Three-rod double-slide large-angle inclined jacking core-pulling ejector pin device

The technology of rod device and inclined ejector rod is applied in the field of three-bar double-slide large-angle inclined top core-pulling ejector rod device. , Easy to reset, prolong life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

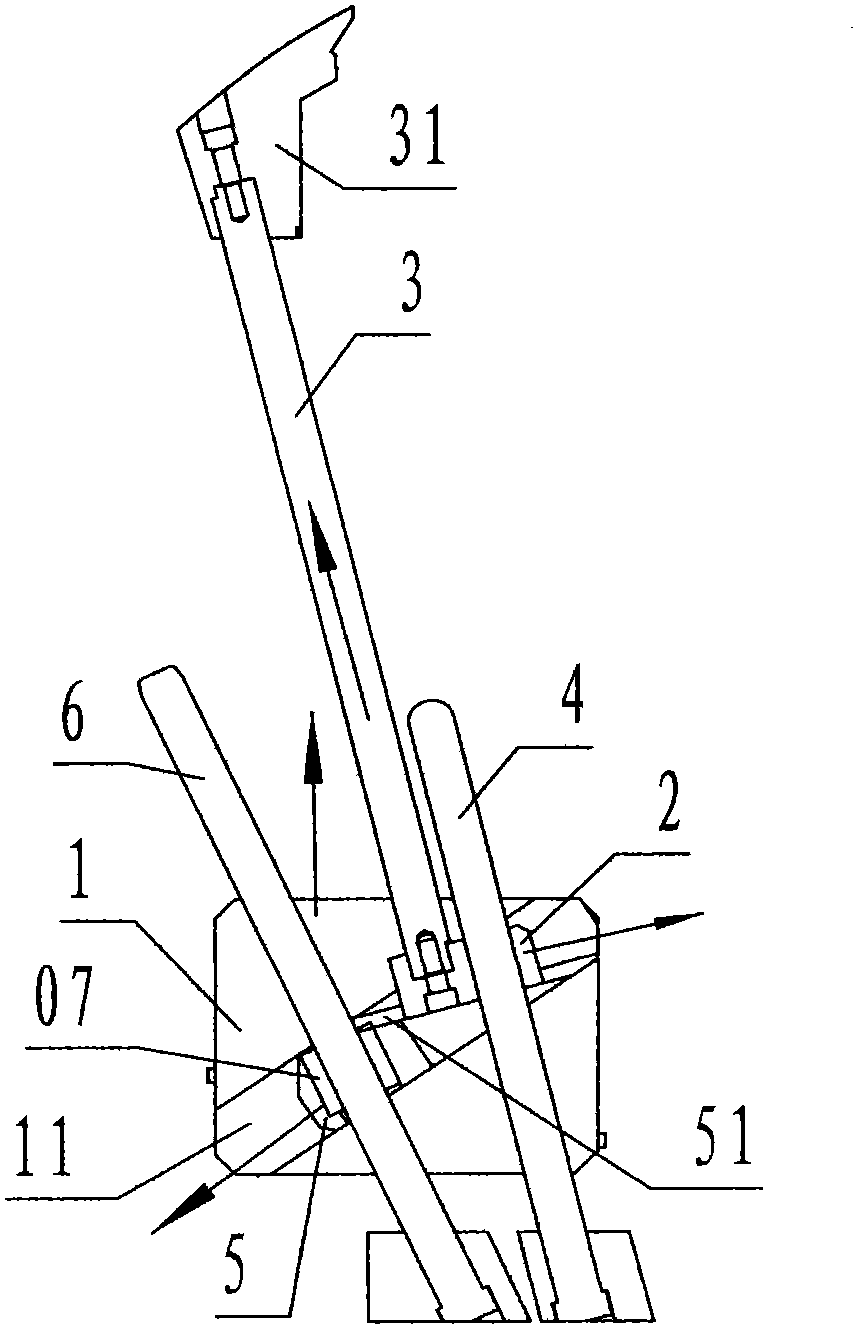

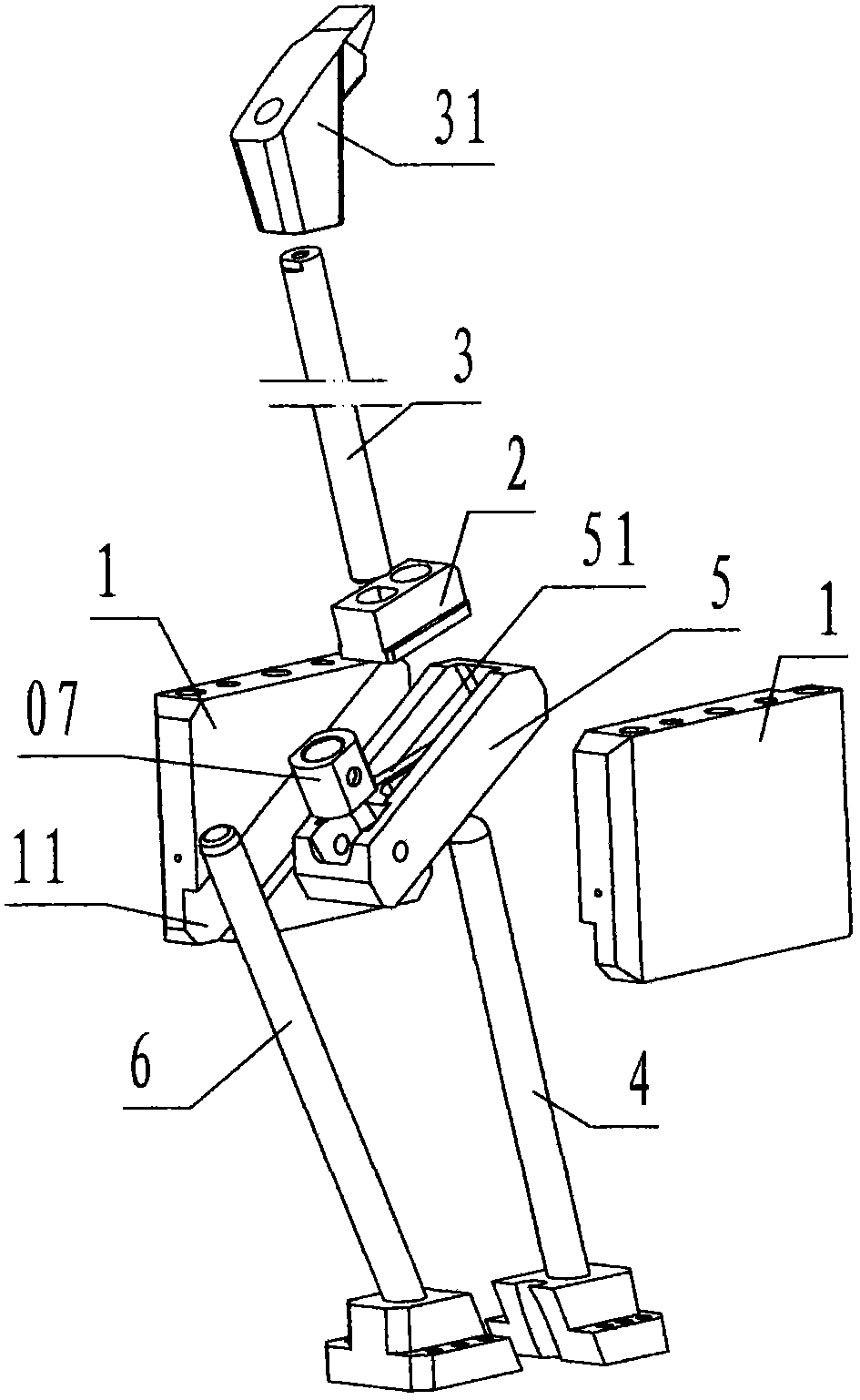

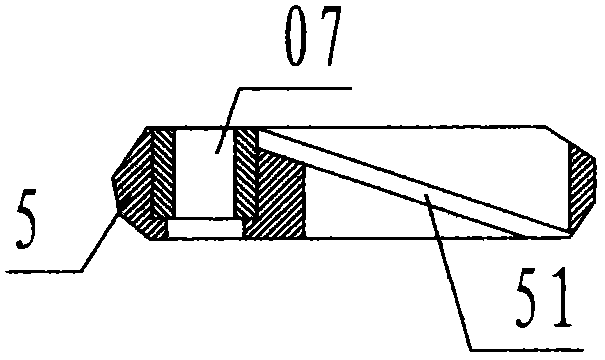

[0029] refer to Figure 1 to Figure 5 , a three-rod double-sliding large-angle inclined top core-pulling ejector device of the present invention includes an inclined sliding seat 1, an inclined sliding foot 2, an inclined ejector rod 3, a parallel guide rod 4, an auxiliary slider 5, and a guiding rod 6, Wherein: the inclined sliding seat 1 is a component composed of two confronting rectangular steel plates, and the opposite surface of the two steel plates of the inclined sliding seat 1 is provided with a groove from the upper right corner to the lower left corner, and the oblique section is rectangular. The formed A chute 11;

[0030] The inclined sliding foot 2 is a rectangular block-shaped steel component, and the left part above the inclined sliding foot 2 is provided with a step through hole with a positioning gap for orthogonally connecting the inclined ejector rod 3; the right side of the inclined sliding foot 2 The upper part is provided with a circular sliding hole th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com