Holding and lifting device of large-scale passenger airplane mobile production line shifting equipment

A technology for mobile production lines and large passenger aircraft, which is applied to motor vehicles, transportation and packaging, etc., can solve problems such as high cost and complex mechanical structure control system, and achieve the effects of convenient control, good reliability and solving complex mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

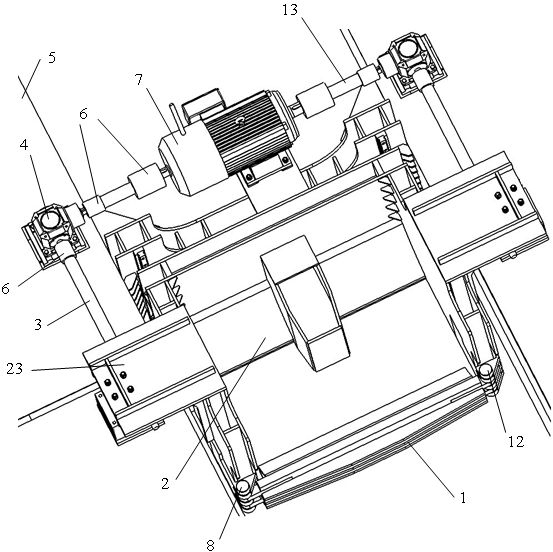

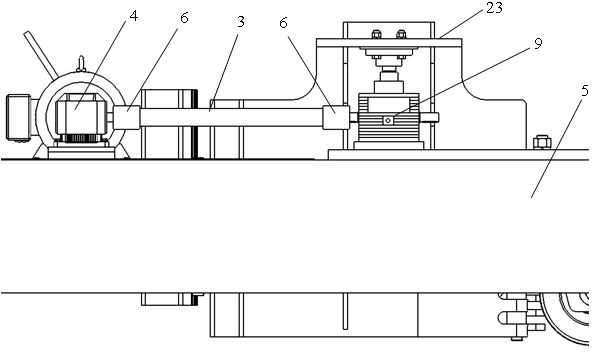

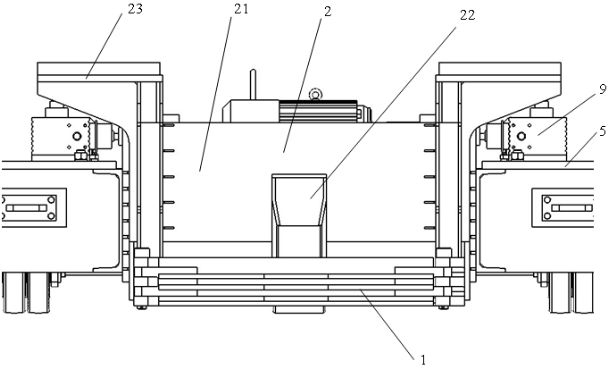

[0020] see Figure 1 to Figure 4 , a lifting device for large passenger aircraft mobile production line transfer equipment, including lifting front bracket 1, lifting frame 2, connecting shafts 3, 13, commutator 4, coupling 6, double output shaft motor 7, Elevator 9, sliding auxiliary guide rail 10 and slide block 11.

[0021] The front end of the lift frame 2 is open, and two supporting plates 23 protrude from the two side wings of the upper end. Rotate to enclose and affix the lift frame 2, which is locked and affixed by pin 12 to form an integral lift support bracket. The inner surface of the front bracket 1 and the inner surface of the rear end crossbeam of the lifting frame 2 are arc-shaped, and the two arc-shaped bottoms protrude forward, which is convenient for the front wheel of the front landing gear of the aircraft to be supported. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com