Driving device and its manufacturing method

A driving device and manufacturing method technology, which is applied in the direction of machines/engines, mechanical power generating mechanisms, mechanical equipment, etc., can solve problems such as disconnection, cumbersome operations, and concentration, and achieve the effect of reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

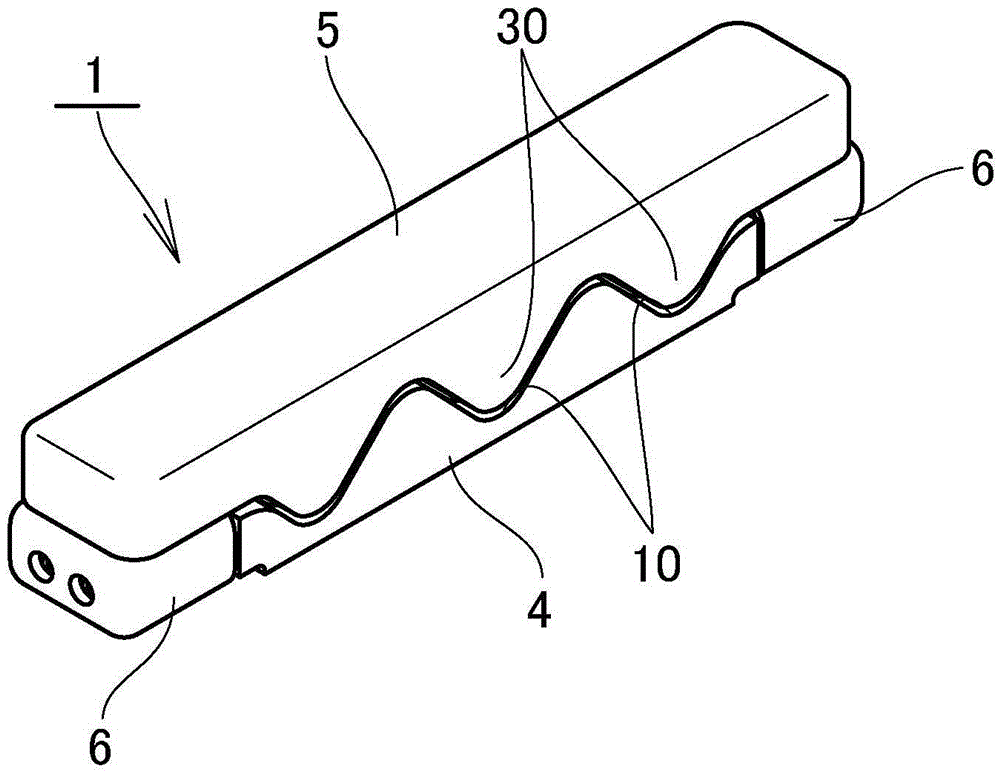

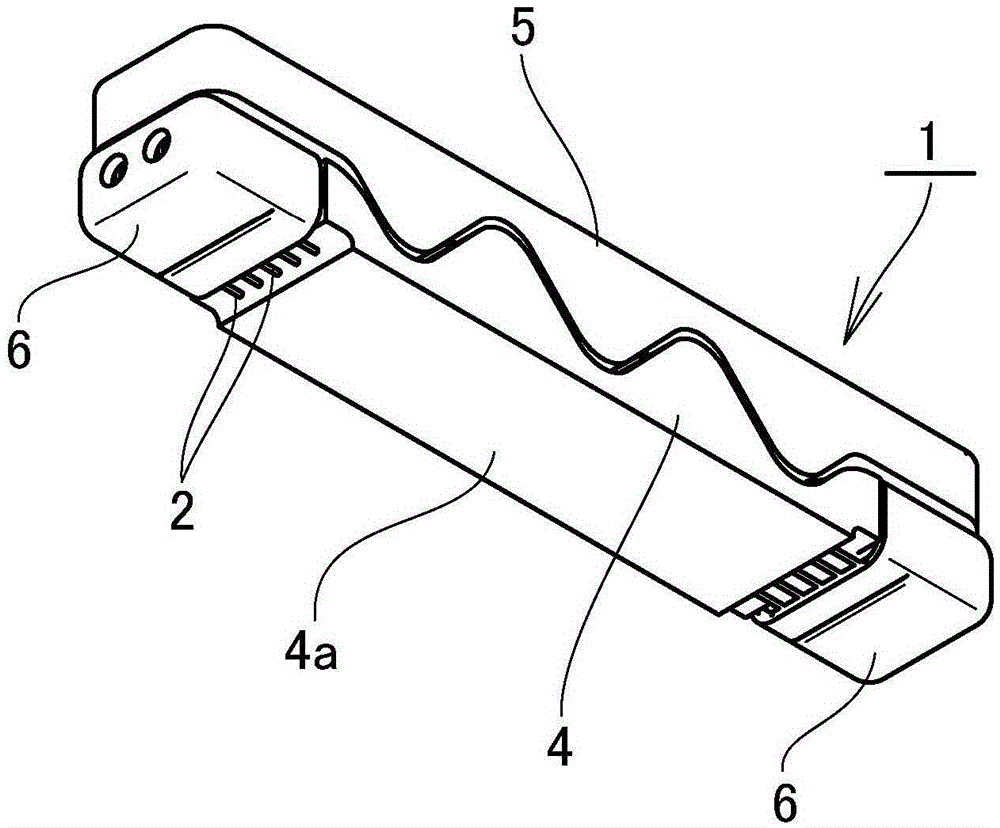

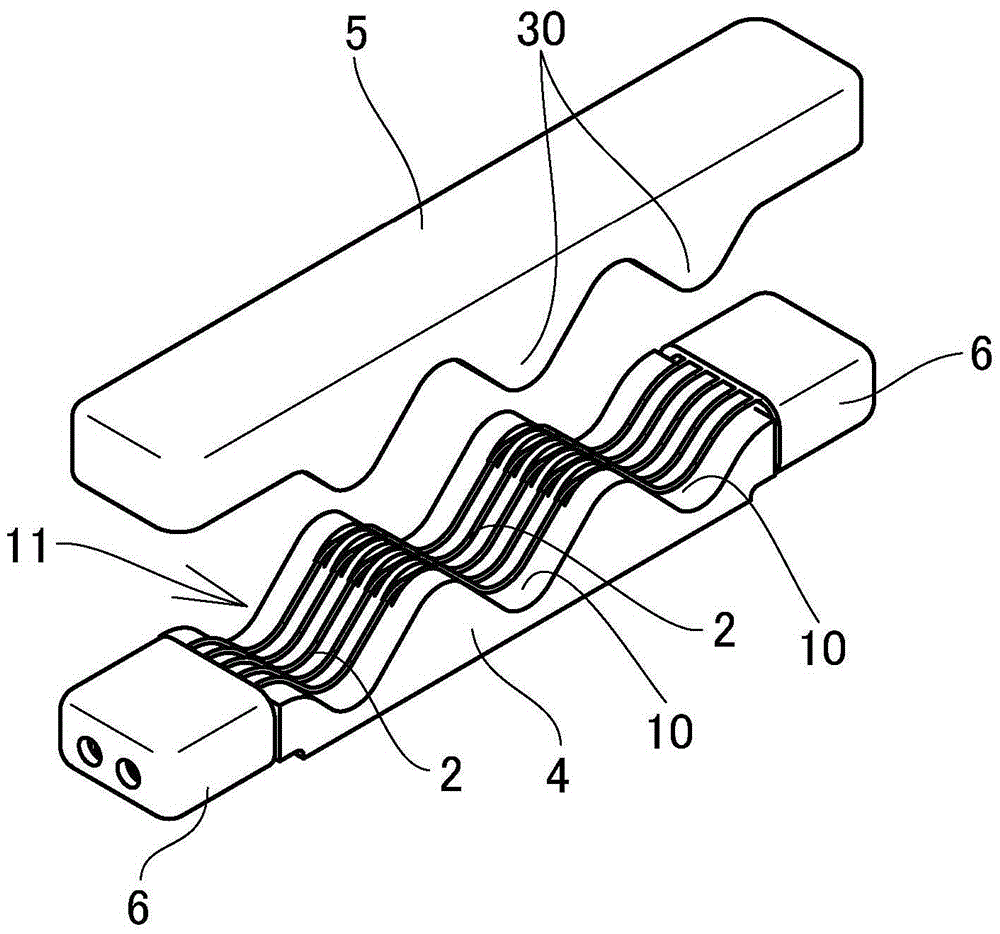

[0046] Next, based on Figure 1~Figure 10 The illustrated embodiment explains the implementation of the driving device of the present invention. Among them, the symbol 1 in the figure is a driving device, and the symbol A is a printed wiring board on which the driving device 1 is mounted.

[0047] The driving device 1 includes: linear shape memory alloy members 2, 2...; an insulating base member 4 having a fixing portion 3 for fixing the ends of the shape memory alloy members 2, 2...; and shape memory alloy members 2, 2 The movable member 5 moves relative to the base member 4 in conjunction with the shrinkage caused by the energization and heat; and the urging force is applied to the movable member 5 in the direction that the shape memory alloy members 2, 2... become the non-energized shape unit.

[0048] In addition, the drive device 1 is provided with terminal fittings 6 and 6 fitted with the fixing portion 3, and the bottom surface of the terminal fitting 6 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com