Automatic stacking device of rice seedling raising and sowing plates

A technology for raising rice seedlings and sowing seedlings, which is applied in application, cultivation, agriculture, etc., can solve the problems of time-consuming and laborious stacking, inaccuracy, and uncoordinated manual stacking, achieve timely closing, avoid blockage of seedling trays, and improve sowing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

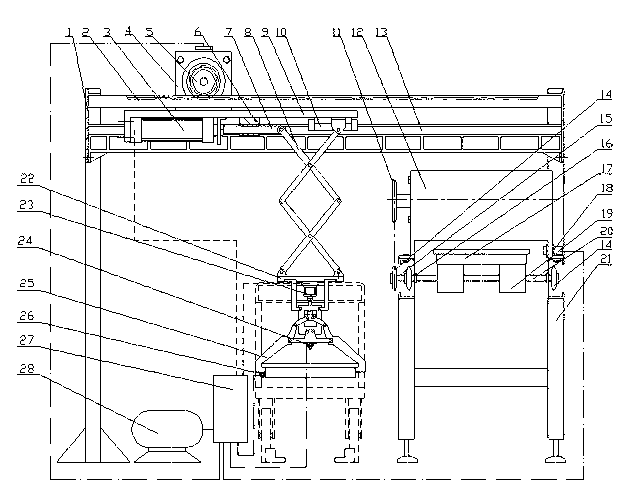

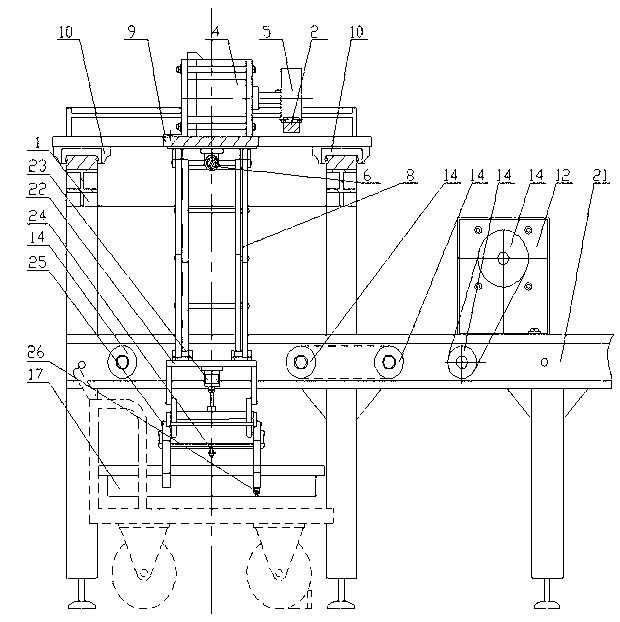

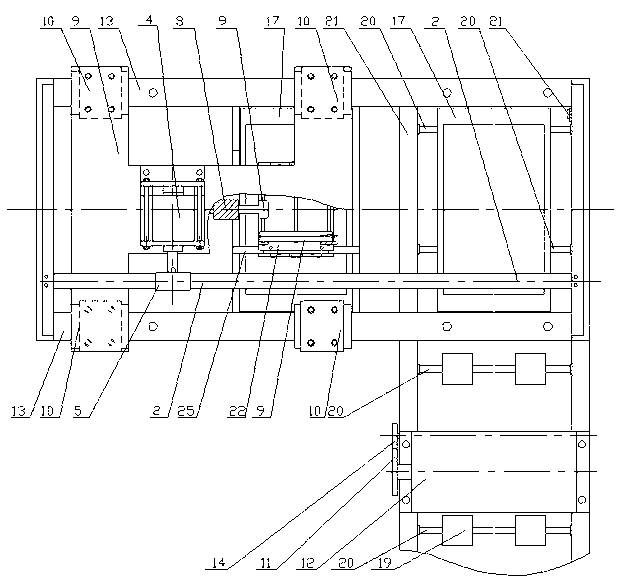

[0020] The present invention will be further described below in conjunction with accompanying drawing and example.

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the rice seedling raising and sowing seedling tray automatic stacking device includes a seedling tray conveying assembly, a seedling tray stacking assembly, a pneumatic assembly and a controller 27:

[0022] Seedling tray conveying assembly includes driving sprocket 11, reduction motor 12, driven sprocket 14, driving shaft 15, nylon bearing 16, seedling tray 17, photoelectric sensor 18, roller 19, driven shaft 20, conveying frame 21; 19 is installed on the driven shaft 20, a plurality of driven sprockets 14 are respectively fixed at both ends of the driven shaft 20, chain transmission is adopted between the multiple driven sprockets 14, and a plurality of driven shafts 20 are installed on the On the conveyor frame 21; the deceleration motor 12 is fixed on the conveyor frame 21, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com