Novel water-proof structure for LED display panel

A technology of LED display panel and waterproof structure, which is applied in the direction of chassis/cabinet/drawer parts, instruments, identification devices, etc. The problems of high rate, man-hour and material cost are high, and the effect of low cost, easy font mode and easy structural assembly is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

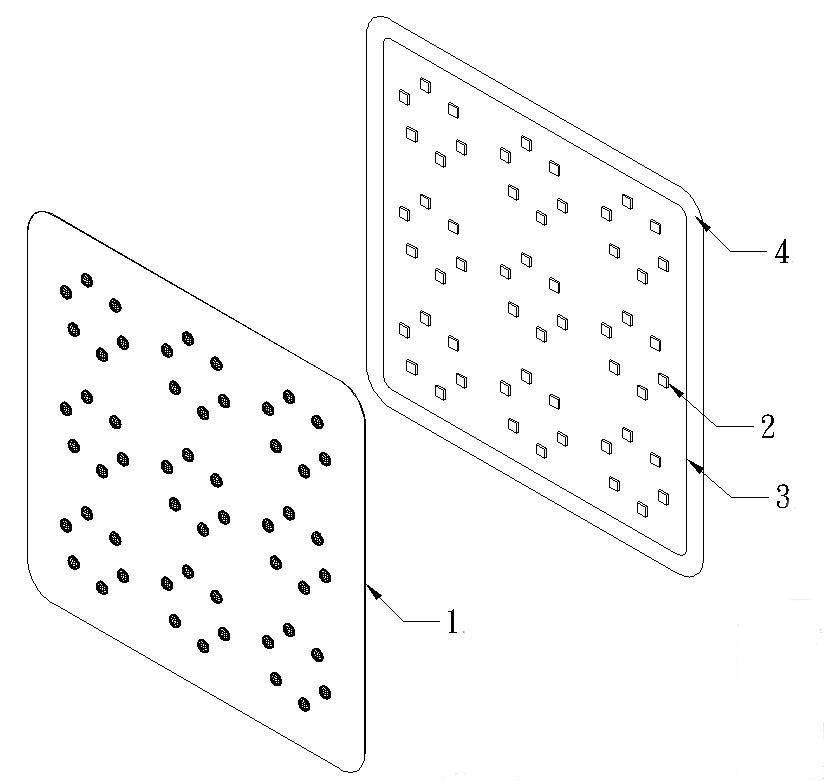

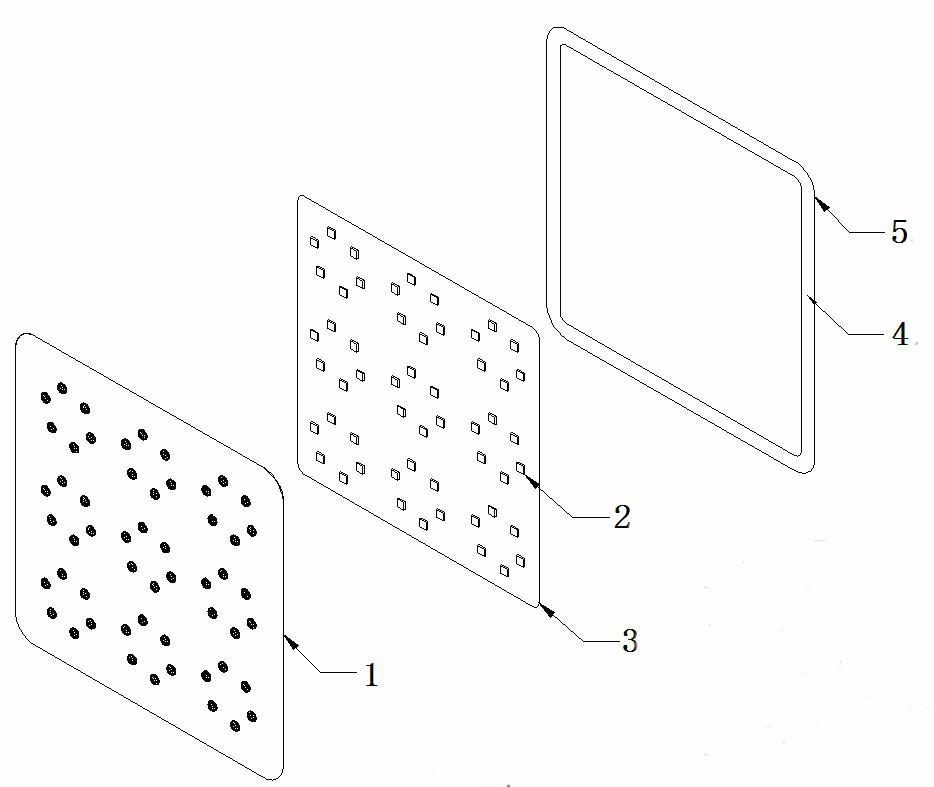

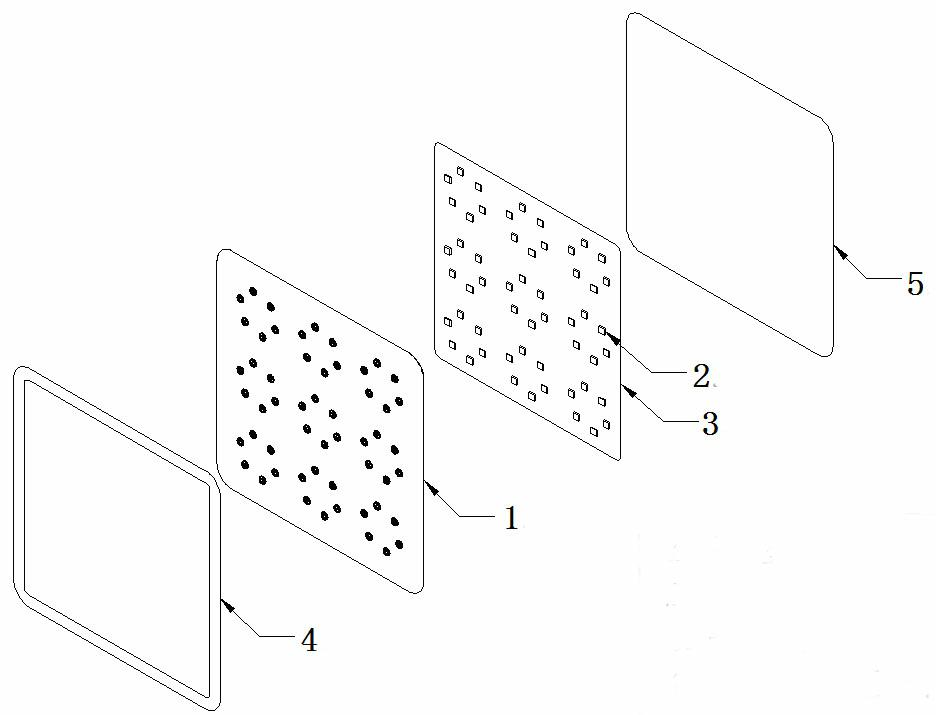

[0023] Embodiment 1: As shown in the figure, this structure is composed of plastic shell 1, LED 2, circuit board 3, pressing parts 4 and back plate 5. Plastic shell 1 is made of transparent plastic shell, and the plastic shell is made by vacuum forming, which can make large The surface area of the board completely covers the LED2 and the circuit board 3, replacing the transparent cover of the LED. At the same time, the emission angle of the LED 2 only needs to be selected from a different LED 2. The vacuum forming mold is much cheaper than the plastic injection mold, and can be produced at the same time. Large area circuit board 3 boards, 300cm x 900cm.

[0024] The transparent plastic shell is made of PET (2. polyethylene terephthalate polyethylene terephthalate), a material with good weather resistance. At the same time, the thickness of the plastic shell 1 depends on the size of the circuit board 3 and the shape of the LED 2. Different thicknesses from 0.3mm to 1.5mm can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com