Lens array and optical module provided therewith

一种透镜阵列、透镜面的技术,应用在光学、光学元件、光导等方向,能够解决制造困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

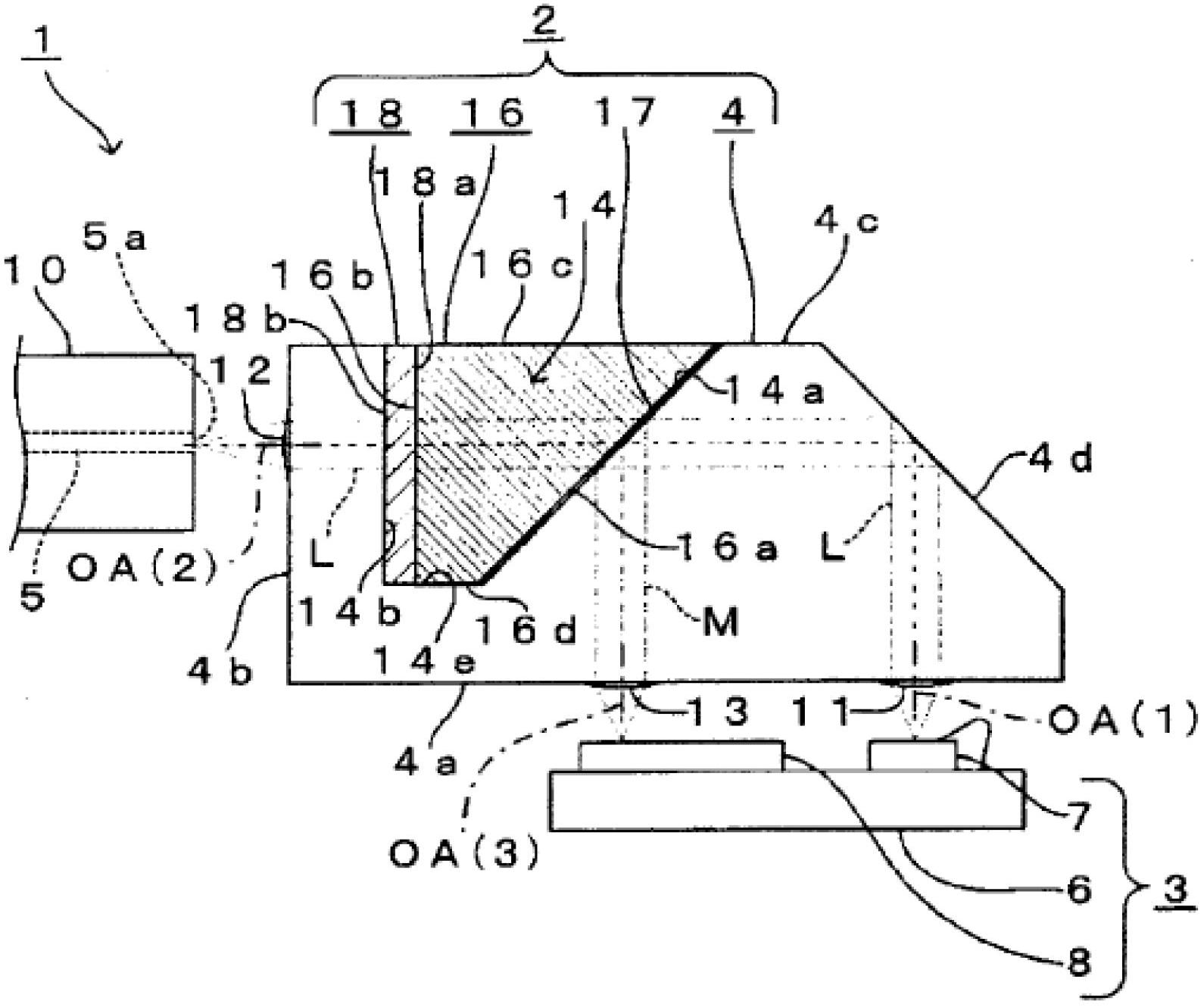

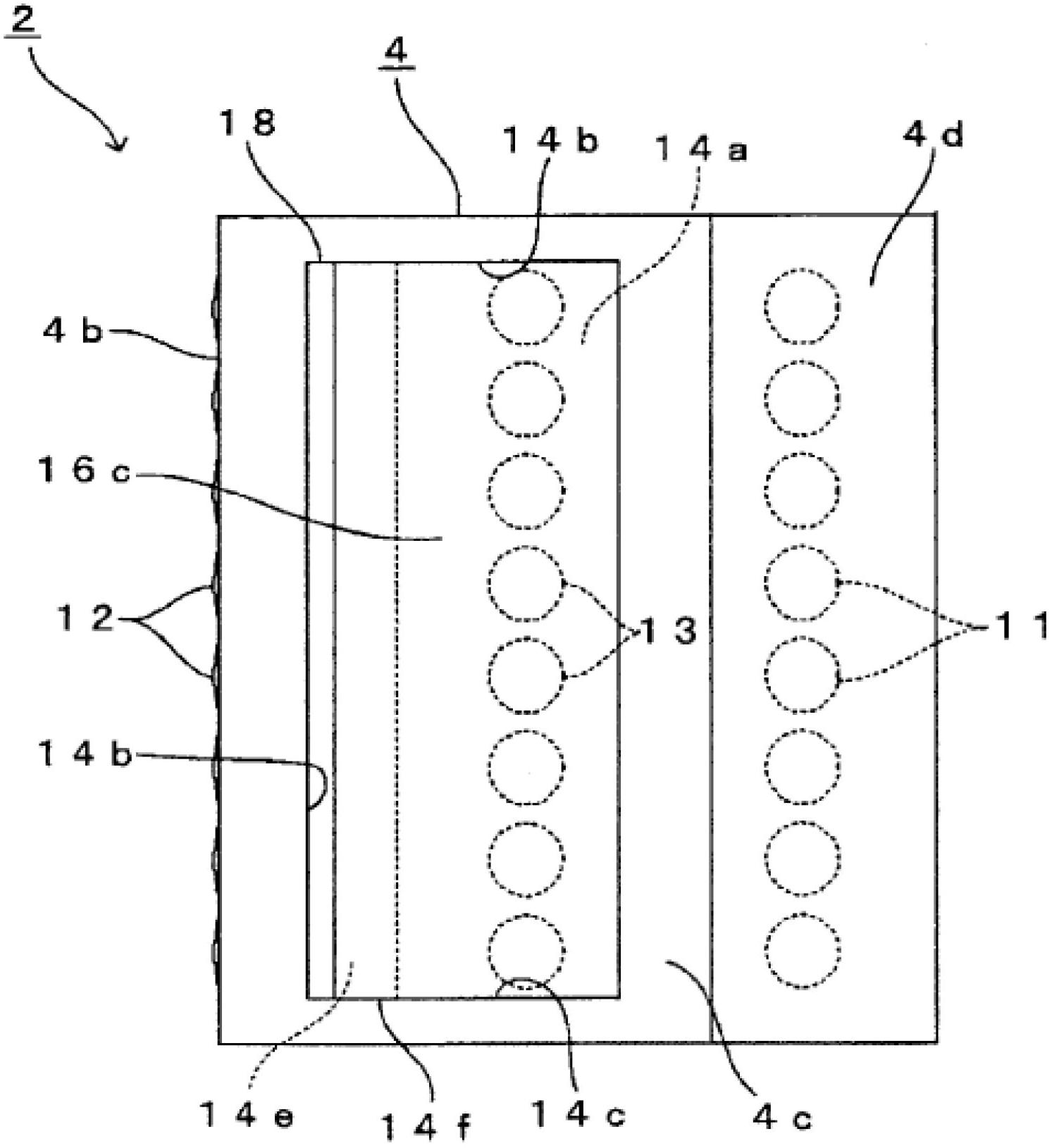

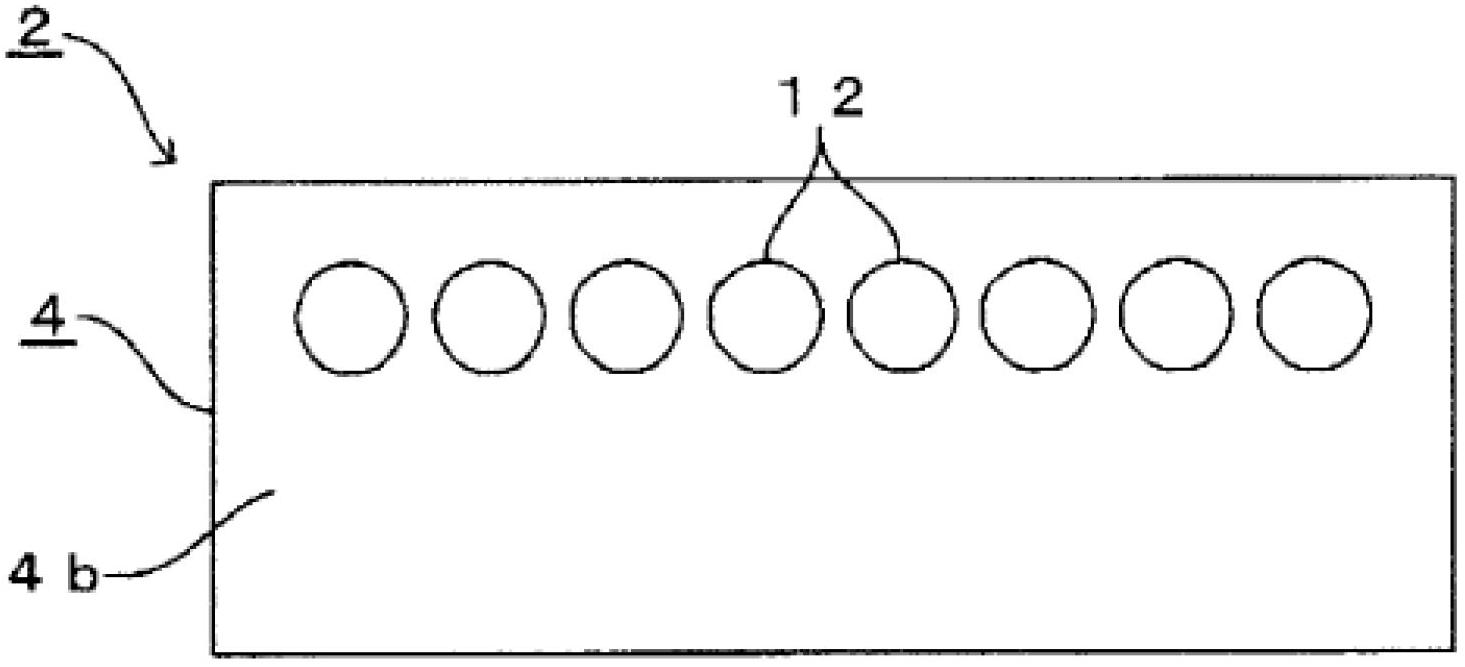

[0089] Below, refer to Figure 1 to Figure 6 Embodiment 1 of the lens array of the present invention and an optical module including the lens array will be described.

[0090] figure 1 It is the outline of the optical module 1 in this embodiment and the longitudinal cross-section of the lens array 2 in this embodiment. Figure 1 The schematic structure diagram shown. figure 2 yes figure 1 A top view of the lens array 2 shown. image 3 yes figure 1 Left side view of lens array 2 is shown. Figure 4 yes figure 1 Right side view of lens array 2 shown. Figure 5 yes figure 1 Bottom view of lens array 2 shown.

[0091] Such as figure 1 As shown, the lens array 2 in this embodiment is arranged between the photoelectric conversion device 3 and the optical fiber 5 .

[0092] Here, the photoelectric conversion device 3 has a plurality of light emitting elements 7 on the surface of the semiconductor substrate 6 facing the lens array 2, and the plurality of light emitti...

Embodiment approach 2

[0139] Next, regarding Embodiment 2 of the lens array of the present invention and an optical module including the same, focusing on the differences from Embodiment 1, refer to Figure 7 ~ Figure 12 Be explained.

[0140] In addition, in this embodiment, for the Figure 1 to Figure 6 For parts with the same or similar structure, use the same Figure 1 to Figure 6 The same reference numerals are used for description.

[0141] Figure 7 It is the outline of the optical module 21 in this embodiment and the longitudinal cross-section of the lens array 22 in this embodiment. Figure 1 The schematic structure diagram shown. Figure 8 yes Figure 7 A top view of lens array 22 is shown. Figure 9 yes Figure 8 Left side view of the lens array shown. Figure 10 yes Figure 8 Right side view of the lens array shown. Figure 11 yes Figure 8 Bottom view of the lens array shown.

[0142] In this embodiment, as one of the differences from Embodiment 1, when fixing the photoelec...

Embodiment approach 3

[0153] Hereinafter, regarding Embodiment 3 of the lens array of the present invention and an optical module including the same, focusing on differences from Embodiments 1 and 2, refer to Figure 13 to Figure 16 Be explained.

[0154] In addition, in this embodiment, for the Figure 1 to Figure 12 For parts with the same or similar structure, use the same Figure 1 to Figure 12 The same reference numerals are used for description.

[0155] Figure 13 It is the outline of the optical module 30 in this embodiment and the longitudinal section of the lens array 31 in this embodiment. Figure 1 The schematic structure diagram shown. Figure 14 yes Figure 13 A top view of lens array 31 is shown. Figure 15 yes Figure 14 Right side view of lens array 31 is shown.

[0156] Such as Figure 13 As shown, in this embodiment, the structure is similar to that of Embodiment 2 in that the side surface of the concave portion 14 extends upward from the first optical surface 14a and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com