Embossing machine

A printing machine and machine technology, which is applied in the field of automatic and high-efficiency printing machines, can solve the problems of color difference and unstable cloth quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

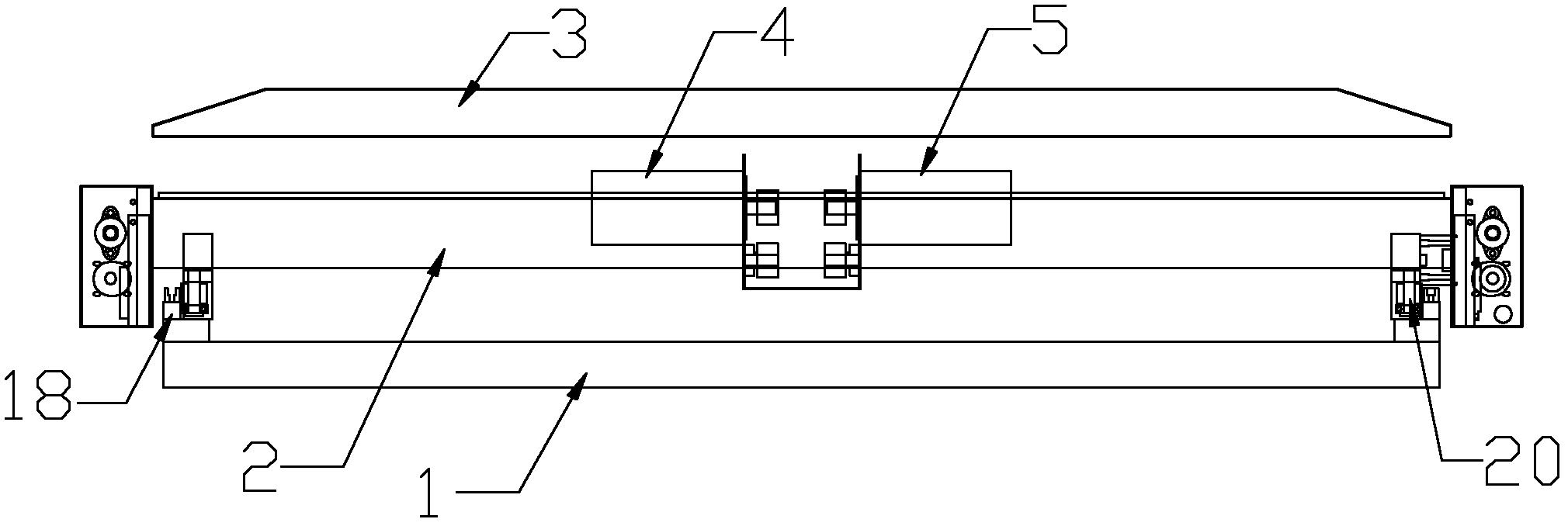

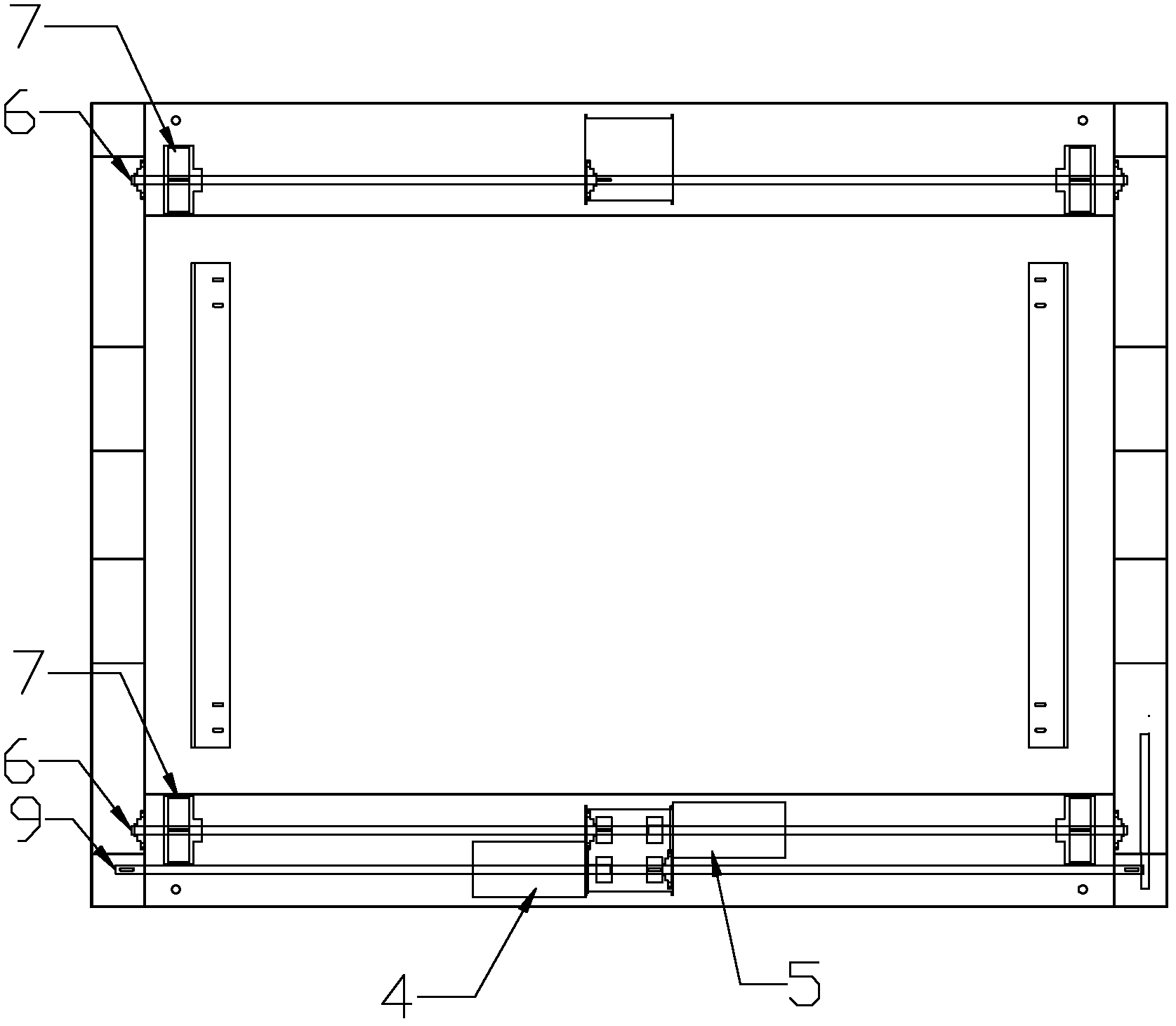

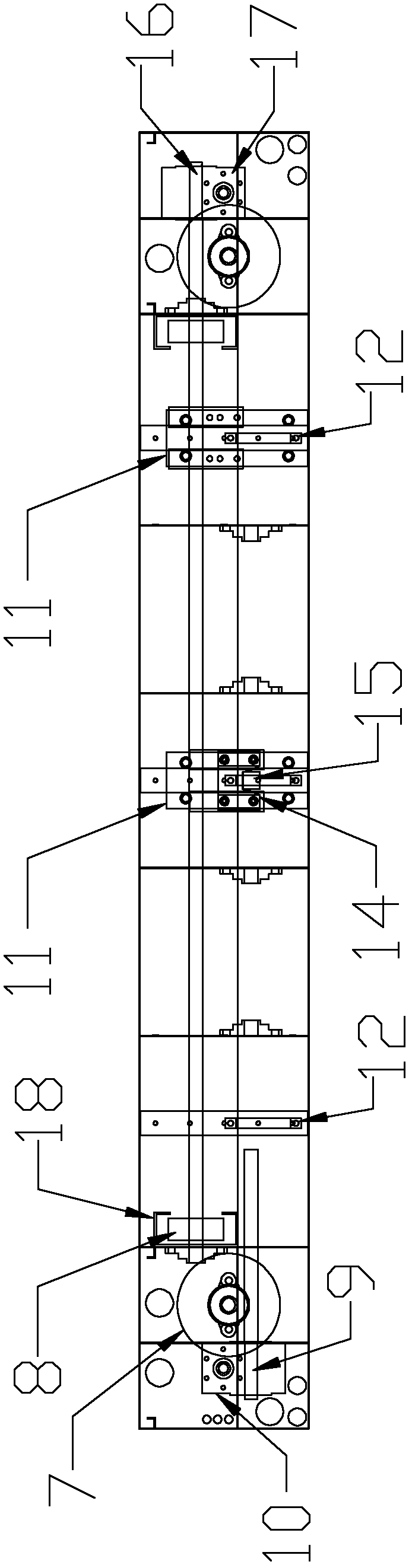

[0016] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the printing machine of the present invention includes a machine platform 1, a running platform 2, a machine cover 3 and a control module (not shown in the figure), and the running platform 2 is located between the machine platform 1 and the machine cover 3, the control module is located inside the machine 1. The control module is the control center of the printing machine, which issues various commands and responds accordingly through the received information. The treadmill 2 is provided with a walking device, a lifting device, a scraper device, a first servo motor 4 and a second servo motor 5 . The traveling device includes a traveling shaft 6, a traveling wheel 7 and a synchronous pulley 8. The first servo motor 4 provides power for the traveling shaft 6 to make it rotate together, and then drives the walking shaft 8 through the synchronous pulley 8. Wheel 7 also begins to rotate. Described elevating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com