Improved structure of printing head of thermal printer

A technology of thermal printers and print heads, which is applied in printing and other directions, and can solve problems such as complex assembly, short service life, and easy fall-off of print heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

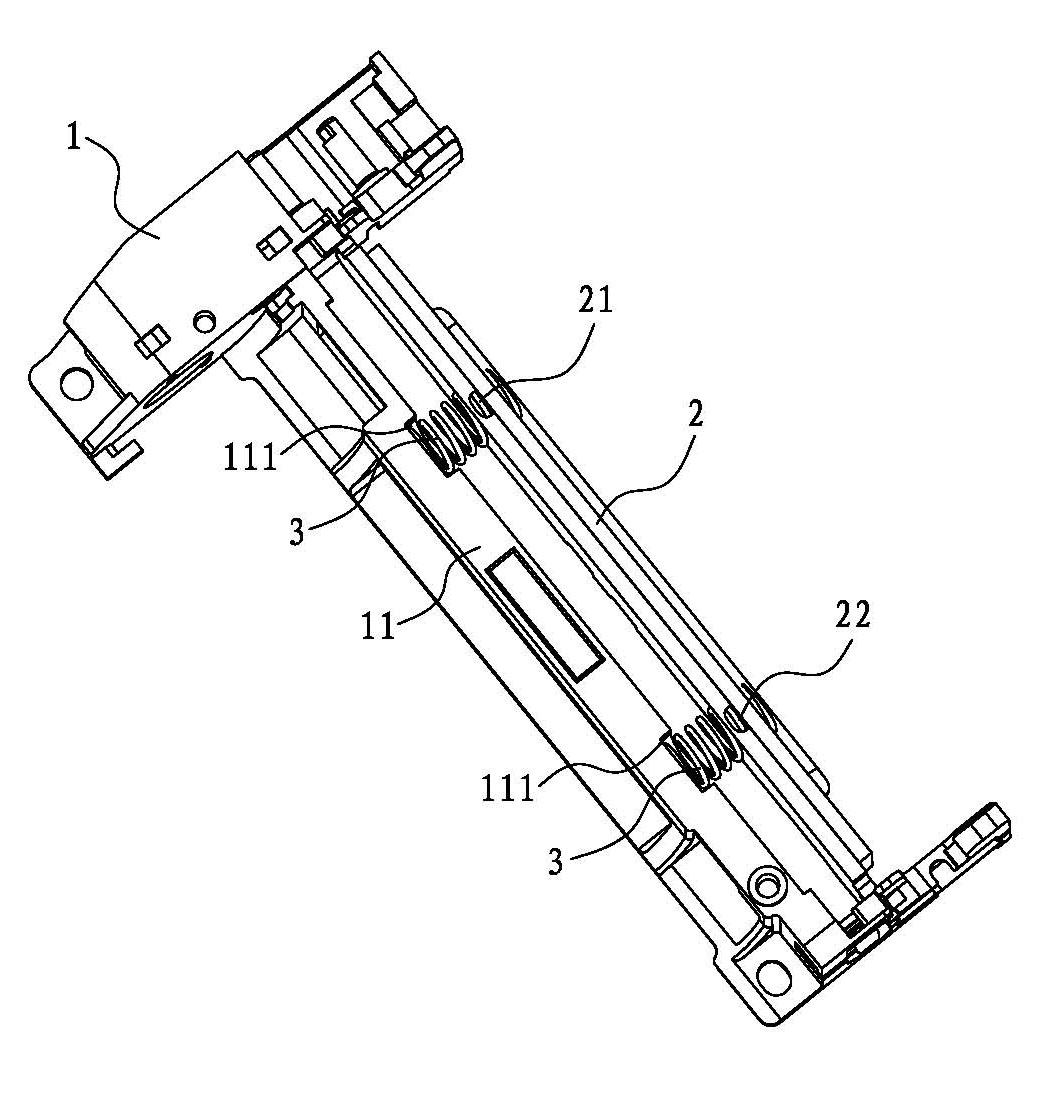

[0015] Such as figure 1 As shown, the present invention is an improved structure of a print head of a thermal printer, which includes a body 1, a mounting plate 2 and a spring 3.

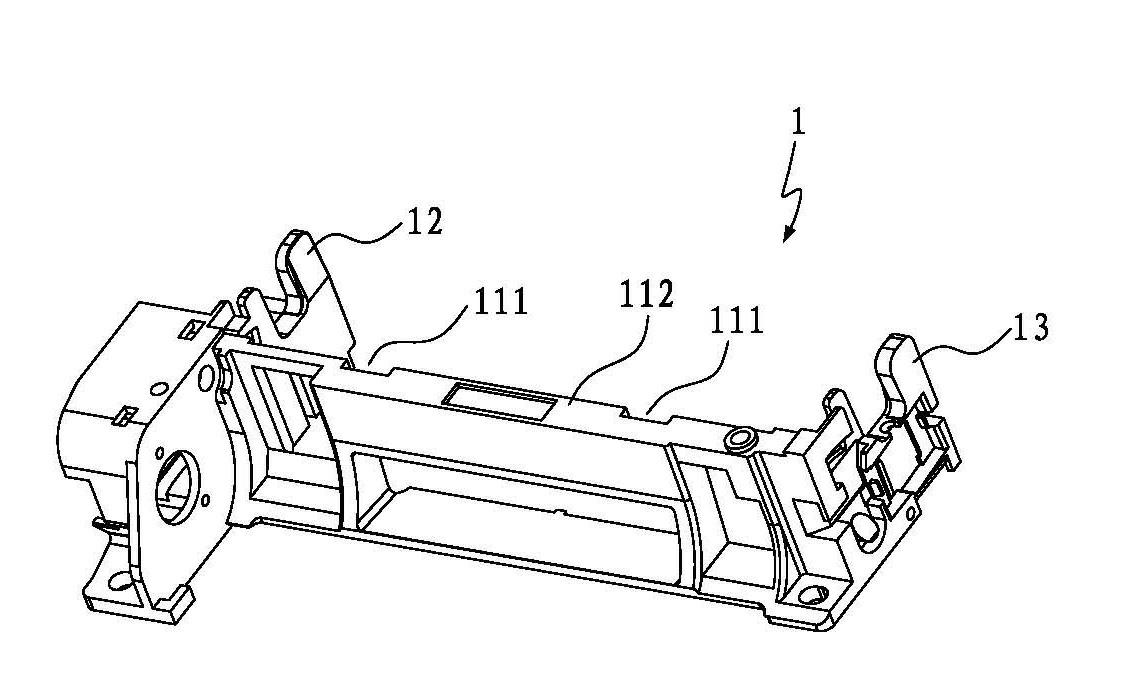

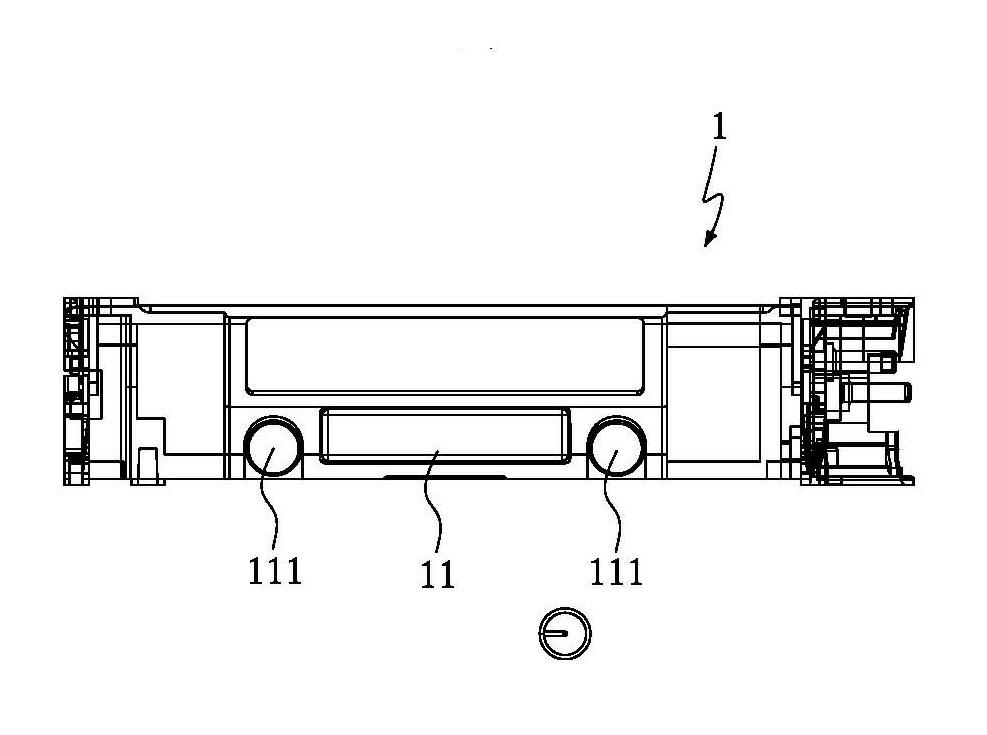

[0016] combine figure 2 , image 3 As shown, the body 1 has a spring mounting seat 11 and two cantilevers 12, 13, and the two cantilever arms 12, 13 extend vertically from both ends of the spring mounting seat 11 outwards. The two ends of the mounting plate 2 are interposed in the slots of the two cantilevers 12 and 13 of the body 1 . Two open slots 111 are provided on the spring mounting base 11, and the openings of the two opening slots 111 are located on the side wall 112 of the spring mounting base 11, so that the spring 3 can slide in through the openings during assembly.

[0017] The mounting plate 2 is provided with two protrusions 21, 22 for nesting the spring 3; one end of the spring is sleeved on the two protrusions 21, 22 and leans against the mounting plate 2, The other end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com