Ultrasonic machining device and machining method for diamond microporous wire-drawing die

An ultrasonic processing and diamond technology, applied in the field of ultrasonic processing devices, can solve the problems of easy folding needles, folding needles, high difficulty and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to effectively solve the problem of frequent needle folding in the prior art when processing diamond micro-hole wire drawing dies, especially when processing diamond micro-hole wire drawing dies with an aperture ≤ 0.03 mm. The invention provides an ultrasonic machining device for aligning the machining center of the machining area by means of an observation / detection / correction system when grinding and polishing the diamond microhole wire drawing die.

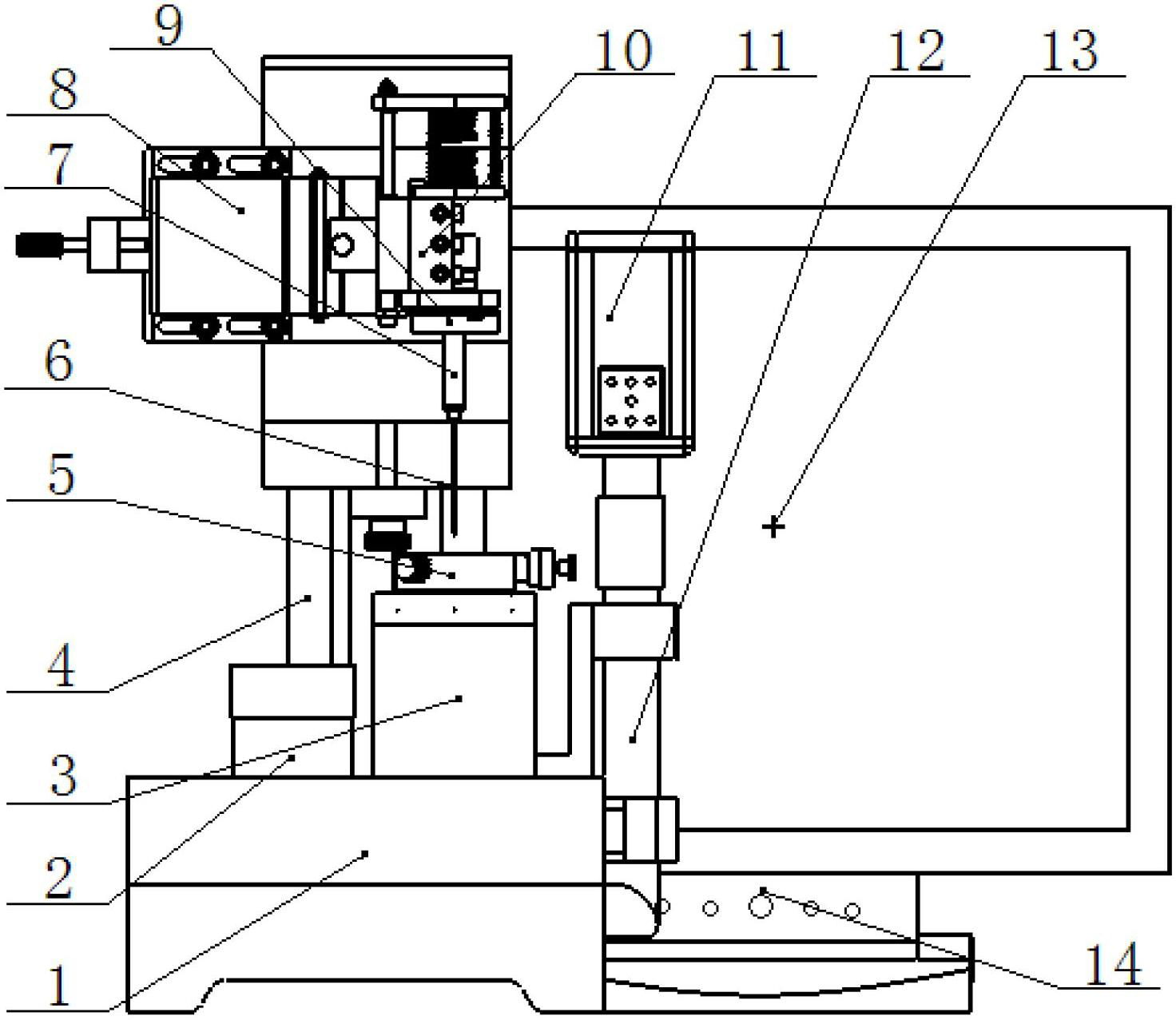

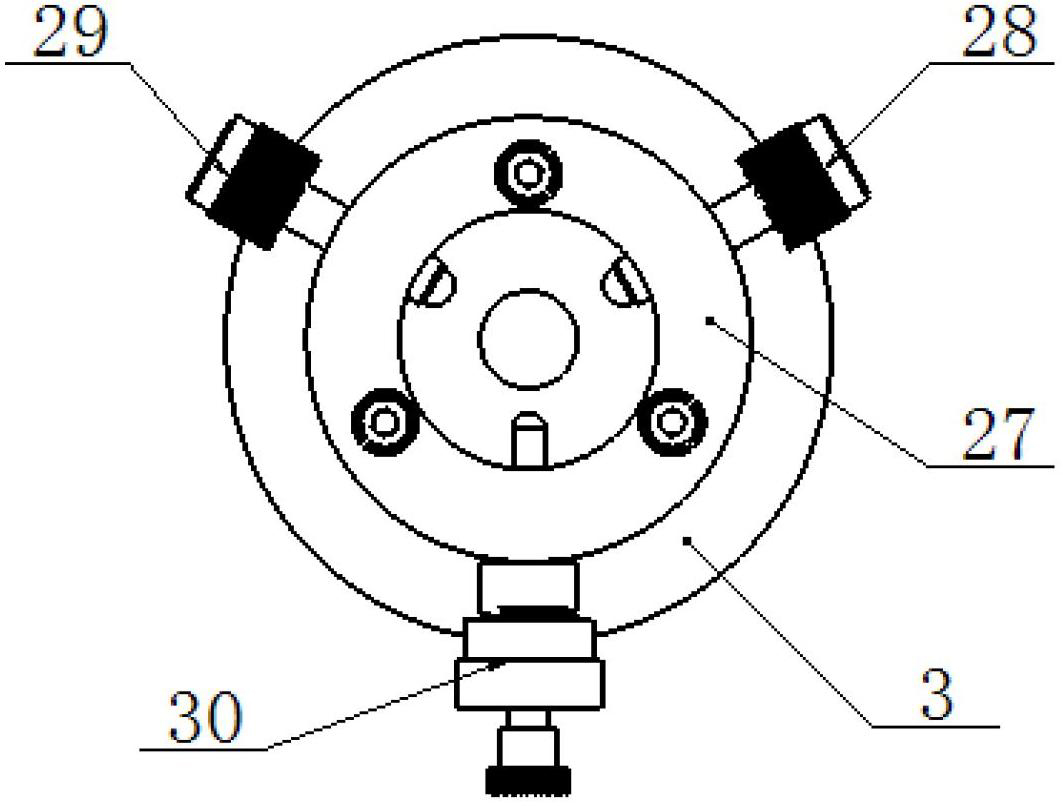

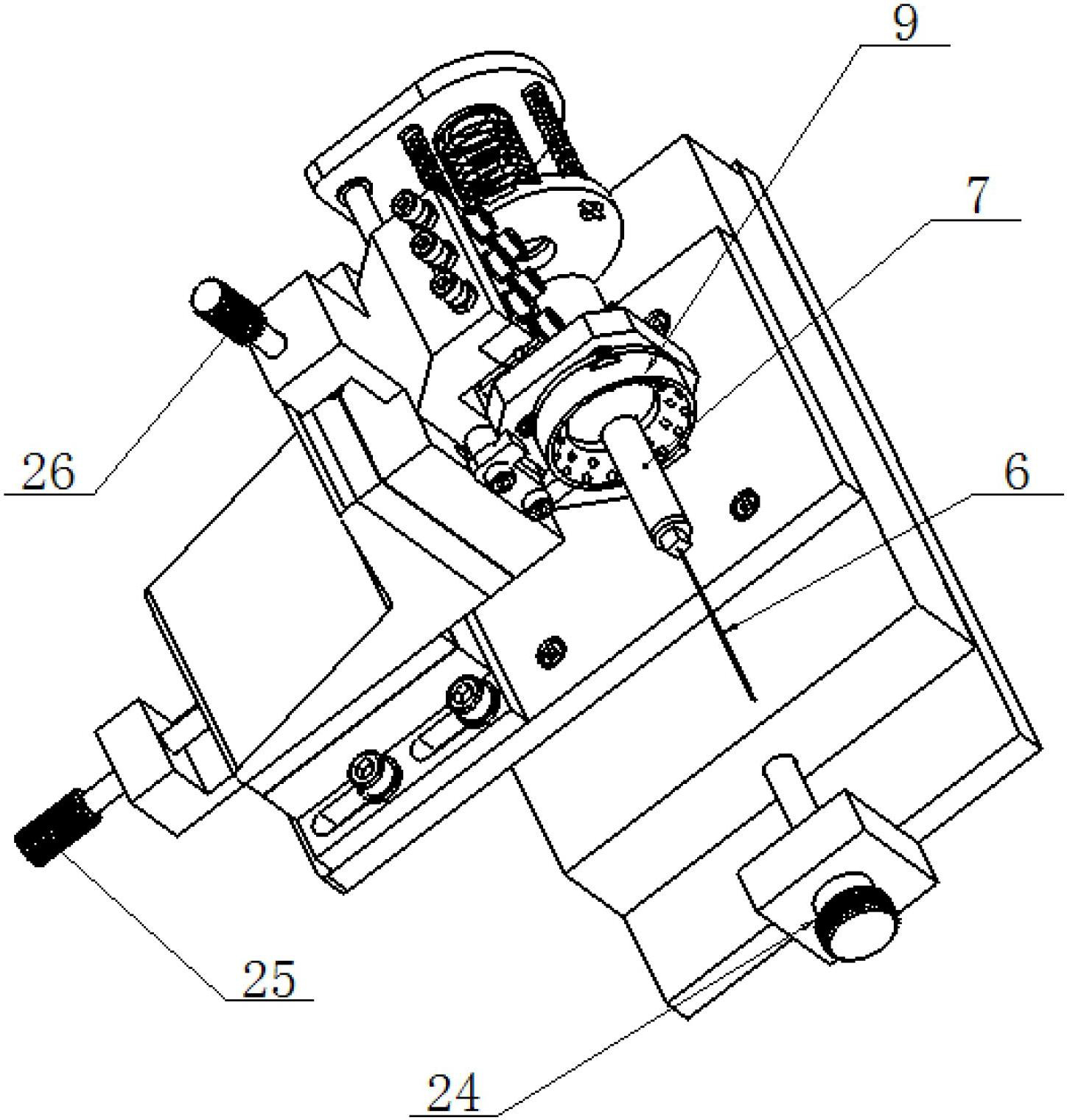

[0043] Such as figure 1 The ultrasonic processing device shown includes a device base 1 , a rotating motor 2 fixedly installed above the device base 1 , a rotary table 3 and a device column 4 . The rotary motor 2 is connected to the rotary table 3 by belts or chains, and the rotary motor 2 is used to drive the rotary table 3 to rotate. The rotary table 3 is used to fix the diamond microhole wire drawing die (hereinafter referred to as the die) to be processed, and drive the die to rotate. A mold centering mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com