High-performance electrical isolation flange device resisting high temperature and high pressure

A high-performance, high-temperature-resistant technology, applied in the direction of flange connection, heat preservation, pipes/pipe joints/pipe fittings, etc., can solve the problems of high-temperature and high-pressure fluid leakage, insulation, loss of sealing effect, and insulation failure of insulating gaskets. The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

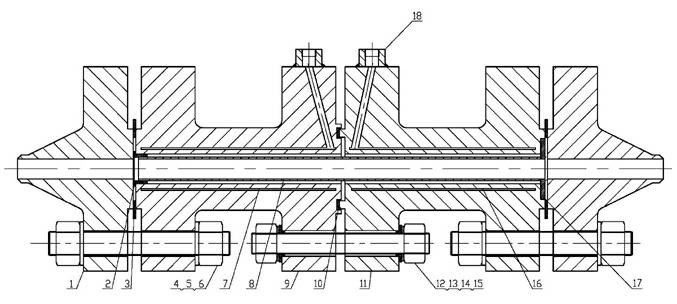

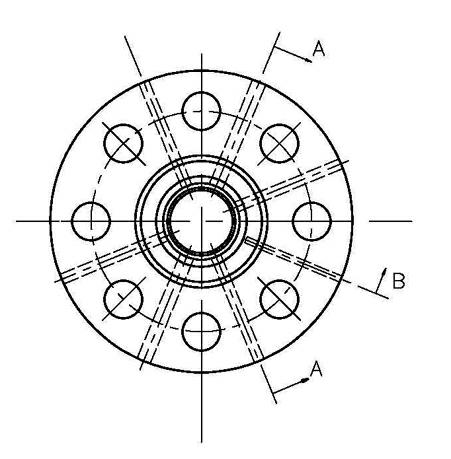

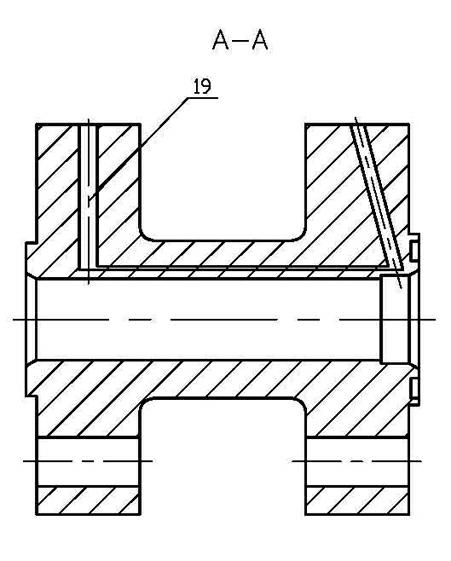

[0027] see figure 1 And Fig. 2, a kind of high-temperature and high-pressure-resistant high-performance direct-current insulating flange device of the present embodiment comprises a pair of necked pressure-bearing flanges 1 and a pair of insulating pressure-bearing flanges 9, between the insulating pressure-bearing flanges 9 The tenon and groove surfaces are connected to each other, and the asbestos mat 10 is used for insulation between the tenon and groove surfaces. The insulating pressure-bearing flange 9 is provided with a cooling water flow channel near the asbestos mat 10. The cooling water flow path includes two cooling water inlets 18 and two cooling water outlets. 19 and the channels 7 and 16 between the two, the asbestos pad 10 can be cooled by the cooling water flowing through the cooling water channel next to it, so as to ensure that the asbestos pad 10 can be used in a lower temperature range; the pressure-bearing flange with neck The bolt structure is adopted, spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com