Cooling wall for smelting furnace

A technology for smelting furnaces and staves, applied to furnace cooling devices, cooling devices, etc., can solve problems such as shedding, stave wear, and impact on service life, and achieve the effects of prolonging life, uniform slag hanging, and improving slag hanging conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

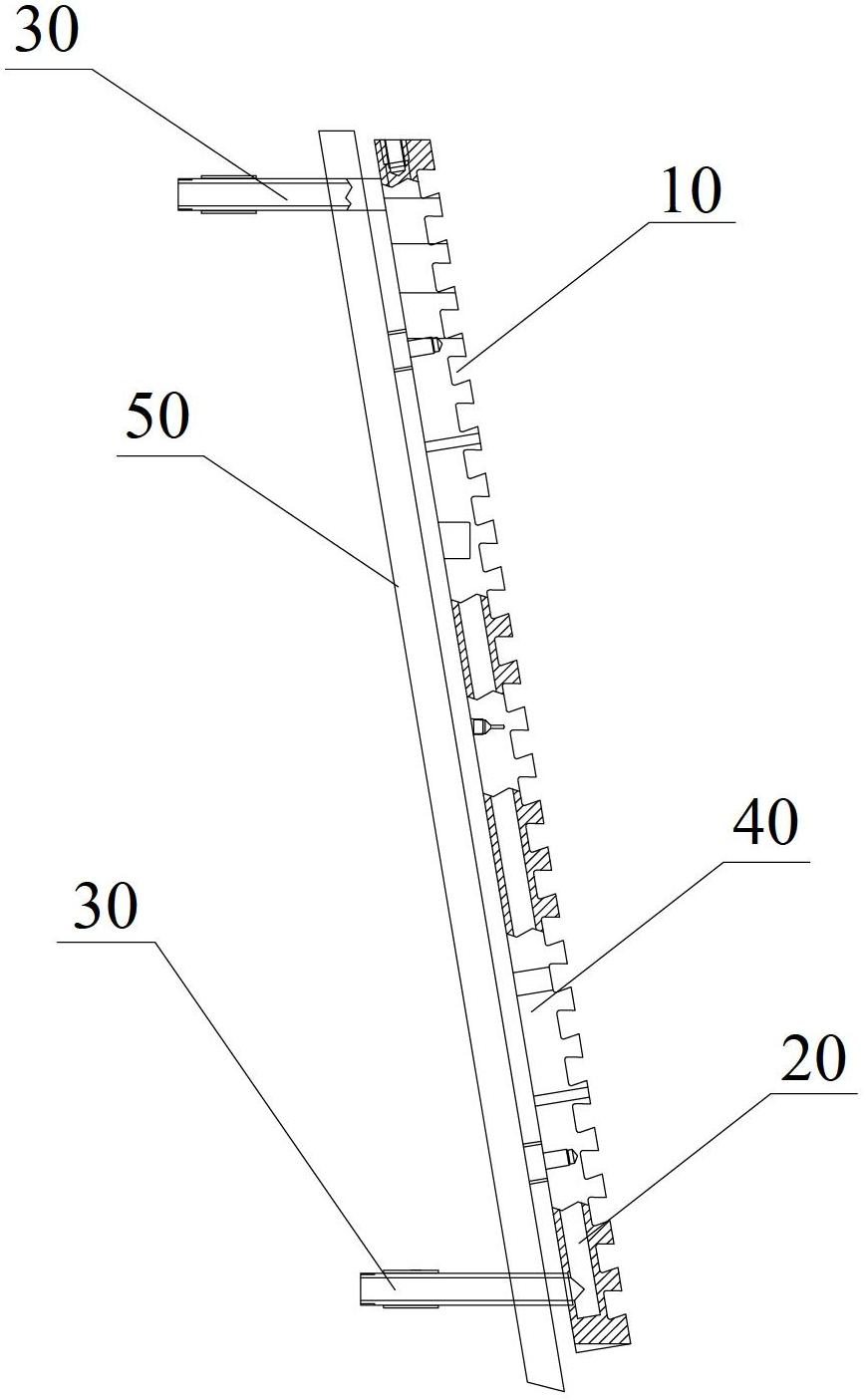

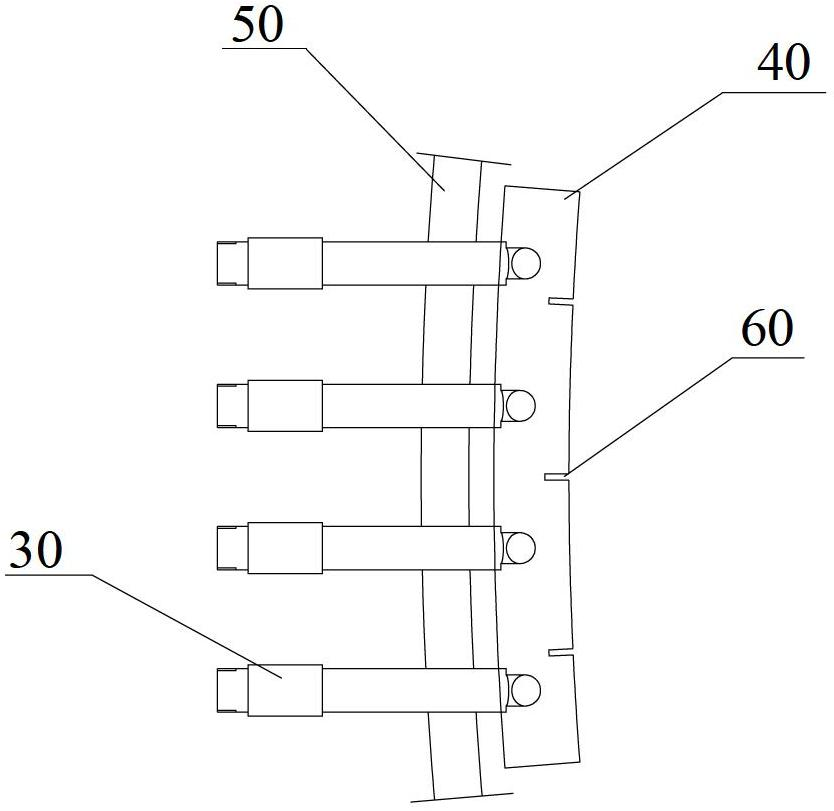

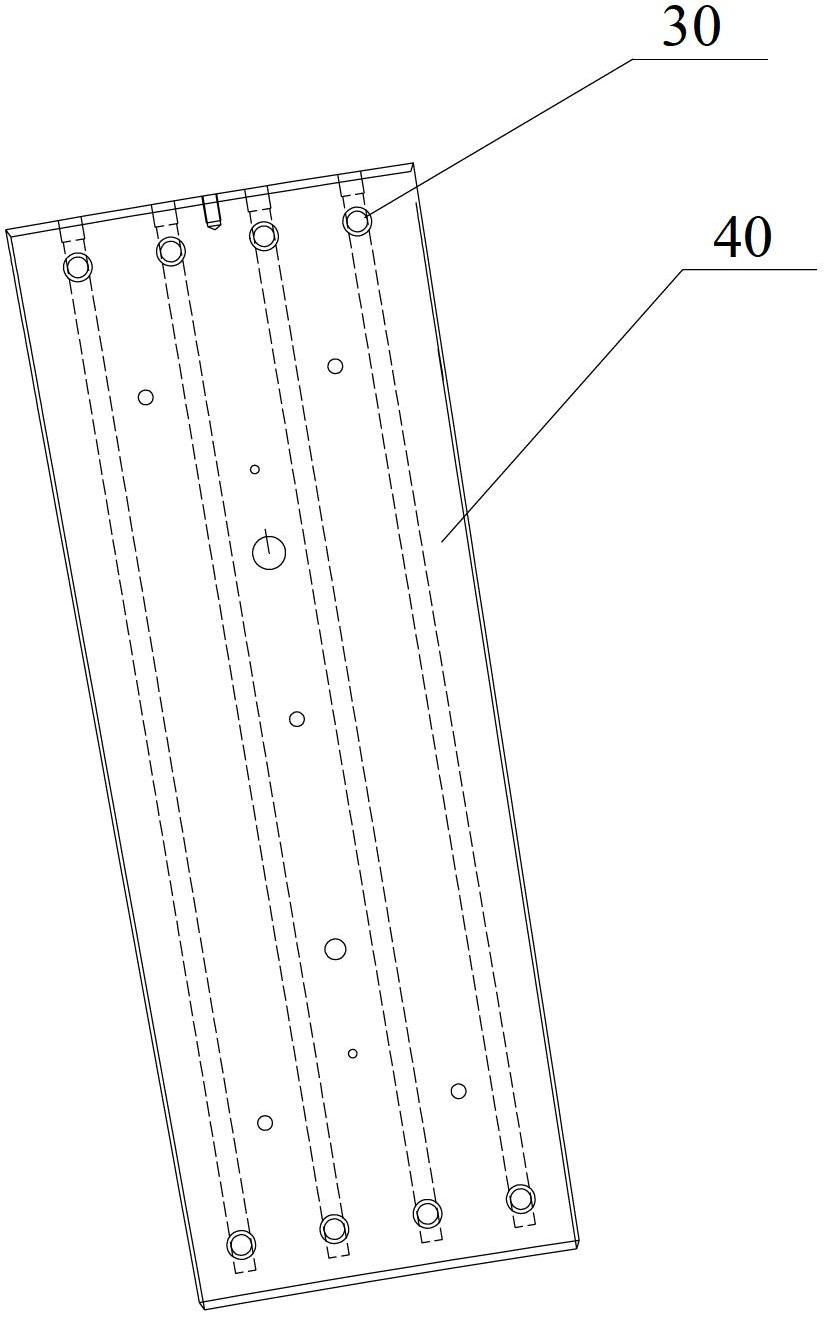

[0032] Copper staves are usually used to enhance cooling in areas with high heat loads in smelting blast furnaces, such as the bosh, waist and lower part of the furnace. Therefore the present invention corresponds to the different zones of the blast furnace, and the copper stave is made into a conical surface corresponding to the furnace shell ( Figure 1-4 in the first embodiment) or a cylindrical surface ( Figure 5-8 in the second embodiment). Below in conjunction with accompanying drawing, two typical forms of the present invention are described further.

[0033] Figure 1-Figure 4 shows the stave of the smelting furnace according to the first embodiment of the present invention. The staves in this embodiment are installed at the bosh positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com