Waste liquid container and liquid consumption apparatus

A storage body and waste liquid technology, applied in printing and other directions, can solve the problems of waste liquid tank hanging, waste liquid tank application, pin bending, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

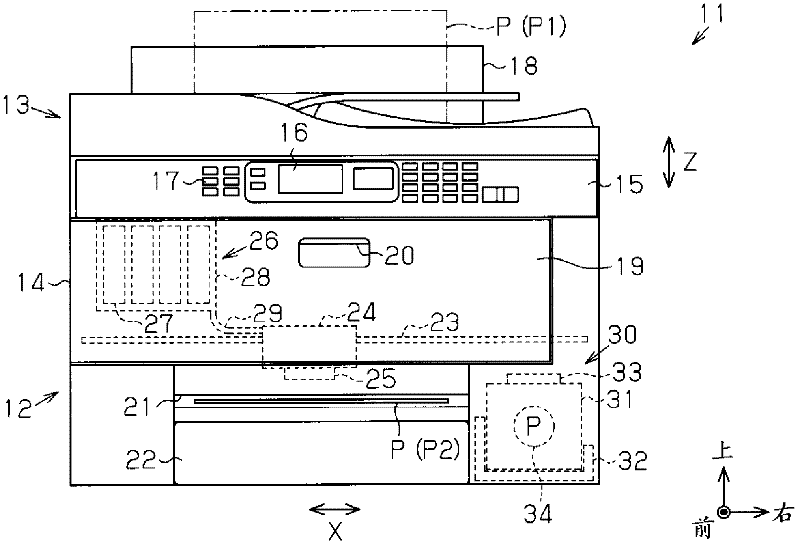

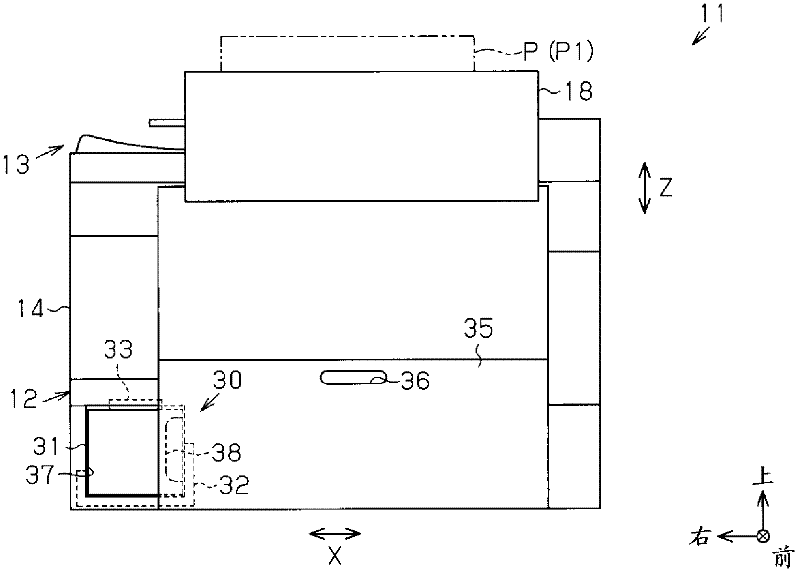

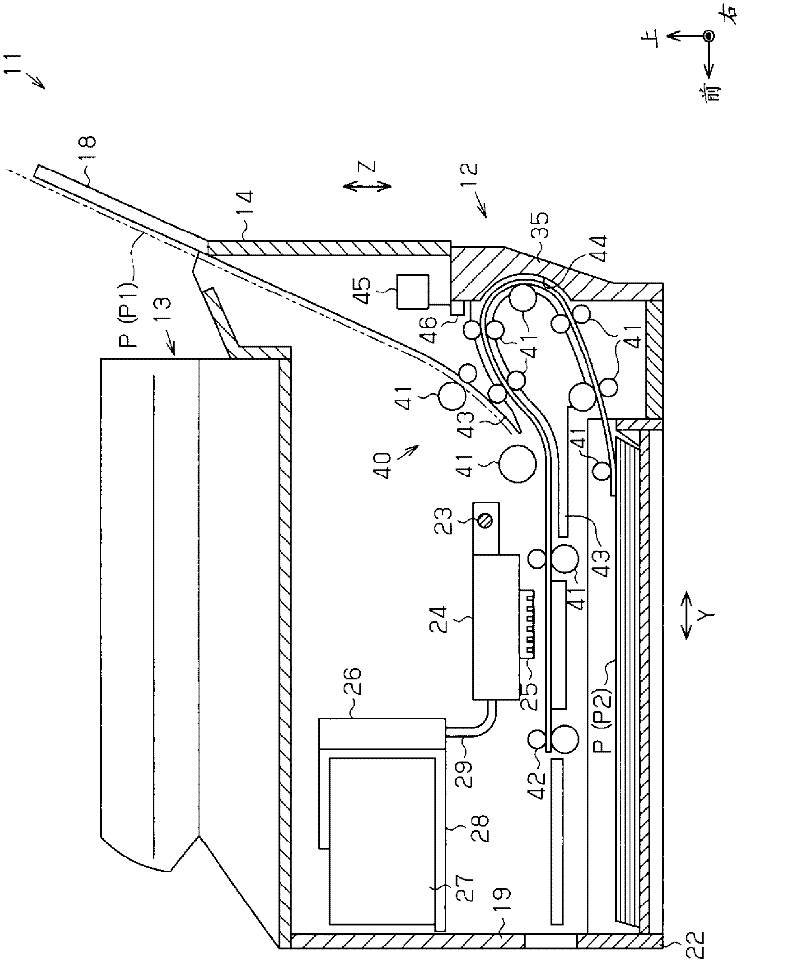

[0111] Hereinafter, an embodiment in which the present invention is embodied in a multifunction peripheral having the function of an inkjet printer will be described with reference to the drawings. In the following description, the "front-rear direction", "left-right direction", and "up-down direction" refer to the front-rear direction, left-right direction, and up-down direction indicated by arrows in the respective drawings. In addition, among the arrows showing upward, rightward, and forward in the drawings, a mark with a dot in the circle symbol (the figure of the front end of the arrow viewed from the front) means an arrow from the back of the paper toward the front, and the circle symbol The mark (the figure of the wing part of an arrow seen from the back) in which a cross is described in a symbol means the arrow which goes from the surface of the paper toward the quilt surface. In addition, the up-down direction is a vertical direction.

[0112] Such as figure 1 As sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap