Detachable anti-loosing component for screws

A technology for anti-loosening and screws, applied in the direction of screws, threaded fasteners, nuts, etc., can solve problems such as difficult disassembly, and achieve the effect of simple assembly and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

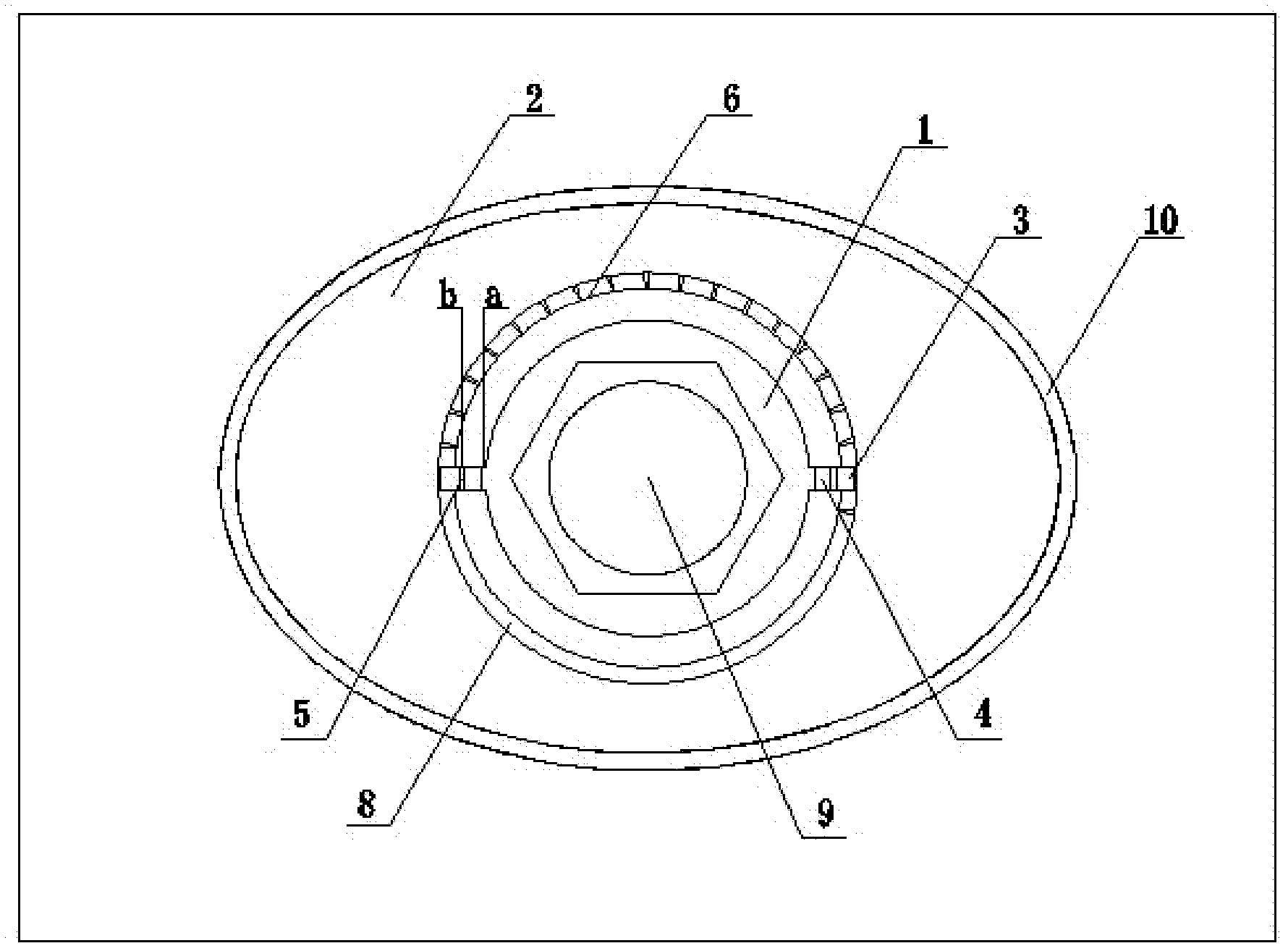

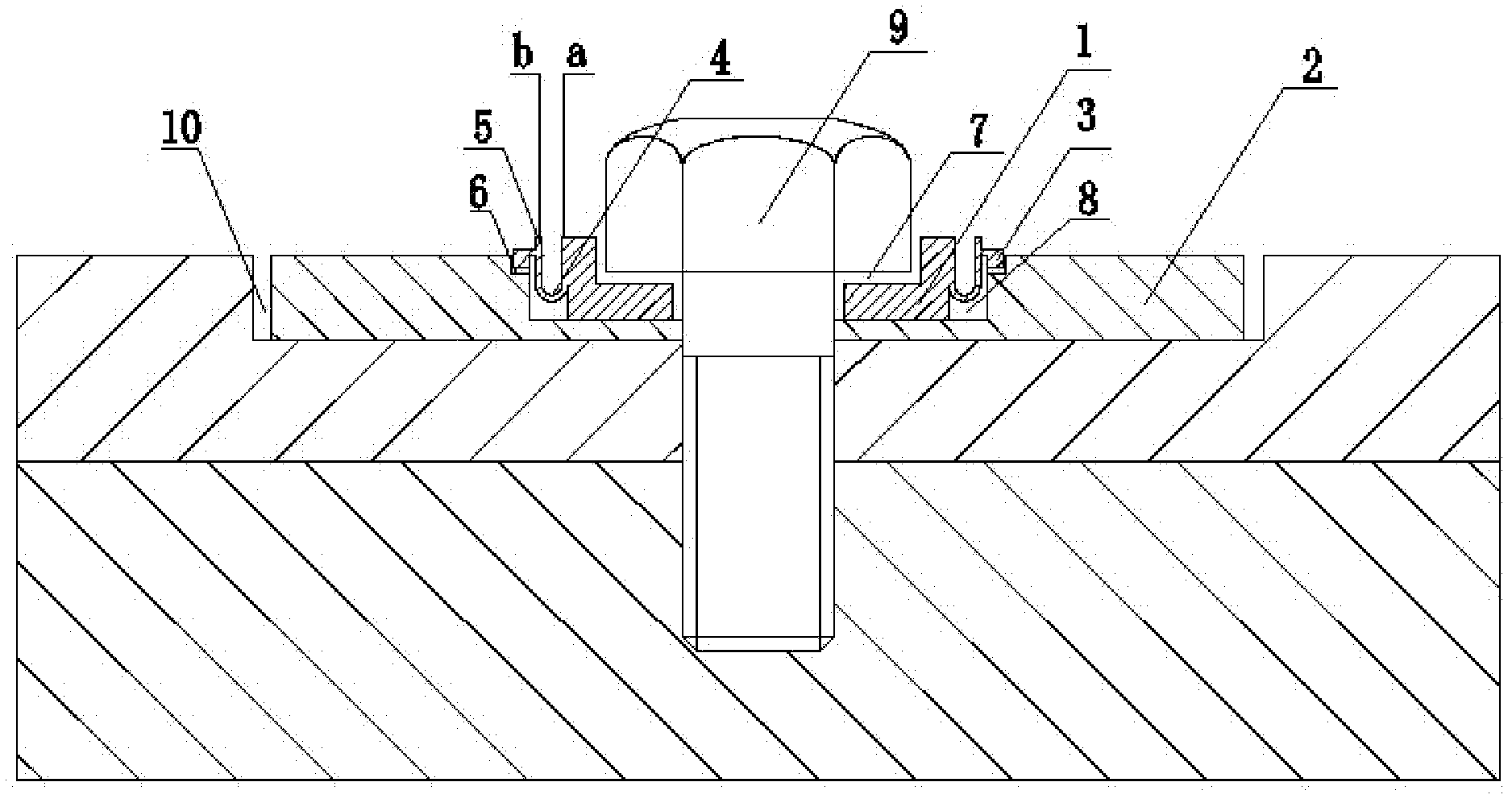

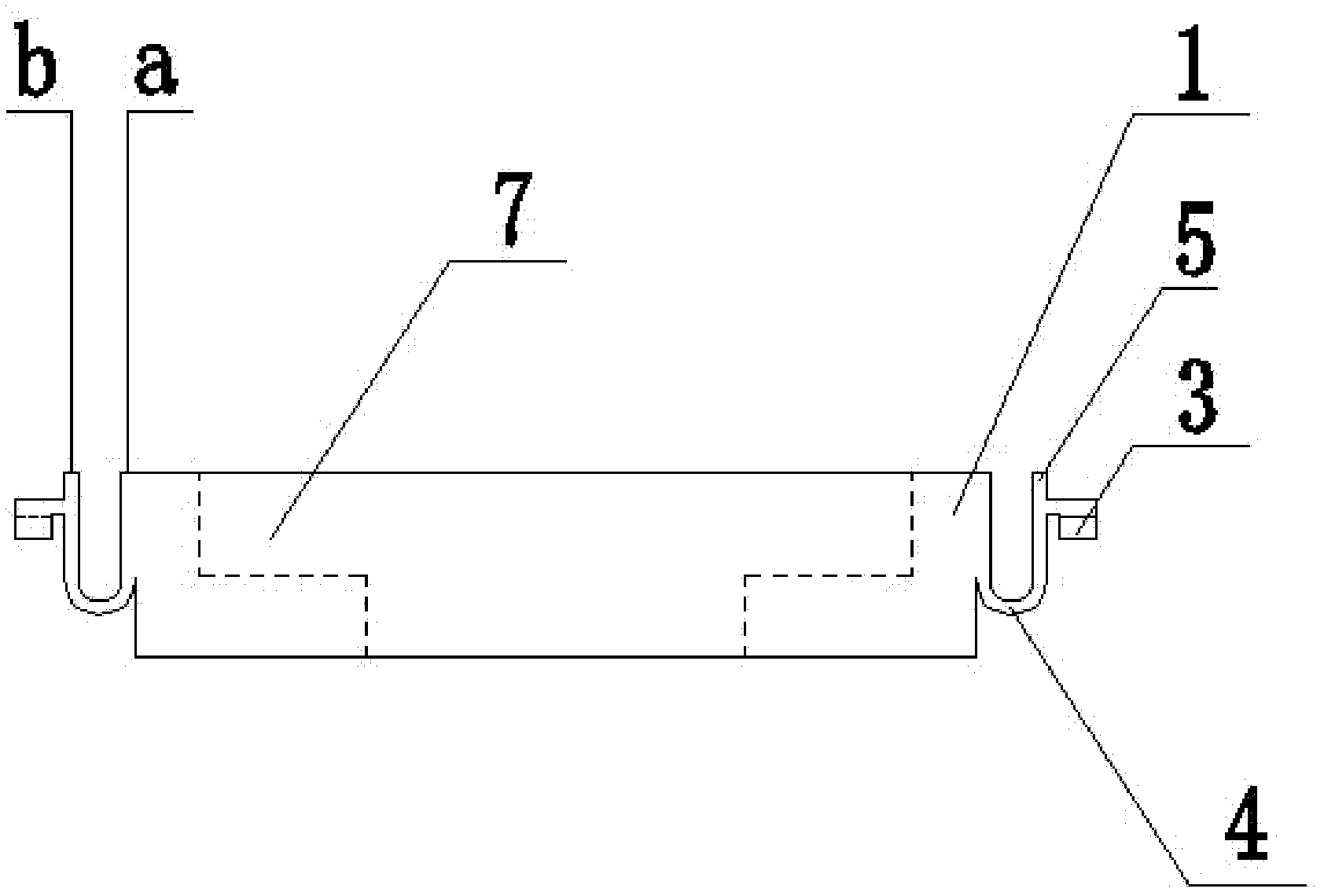

[0018] as attached figure 1 Shown is the detachable screw anti-loosening assembly of the present invention, which includes a connecting plate, a main locking member 1, a secondary locking member 2, a main locking tooth 3, an elastic arm 4, a dial block 5, a secondary locking tooth 6, and a positive six Hexagonal counterbore 7, circular counterbore 8, screw 9; The main locking piece 1 is cylindrical, and the upper surface of the cylinder is provided with a regular hexagonal counterbore 7 (see attached image 3 ), the center line of the regular hexagon coincides with the axis of the cylinder; on the outer peripheral wall of the main locking member 1, there are two locking component groups at the position with the largest radial distance, and each locking component group contains the main Locking tooth 3, elastic arm 4, shifting block 5, wherein the elastic arm 4 is U-shaped, its a end is connected on the outer peripheral wall of the main locking member 1, and the b end of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com