Laser diffraction type multi-system axis parallelism detecting device

A parallelism detection and laser diffraction technology, which is used in weapon testing, weapon accessories, offensive equipment, etc., can solve the problems of time-consuming and laborious, and keep still, and achieve the effect of clear imaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

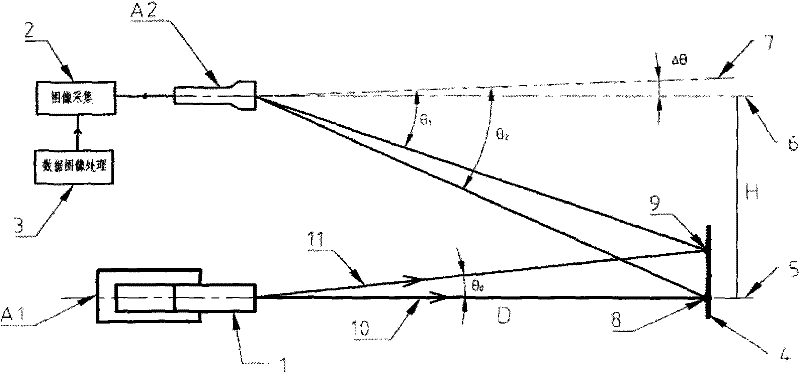

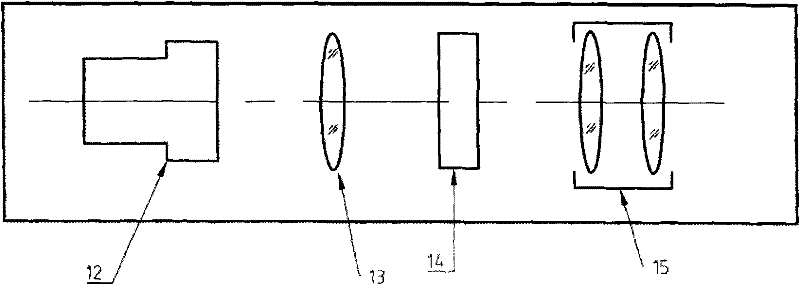

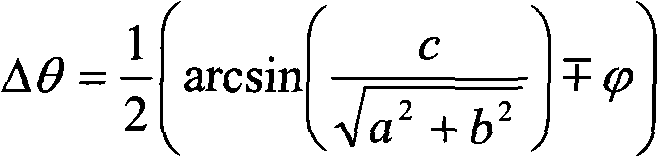

[0011] figure 1 It is a schematic diagram of the principle of the present invention, and the included angle of emission from device 1 is θ 0 Two beams of laser light 10, 11, wherein the direction of the laser beam 10 represents the axis 5 of the platform A1, and the two beams of laser light are projected onto the reflective screen 4 at a distance D to form bright spots 8, 9, which are diffusely reflected by the reflective screen and then The television observation device on platform A2 detects and images. The baseline distance between platform A1 and platform A2 is H. The position of the TV electric cross represents the axis position of the TV detector, and it is also the reference center when measuring. When platform A1 is parallel to platform A2, the axis, that is, the electric cross, is 6. When it is not parallel, assume that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com