Method for preparing 1-methylcyclopropene

A technology of methylcyclopropene and lithium methylcyclopropene, which is applied in the field of preparation of organic compounds, can solve the problems of no purification and washing, reduce process stability, increase process complexity, etc., avoid absorption-release steps, The effect of mild synthesis and storage conditions, and simple and easy-to-operate release methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

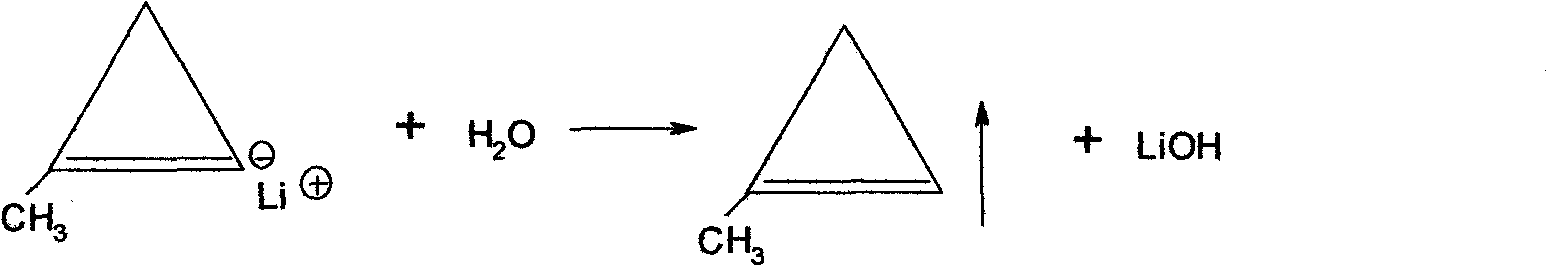

[0047] Synthesize 1-methylcyclopropene lithium with lithium diisopropylamide, add 130 grams (0.364mol) of 30% lithium diisopropylamide (suspended in liquid paraffin) and 0.4 grams of triethylamine in a 250 mL four-necked flask amine, stirred and heated to 40°C under the protection of nitrogen replacement.

[0048] In one hour, 13.4 g (0.147 mol) of 3-chloro-2-methylpropene was added dropwise into the four-neck flask using a constant pressure dropping funnel. After the dropwise addition, the reaction was continued for 30 minutes. The whole process is always under nitrogen protection. After the reaction, the system was cooled to room temperature, and 0.67 g of 3-chloro-2-methylpropene remained in the detected system, which represented a conversion rate of 3-chloro-2-methylpropene of 95%.

[0049] Then vacuumize under stirring to remove unreacted 3-chloro-2-methylpropene, and the absolute pressure of the system is about 0.1Kpa.

[0050] Take the above-mentioned 1-methylcyclopr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com