Mark printing manufacturing process based on transparent piece material

A technology of transparent sheet and manufacturing process, which is applied in printing process, printing, printing of special varieties of printed matter, etc. It can solve the problems of high manufacturing cost of logo printing, expensive mirror silver, no three-dimensional effect, etc., and achieves manufacturing cost. Low cost, stable and reliable logo color rendering, and reduced manufacturing cost of logo printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

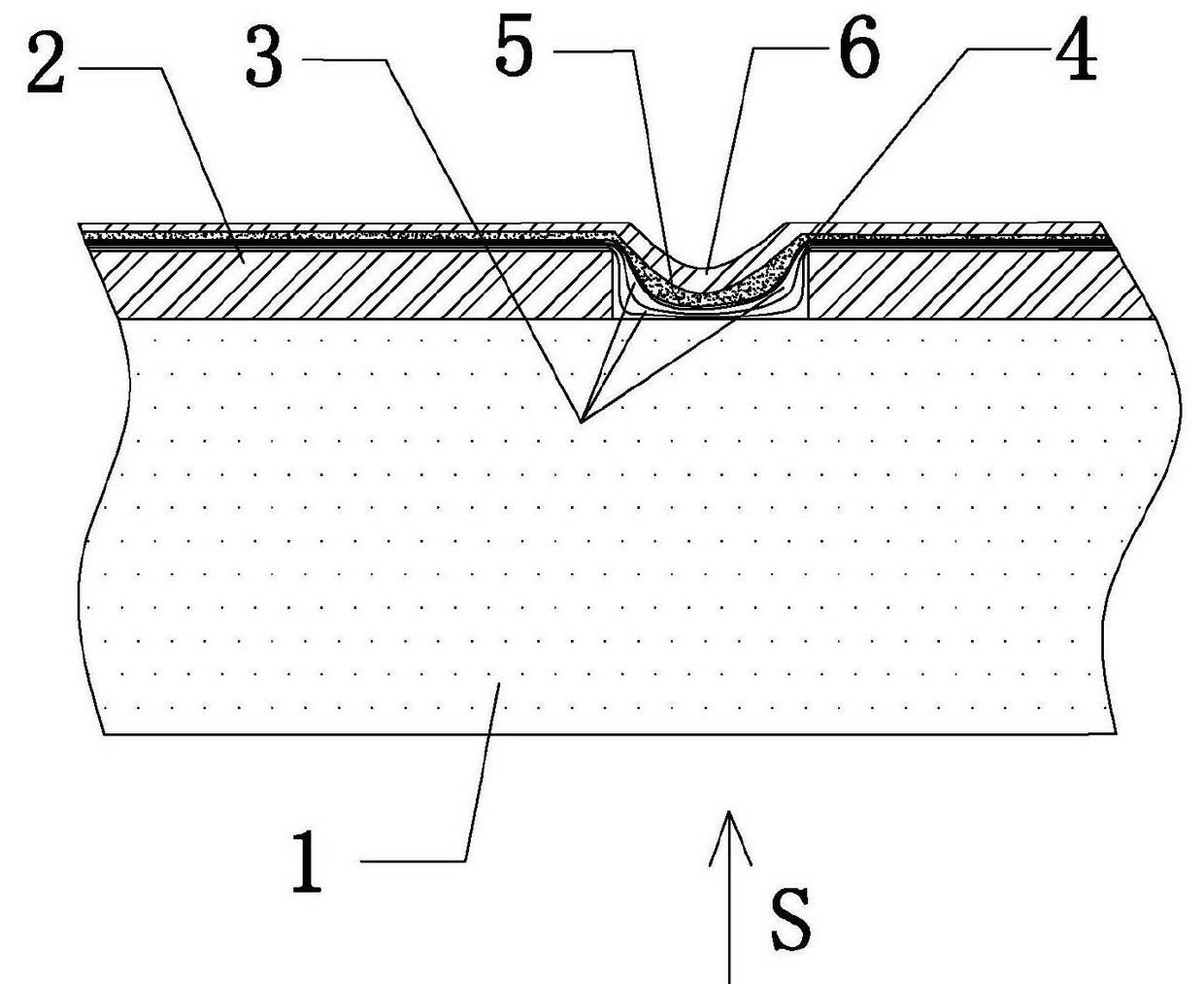

[0030] The three-dimensional logo printing manufacturing process based on transparent sheets includes the following process steps:

[0031] (1) Print a layer of black ink on some areas on the back of the transparent sheet (such as the border area of the transparent sheet), and the printing method can be screen printing; in order to highlight the information of the manufacturer (such as Lenovo, Samsung), etc., on the transparent sheet When printing black ink on the material, it is also necessary to reserve the manufacturer's logo (LOGO) part, and the logo (LOGO) part is not printed with black ink, that is, the logo is hollowed out; this step is the same as the existing technology;

[0032] (2) Print 2-5 layers of transparent ink on the marking part of the transparent sheet, preferably printing 3 layers of transparent ink; when printing 2-5 layers of transparent ink on the marking part, each stroke of the reserved mark will be smoothed Arc slot status (please refer to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com