Dust removal device special for resistive load box

A technology of resistive load and ash cleaning device, which is applied in the cleaning method using gas flow, removal of smoke and dust, transportation and packaging, etc., can solve the problems of poor cleaning effect and dust scattering, and achieve the effect of preventing dust scattering and quick cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

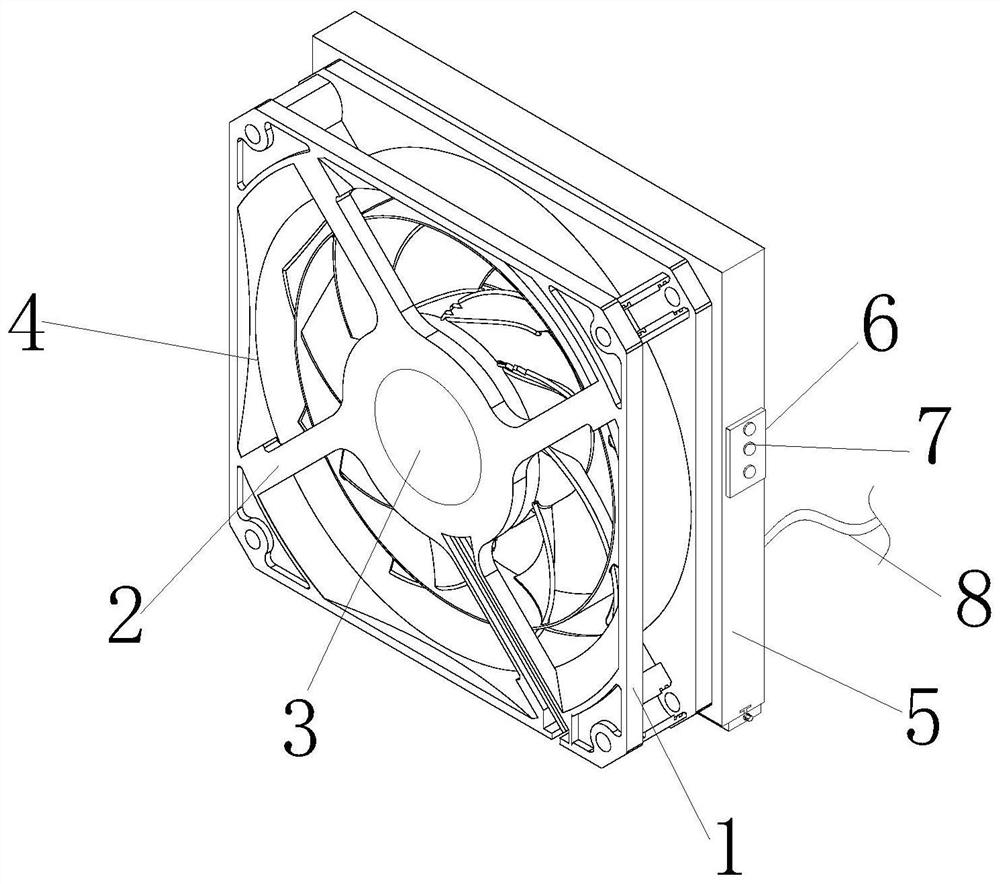

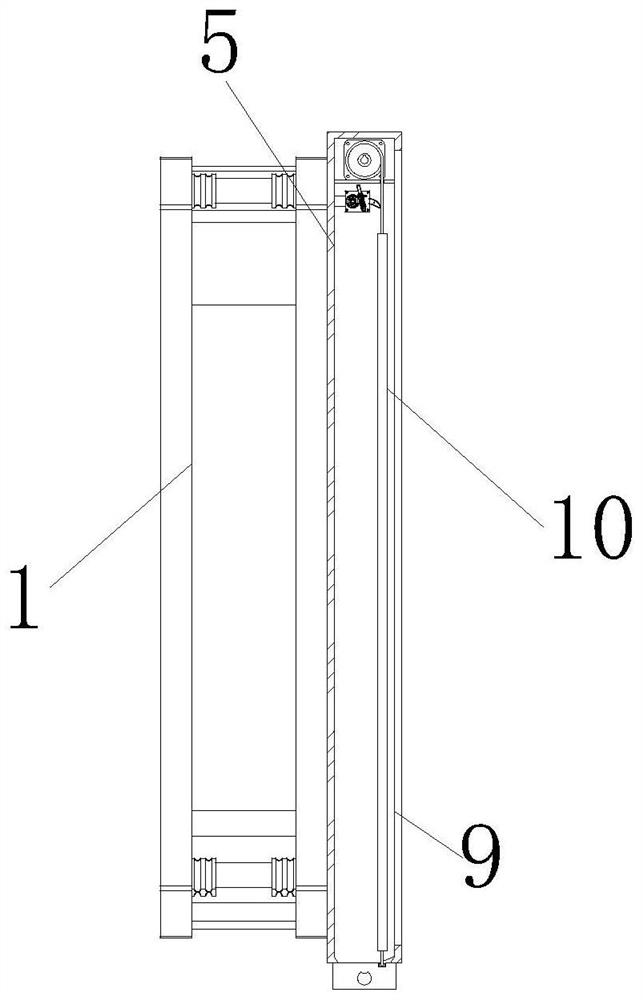

[0029] see figure 1 and figure 2 , the present invention provides a special cleaning device for a resistance load box through improvement, including a fixed frame 1, a rotating groove 4, a fixed frame 5, a discharge groove 9 and a blocking collection mechanism 10, the fixed frame 1 and the connecting frame 2 rear ends Bolt connection, the connecting frame 2 is locked and fixed with the front end of the fan 3 by screws, the middle part of the fixed frame 1 is provided with a rotation groove 4, the blocking collection mechanism 10 is installed and fixed inside the fixed frame 5, the fixed frame 1 is connected with the front end of the fixed frame 5 by bolts, and fixed The right end of the frame 5 is provided with a control panel 6, the front end of the control panel 6 is provided with a button 7, the rear end of the fixed frame 5 is fixed with a power lead 8, and the right end of the fixed frame 5 is provided with a discharge groove 9.

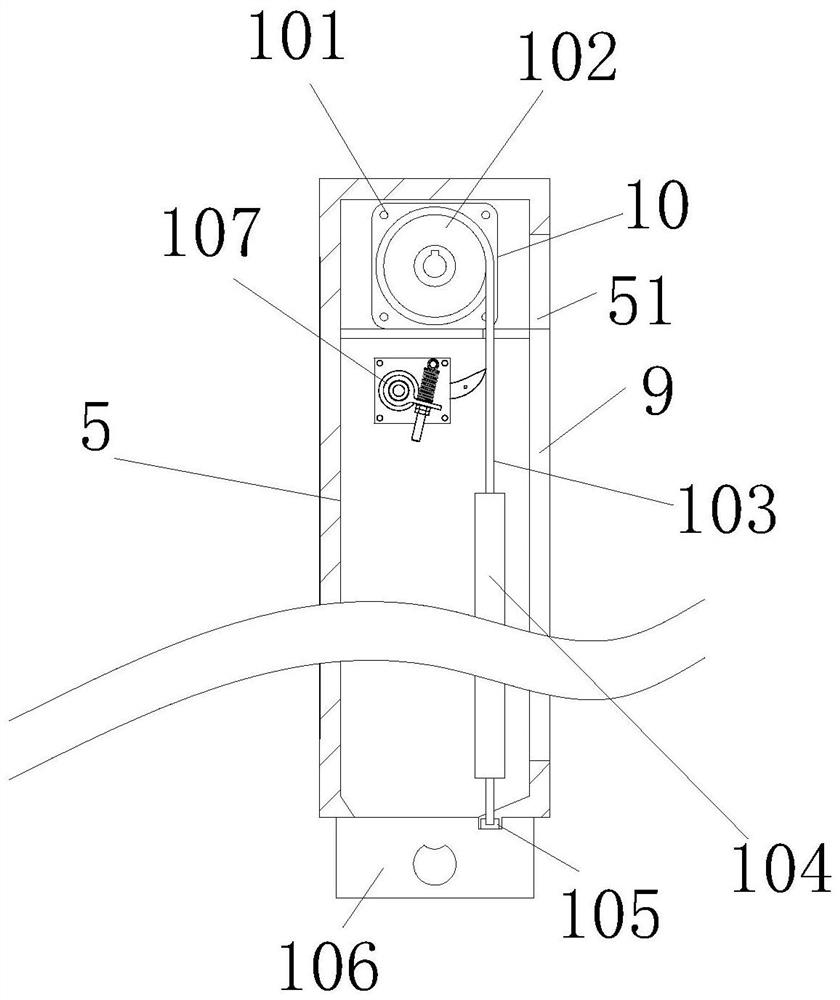

[0030] see image 3 , the present inve...

Embodiment 2

[0034]The present invention provides a dust cleaning device dedicated to the resistance load box through improvement. The scraper 1073 is arc-shaped, and the scraper 1073 is in contact with the left end of the blocking cloth 103, which is beneficial to scrape the dust from the upper end of the blocking cloth 103. , motor 101 and recovery roller 102 centerlines are perpendicular to the same horizontal direction, which is conducive to playing the role of making recovery roller 102 rotate smoothly.

[0035] The present invention provides a dedicated dust removal device for resistance load boxes through improvement, and its working principle is as follows;

[0036] First, before use, place the dust-cleaning device dedicated to the resistance load box horizontally, so that the fixing frame 1 can fix and support the device;

[0037] Second, when in use, connect the external power supply through the power lead 8 to provide power to the device, then press the button 7 on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com