Rubber rod clamp

A glue rod and beading technology, which is applied in printing, binding, etc., can solve the problems of piercing documents, high production costs, scratching human hands, etc., and achieve the effects of meeting environmental protection requirements, easy replacement, and eliminating edges and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

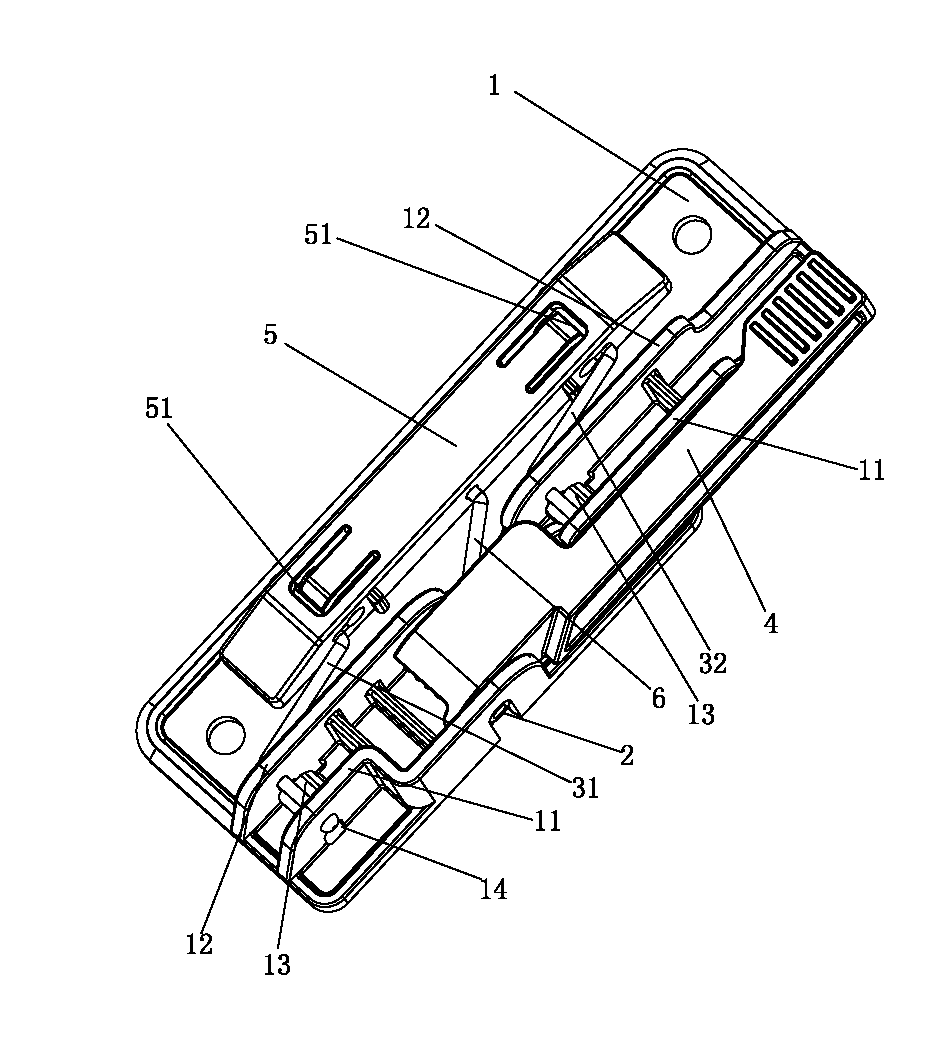

[0041] like Figure 1 to Figure 3As shown, a glue rod clamp includes a front arm 31, a rear arm 32 and a pin 2, and a base plate 1 made of plastic, a handle 4 and a bead 5, and the handle 4 is pivotally connected to the side of the base plate 1 through the pin 2. On the side 11, the pin 2 is covered with a torsion spring 6, and the first end and the second end of the torsion spring 6 are respectively connected to the bead 5 and the handle 4; Arm 31 and rear pivot arm 32 are respectively arranged on the both sides of torsion spring 6, and the first end and the second end of front pivot arm 31 are respectively movably connected to press bar 5 and base plate 1; To the outer surface of the press bar 5, and the first end of the front swing arm 31 is detachably connected with the press bar 5, the end of the second end of the front swing arm 31 stretches out to the outer surface of the side 11, and the second end of the front swing arm 31 The end is detachably connected with the sid...

Embodiment 2

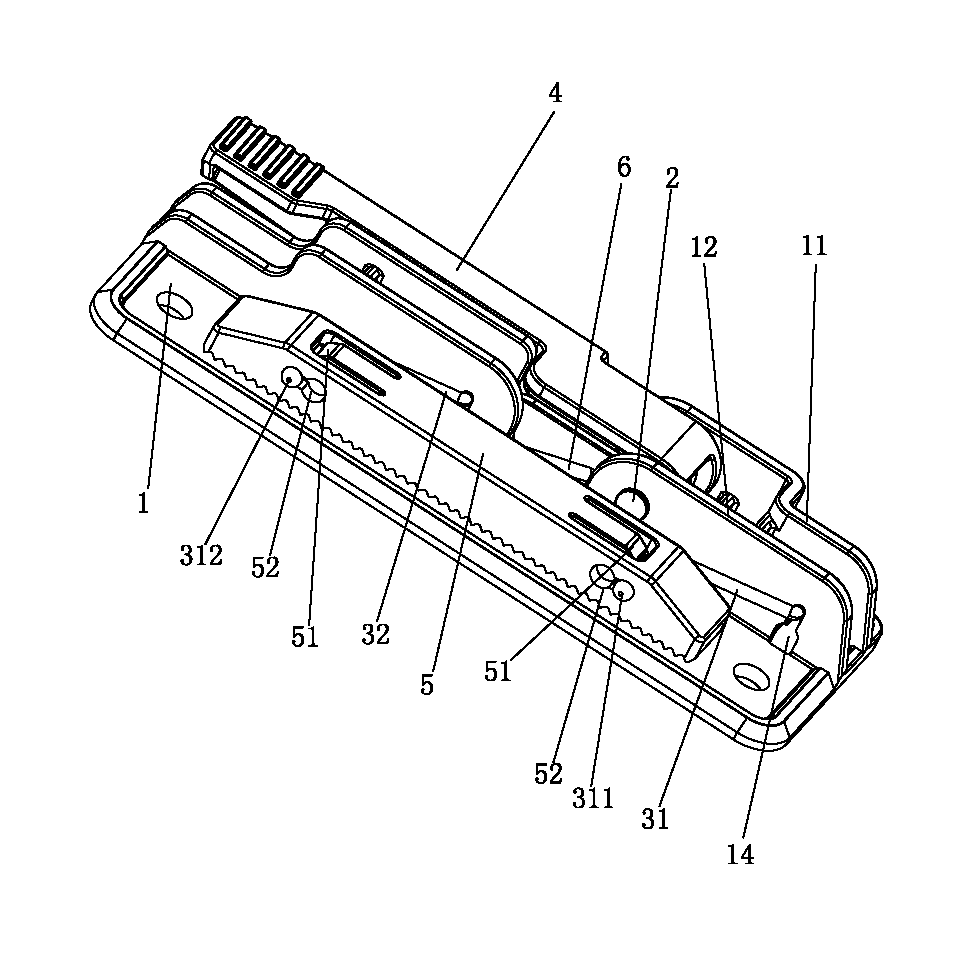

[0054] like Figure 4 to Figure 8 As shown, the difference between this embodiment and the first embodiment is:

[0055] Wherein, the side of the inner end of the bead 5 and the side of the outer end are respectively provided with a first T-shaped groove 52 for installing the first end of the front arm 31, and the first T-shaped groove 52 on the inner end of the bead 5 and the outer end of the bead 5 A shaft hole 7 is formed alternately at one end with a smaller width; the first end of the front pivot arm 31 is passed through the shaft hole 7 formed alternately by the first T-shaped groove 52 at the inner end and outer end of the bead 5 , and the front pivot arm 31 The first end of the first end is formed with a first abutment 311 of the front pivot arm, and the first abutment 311 of the front pivot arm abuts against the side of the outer end of the bead 5 . When assembling, the first abutment 311 of the front rotating arm at the first end of the front rotating arm 31 first p...

Embodiment 3

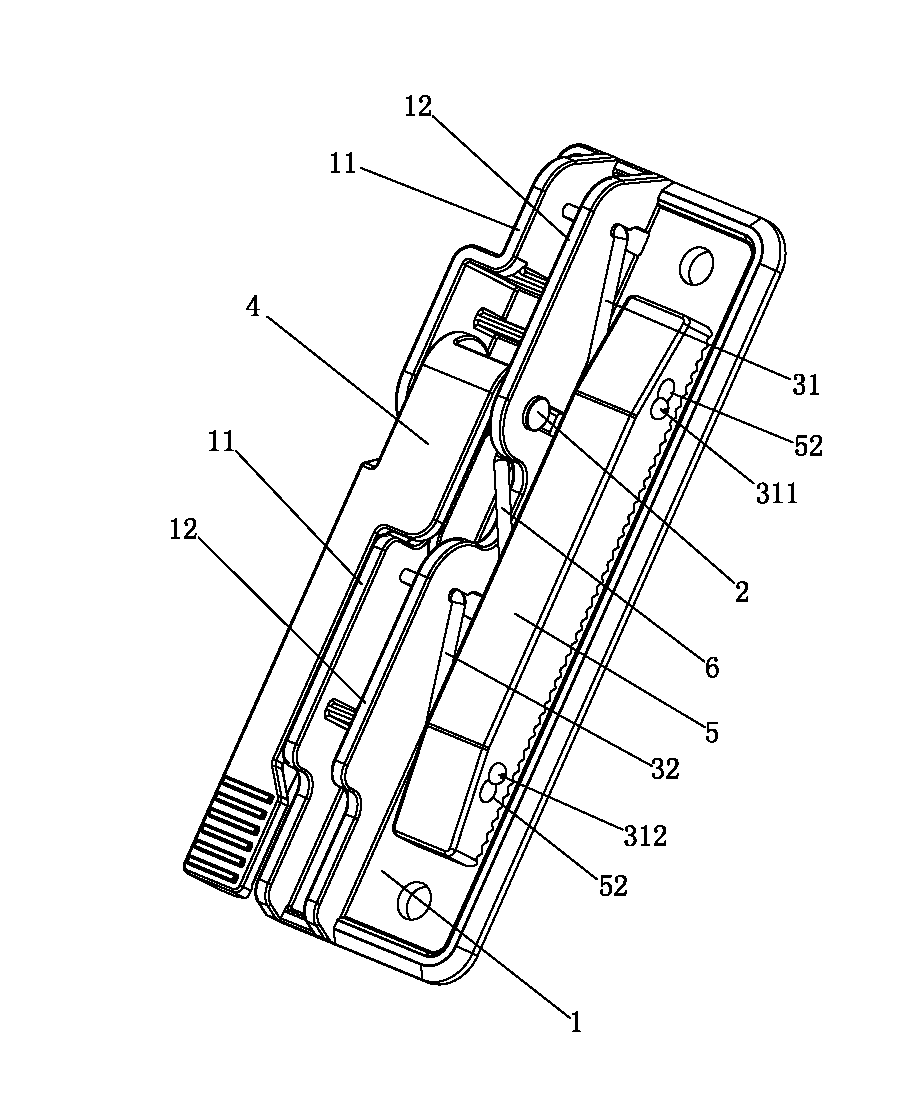

[0058] like Figure 9 As shown, the difference between this embodiment and embodiment one or embodiment two is:

[0059]Wherein, the side of the inner end of the press bar 5 is provided with a perforation 53 for the first end of the front swing arm 31 to pass through, and the side of the outer end of the press bar 5 is provided with a gap 54 for the first end of the front swing arm 31 to pass through, and This gap 54 penetrates the side surface of the outer end of the bead 5 and the top surface of the bead 5, and the first end of the front arm 31 passes through the perforation 53 of the inner end of the bead 5 and the breach 54 of the outer end of the bead 5, and the first end of the front arm 31 The end is formed with a first bending hook 312 of the front turning arm, and the first bending hook 312 of the front turning arm abuts against the side of the outer end of the bead 5 . During assembly, the first end of the front swing arm 31 passes through the perforation 53 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com