Combined type automatic feeding device for fiber adapter base

An optical fiber adapter, automatic feeding technology, applied in vibration conveyors, transportation and packaging, conveyors and other directions, can solve the problems of easy negligence, inability to meet production needs, automatic feeding bottlenecks, etc., to reduce manual labor, Improve the feeding efficiency and the effect of automatic feeding and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

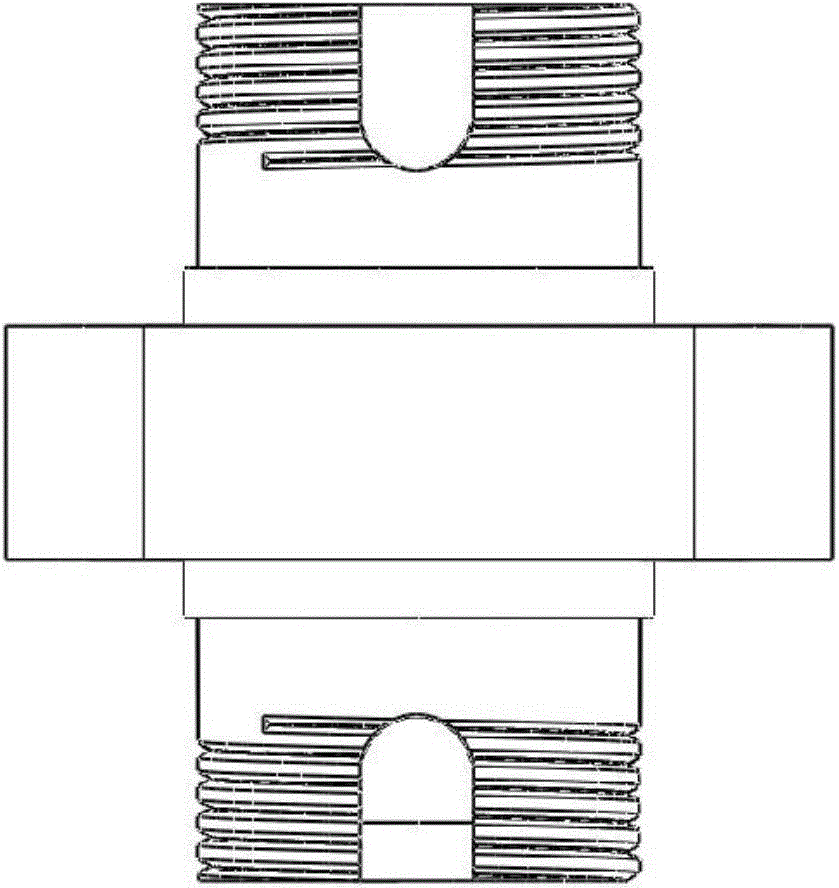

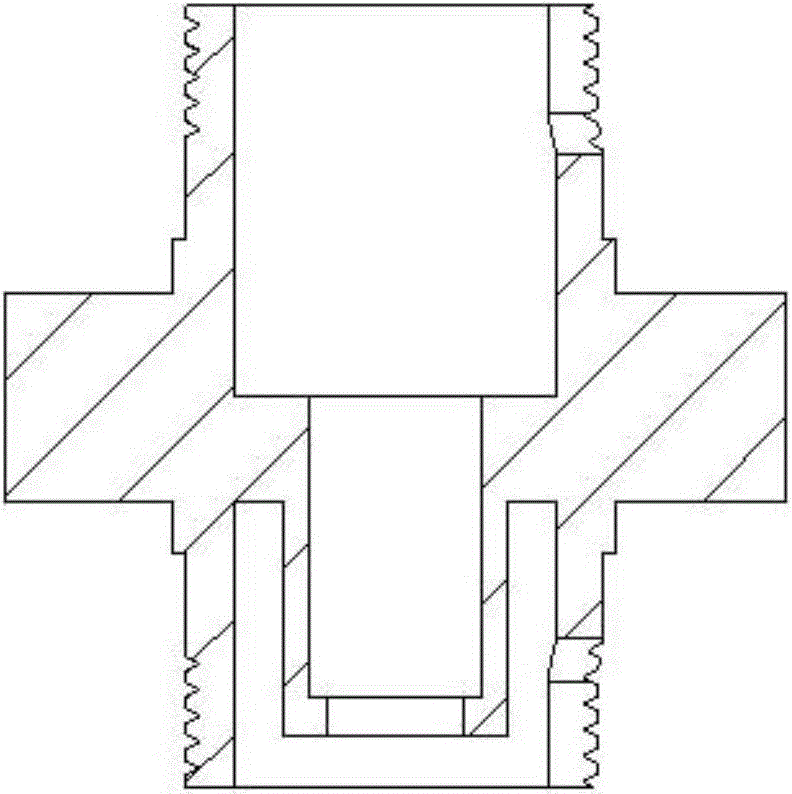

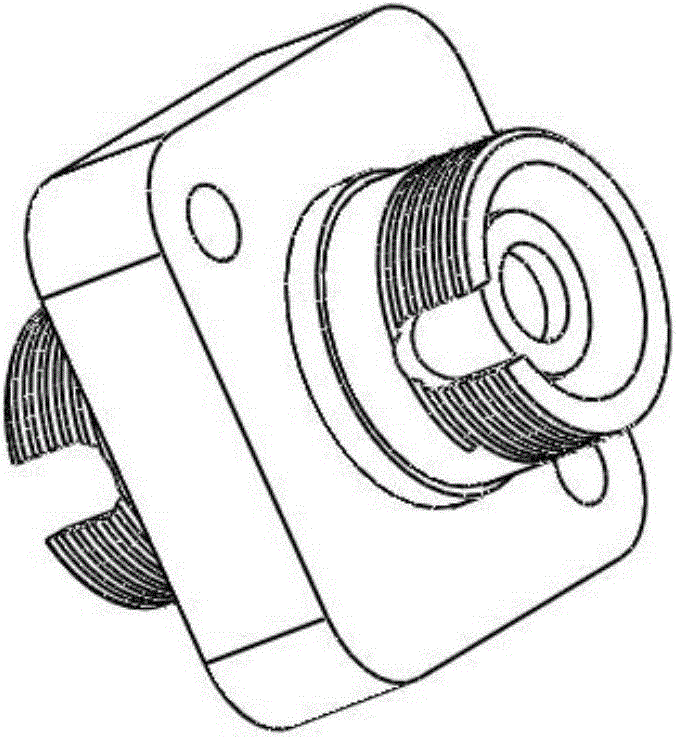

[0021] Front view, cutaway view, perspective view of fiber optic adapter base, such as figure 1 , 2 , As shown in 3, it has a large hole end and a small hole end, wherein the small hole end has an annular boss inside, and its small aperture is the inner diameter of the inner boss. Fiber optic adapter base composite automatic feeding device, such as Figure 4 As shown, it includes: vibration screening mechanism 1, jacking mechanism 2, opening and closing mechanism 3, road closing mechanism 4, vibration conveying mechanism 5 and frame 6. After the adapter base passes through the linear vibration screening mechanism 1, the jacking mechanism 2 transports the base to the opening and closing mechanism 3, and then gathers it to the road combining mechanism 4, and finally transmits it from the linear vibration conveying mechanism 5.

[0022] Vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com