Bipolar plate membrane electrode assembly

A bipolar plate and membrane electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low pure oxygen and can not meet the requirements, and achieve the effect of increasing the assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0034] Specific embodiment one, see Figure 5 An anode encapsulation groove 17 is arranged around the anode gas diffusion layer 12 and the anode catalyst layer 13 of the encapsulated membrane electrode 3 , and the anode encapsulation groove 17 is encapsulated by an adhesive 18 .

specific Embodiment 2

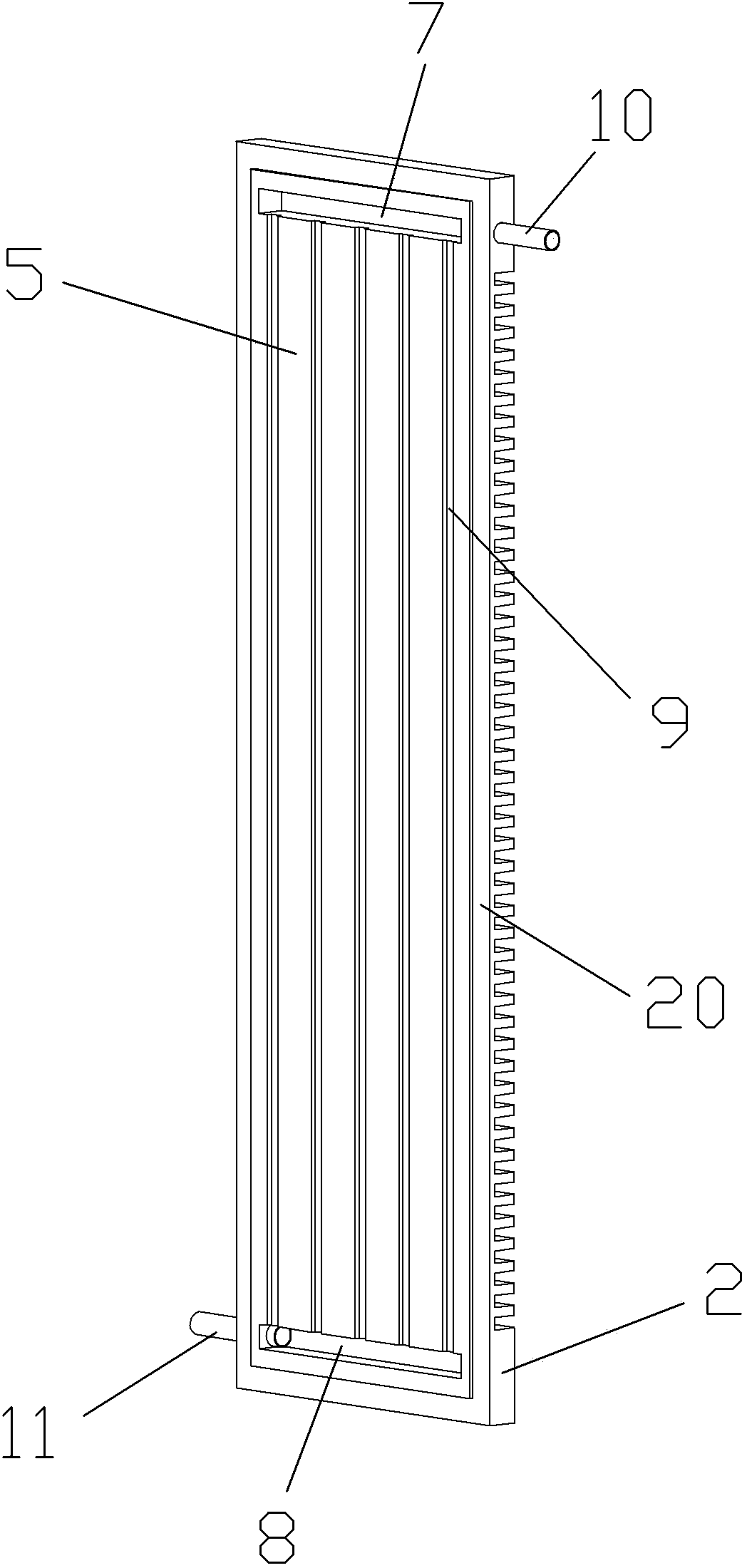

[0035] Specific embodiment two, see Image 6 :

[0036] The anode gas diffusion layer 12 and the anode catalytic layer 13 of the packaged membrane electrode are provided with an inner anode packaging groove 19 around, and an outer anode packaging groove 20 is arranged around the anode surface 5 contacting the anode gas diffusion layer 12, and the inner anode packaging The groove 19 and the outer anode packaging groove 20 communicate with each other to form an integral anode packaging groove 17 .

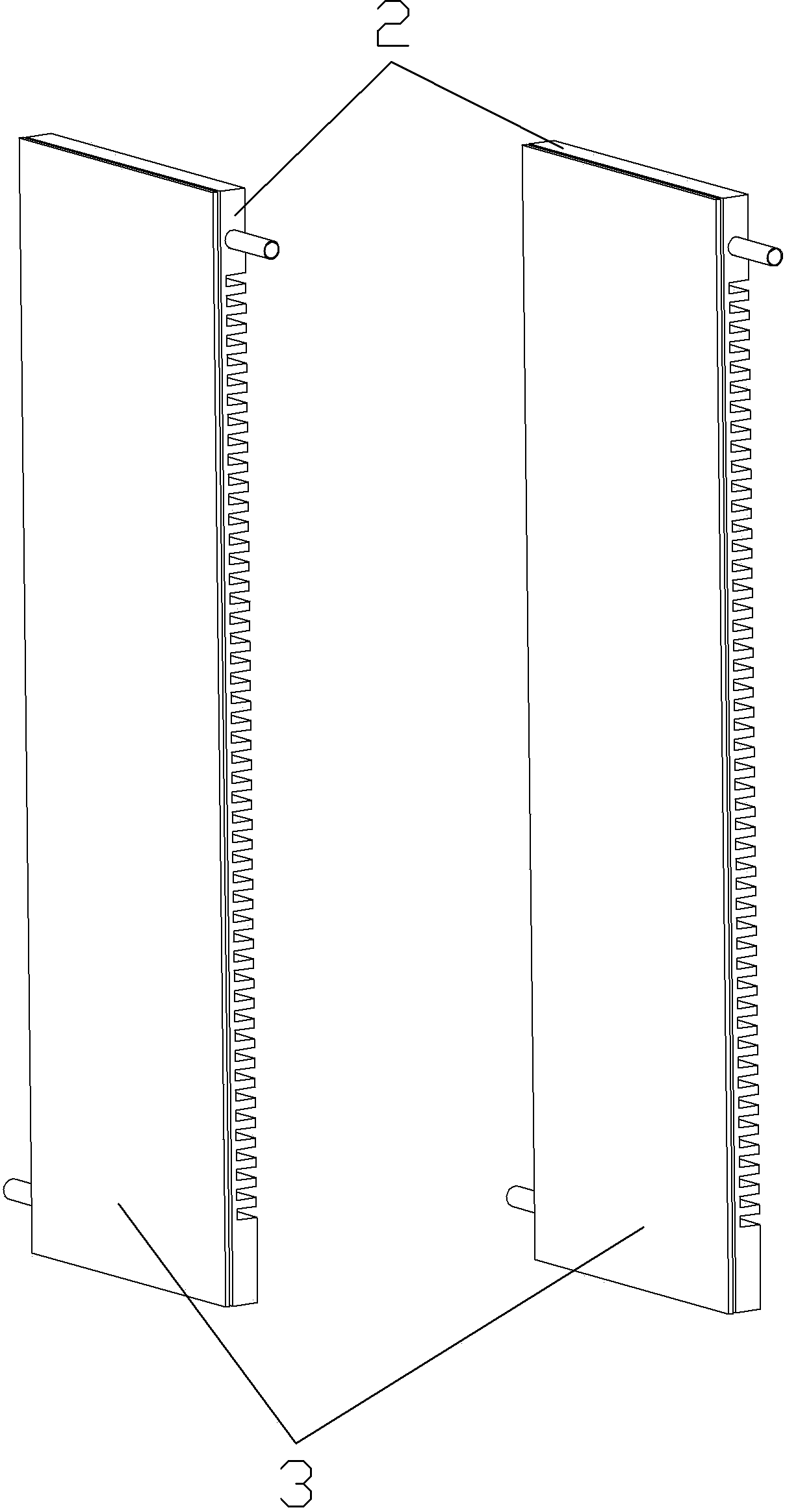

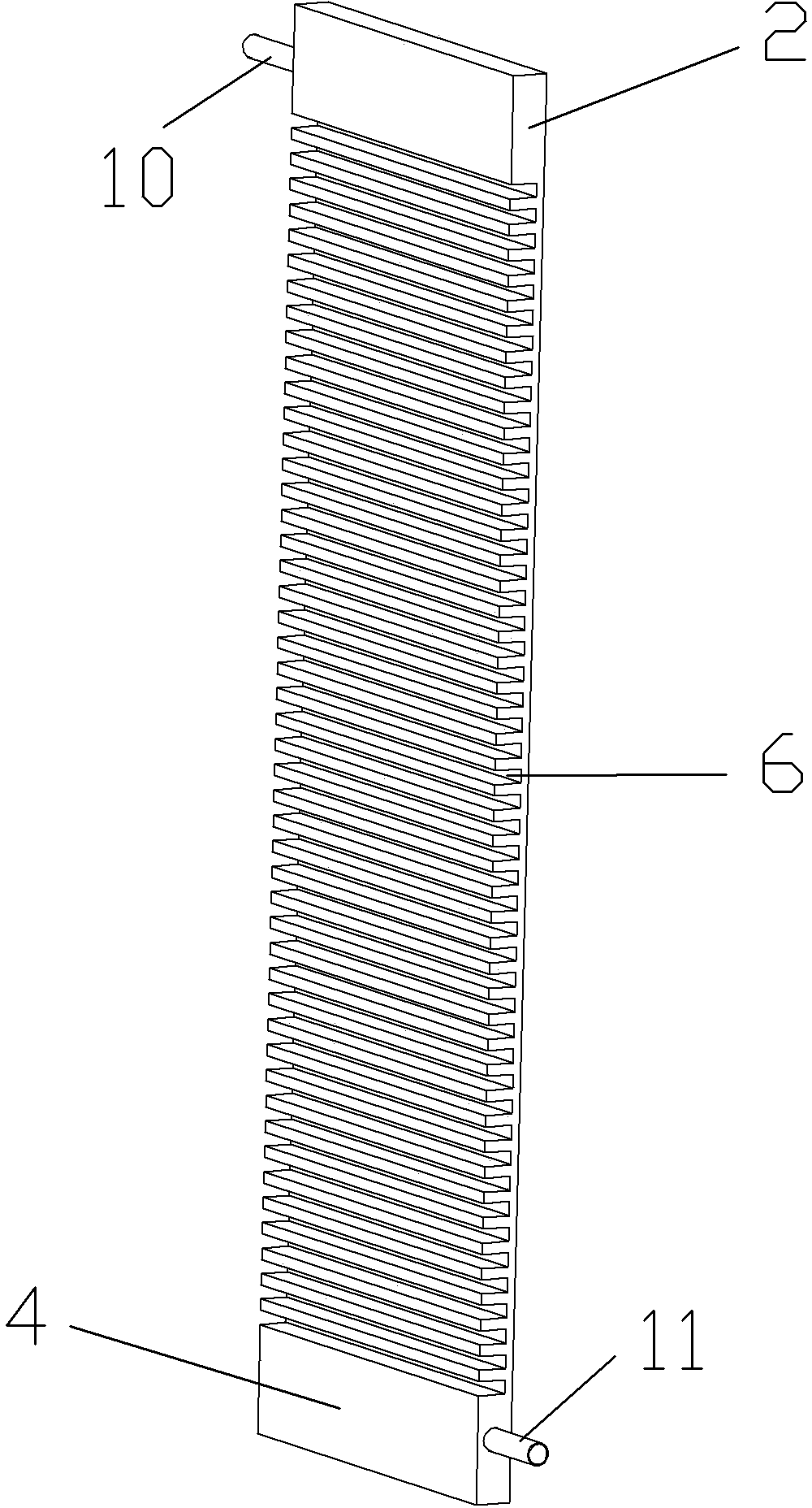

[0037] When the bipolar plate membrane electrode assembly is used in an air-cooled fuel cell stack, see figure 1 , figure 2 , image 3: The two ends of the anode surface 5 are respectively provided with gas-collecting grooves, the gas-collecting grooves are the gas-inlet gas-gathering groove 7 and the gas-gas-gathering groove 8 respectively, and the air pipes are specifically the hydrogen gas inlet pipe 10 and the hydrogen gas outlet pipe 11 , the hydrogen gas inlet pipe 10 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com