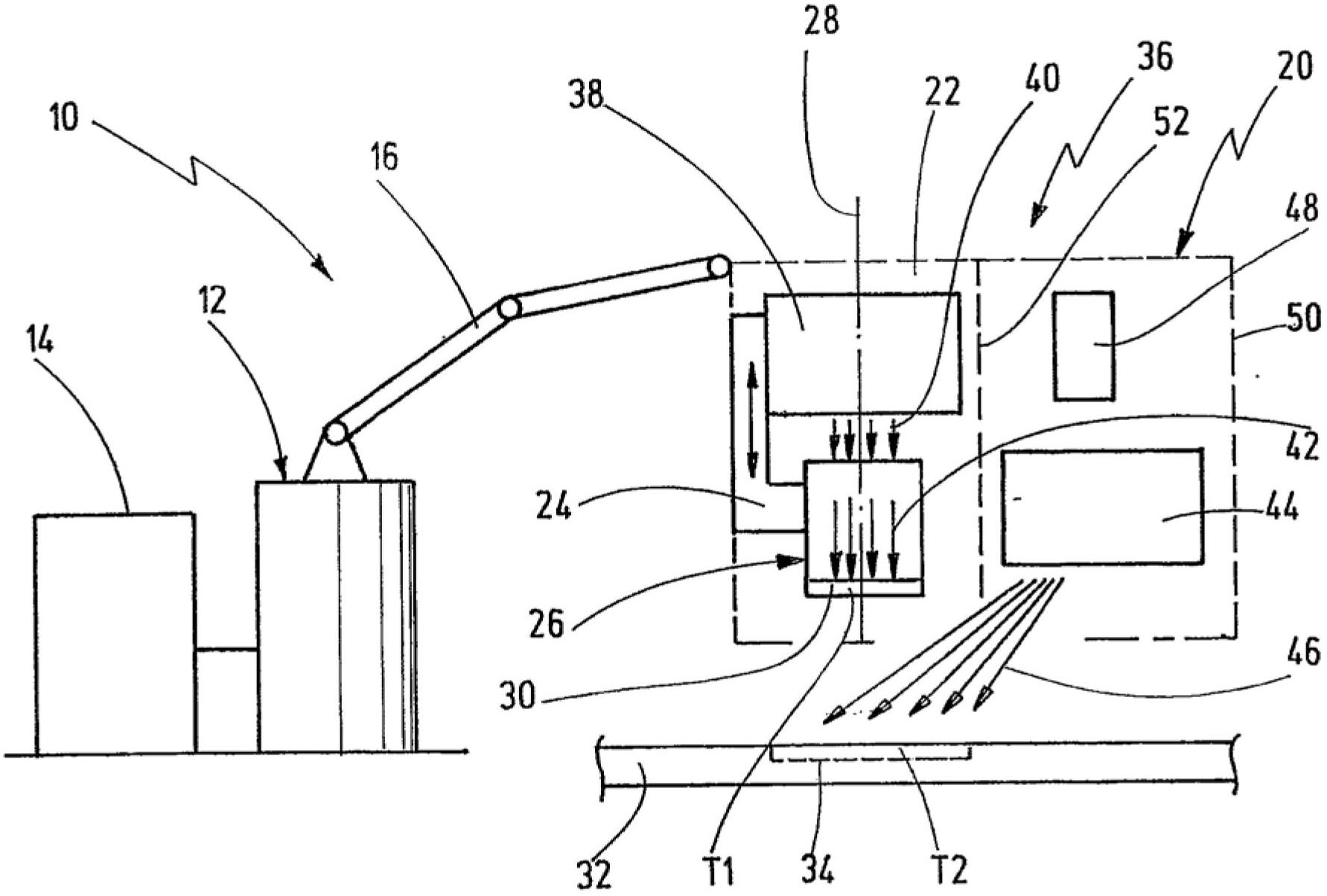

[0083] exist figure 1 In , a first embodiment of the connection device according to the invention is designated with the general reference numeral 10 . The connecting device 10 comprises a robot arm 12 which has at least one arm 16 in a known manner. Furthermore, the connecting device 10 has a control / energy supply unit 14 which is connected to the manipulator 12 .

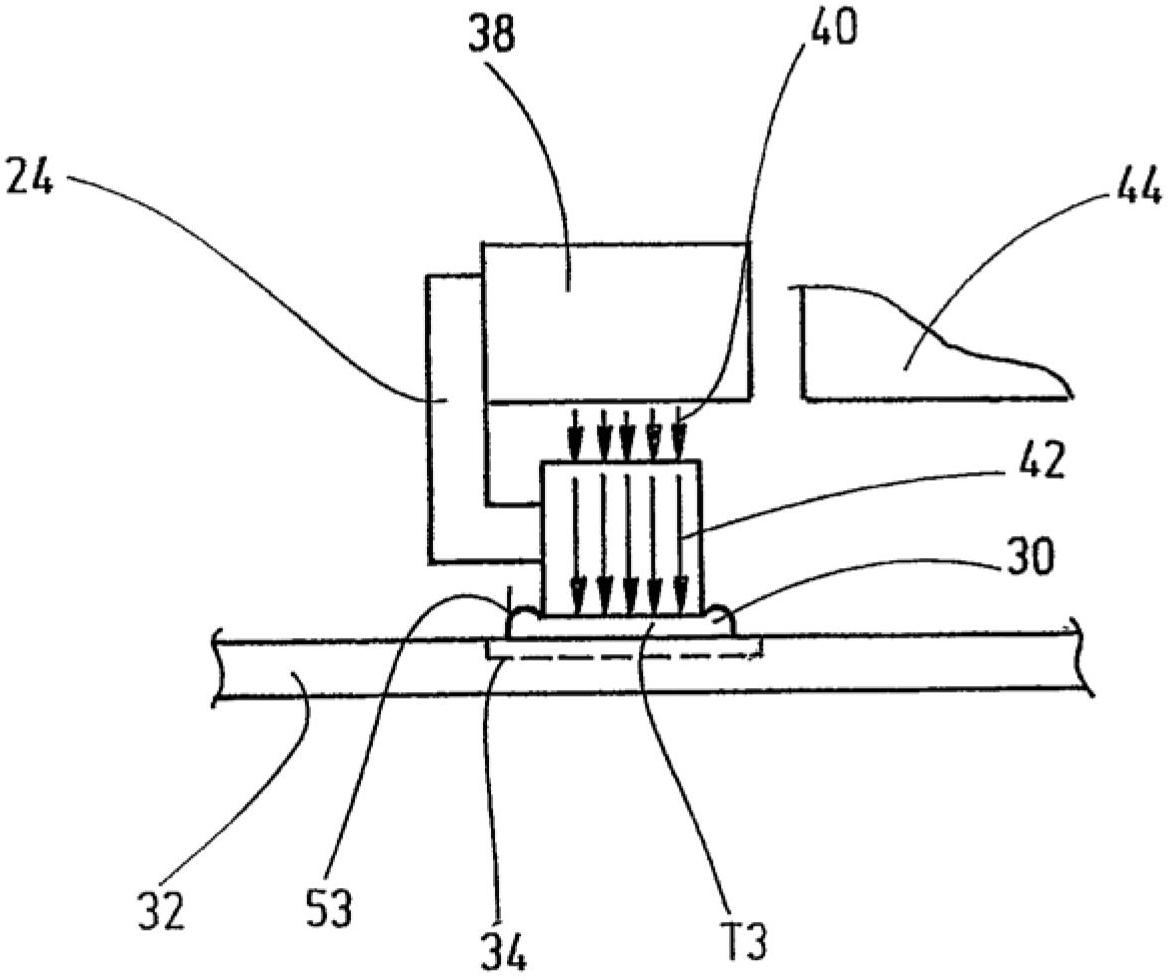

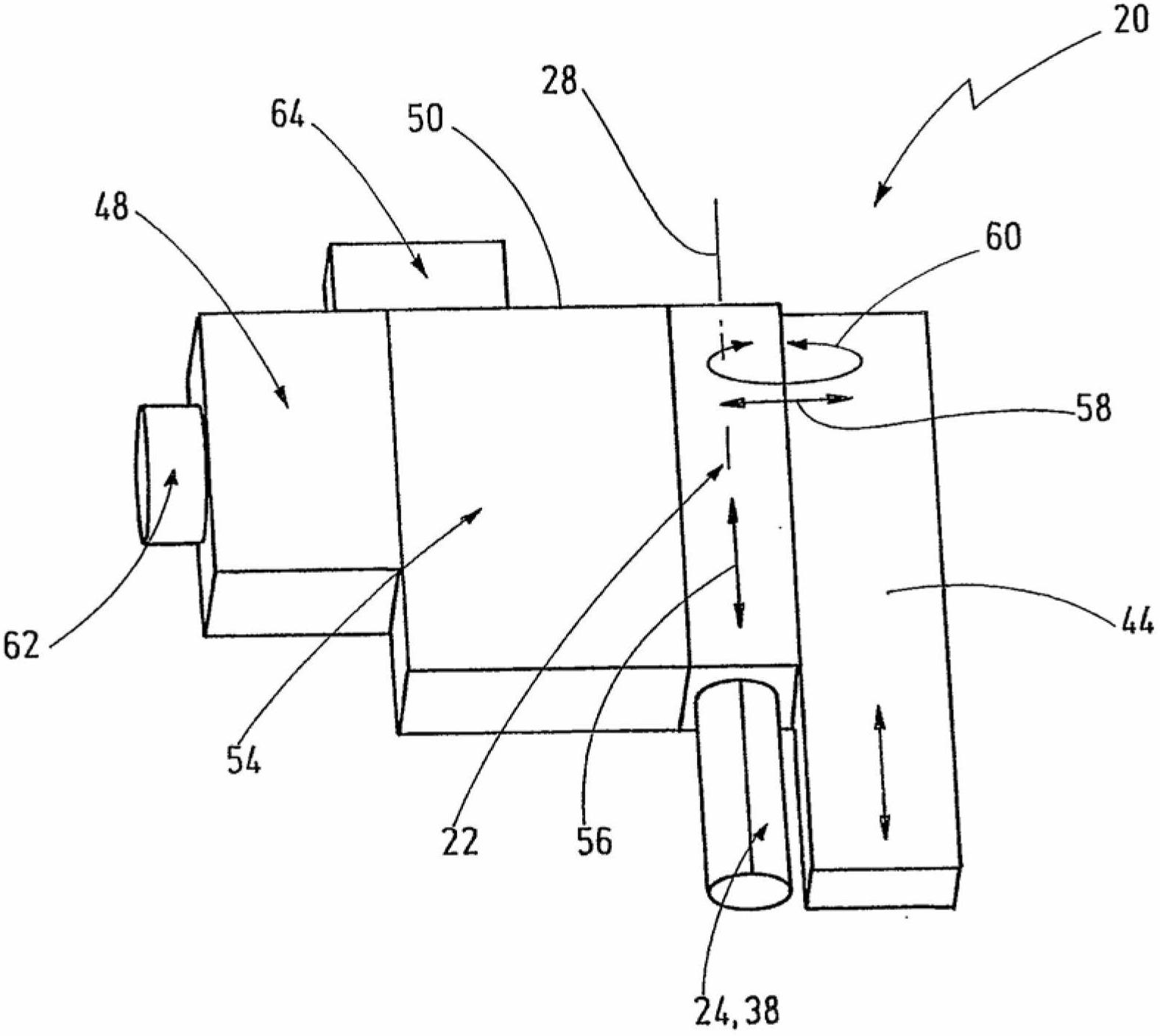

[0084] Provided on the arm 16 is a connection head 20 which is connected to the control / energy supply unit 14 via a flexible tubing combination (not shown). The connection head 20 includes a connection tool 22 . The connecting tool 22 has a holding device 24 for a fastening element 26 and is designed to move together with the fastening element 26 held thereon along a connection axis 28 , as indicated by the double arrow.

[0085] The fixing element 26 has an adhesive surface, not marked in more detail, to which an adhesive 30 is applied, which adhesive is initially heat-meltable and subsequently heat-curable. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com