Fairlead mounting method for high teleseme

An installation method and signaling technology, applied in the direction of electrical components, can solve problems such as potential safety hazards, and achieve the effects of ensuring project quality, saving labor, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiment

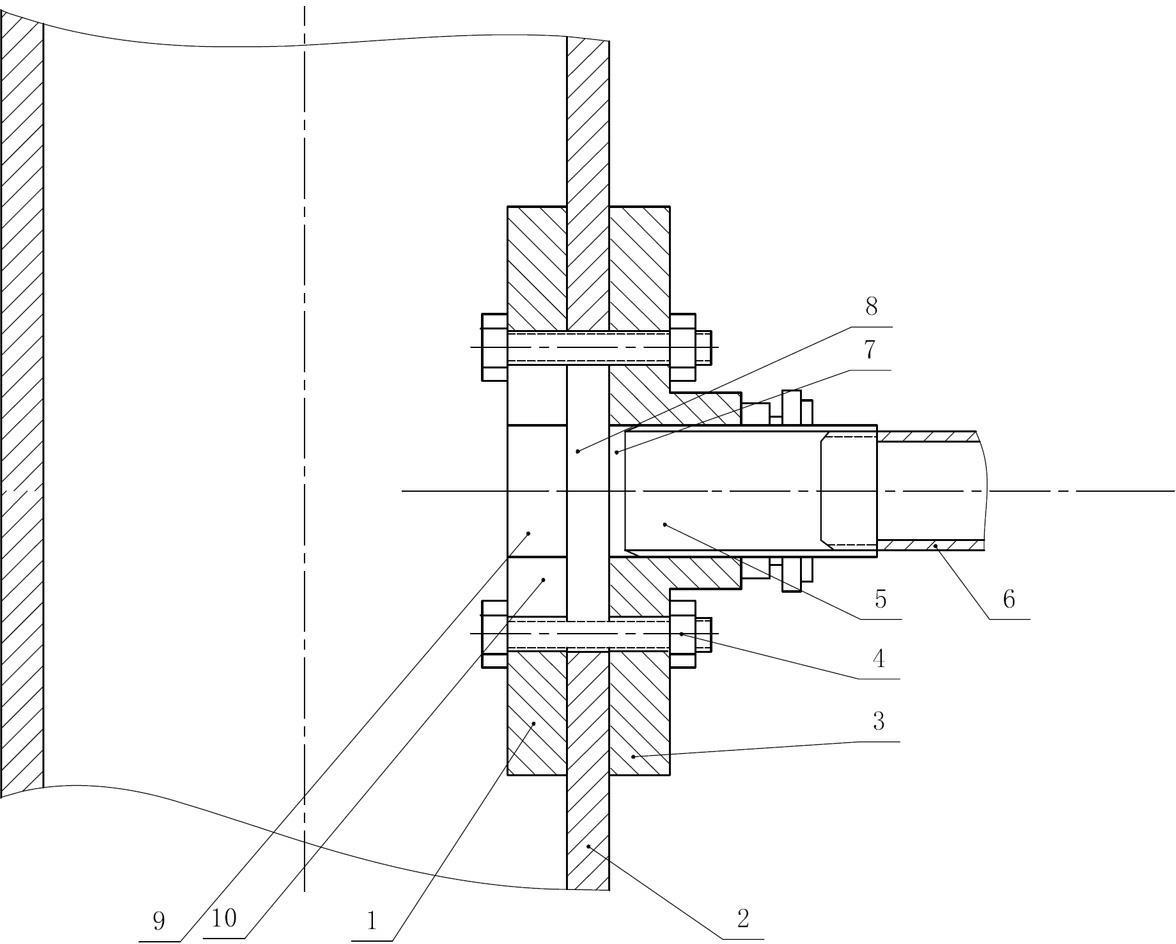

[0024] like figure 1 , figure 2 , image 3 As shown, the installation method of the high column signal machine lead pipe of the present invention comprises the following steps:

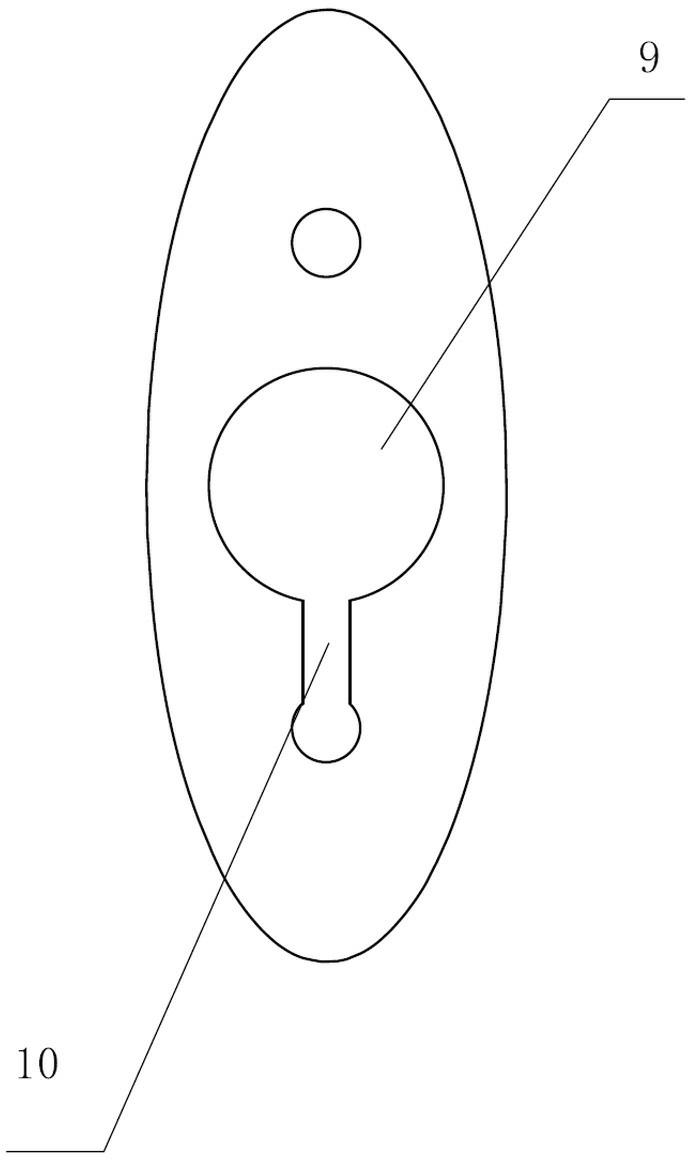

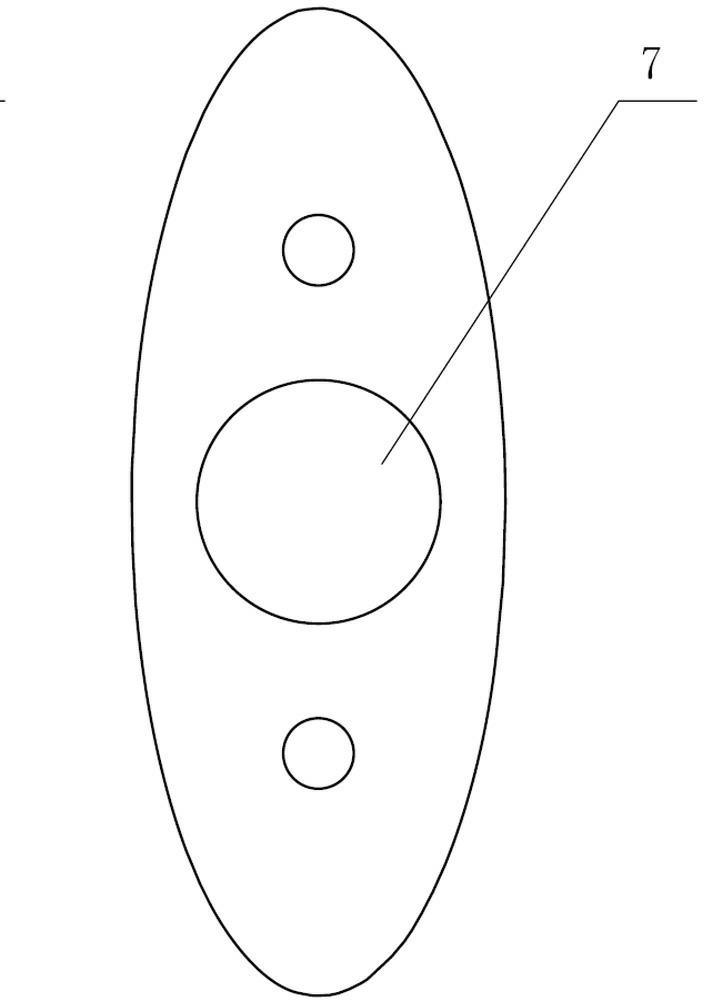

[0025] (1) Make and install the first flange 3 outside the reserved hole of the machine column and at the reserved hole of the XB box: see figure 1 , image 3 , the first flange 3 is an elliptical flange, the diameter of its minor axis is 1-1.5 cm smaller than the diameter of the reserved hole of the machine column; the diameter of its major axis is larger than the diameter of the reserved hole of the machine column; the surface of the flange is A first central through hole 7 is provided, and an internal thread is formed in the central through hole; two fixing holes 11 are formed on both sides of the central through hole along the long axis of the flange, and the distance between the two fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com