Clip-type pig hair double-edged scraper

A clip-type, pig hair technology, applied in metal processing, etc., can solve the problems that affect the operation efficiency and difficult to remove the pig hair, and achieve the effect of easy removal and easy scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

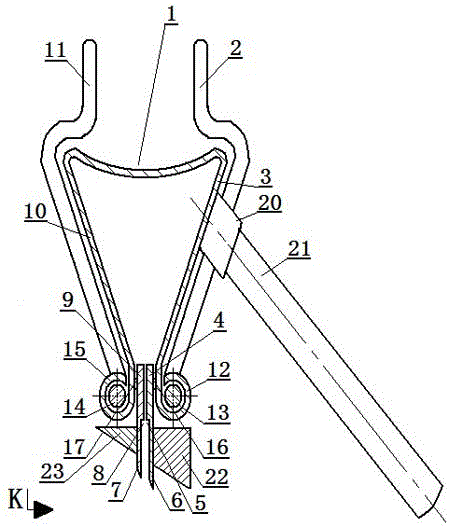

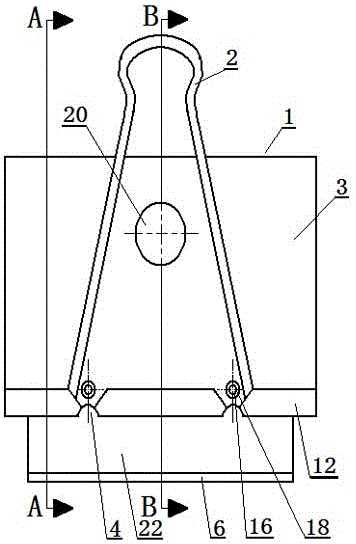

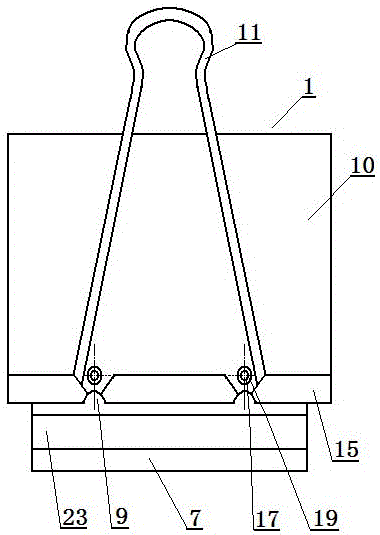

[0024] Embodiment: As shown in the accompanying drawings, a clip-type pig hair double-edged scraper is designed and manufactured, including a handle 21 and a clip body 1 processed from a single piece of elastic steel sheet, the left clip part 10 of the clip body 1 and The right grip part 3 is respectively provided with a left handle 11 and a right handle 2 which are processed by elastic steel wires. The front and rear two ends of the lower end of the part 3 are respectively rolled up to the right to form two right drums 12, and the front and rear ends of the lower end of the left handle 11 are respectively bent forward and backward to form two left extension shafts. 14. The front and rear ends of the lower end of the right handle 2 are respectively bent forward and backward to form two right extension shafts 13, and two left drums 15 and two right drums 12 are sleeved on two shafts respectively. On the outer diameter ends of the left extension shaft 14 and the two right extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com