Adiabatic compressed air energy storage system with multi-stage thermal energy storage

A technology for compressing air and compressor systems, applied in the direction of engine functions, gas turbine devices, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

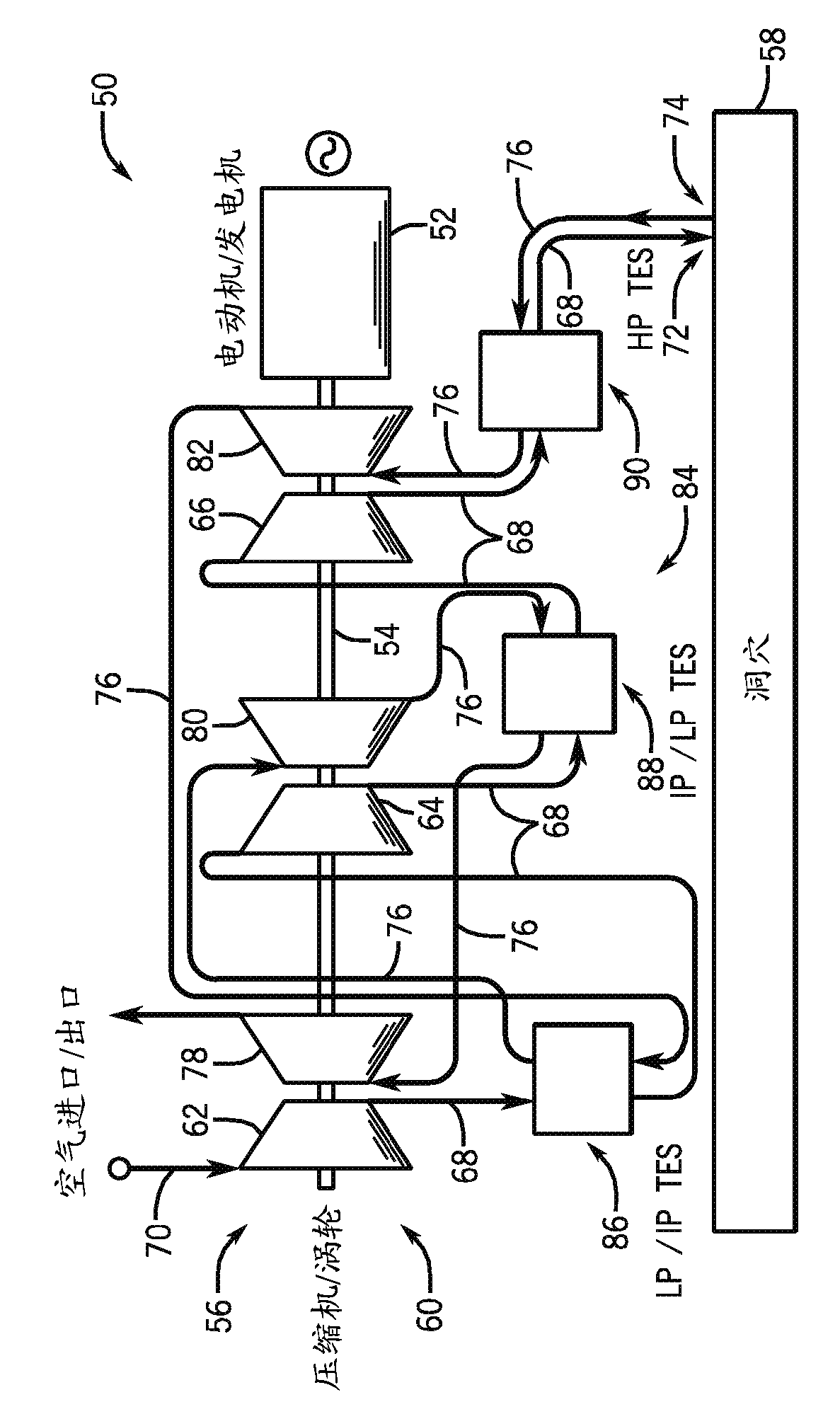

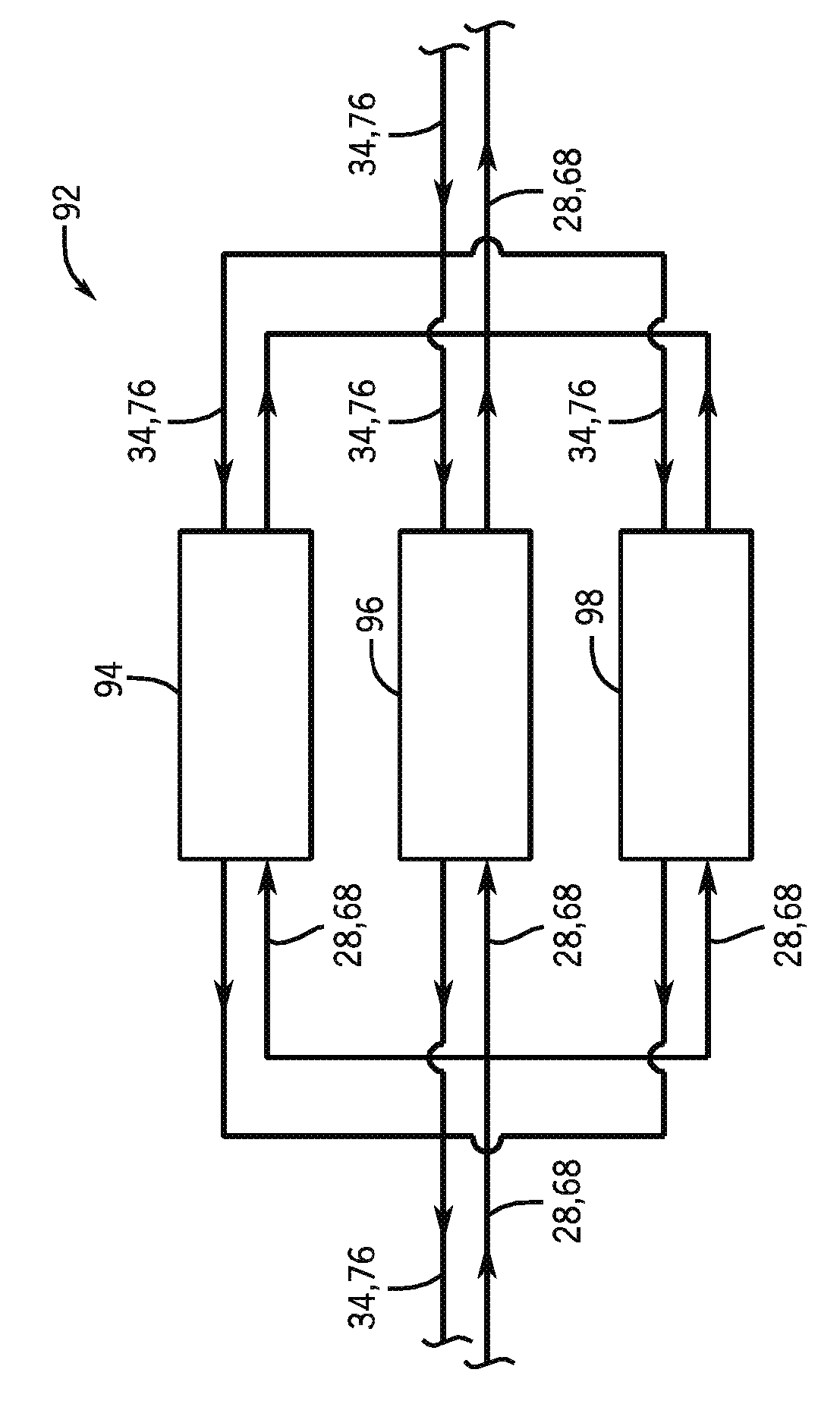

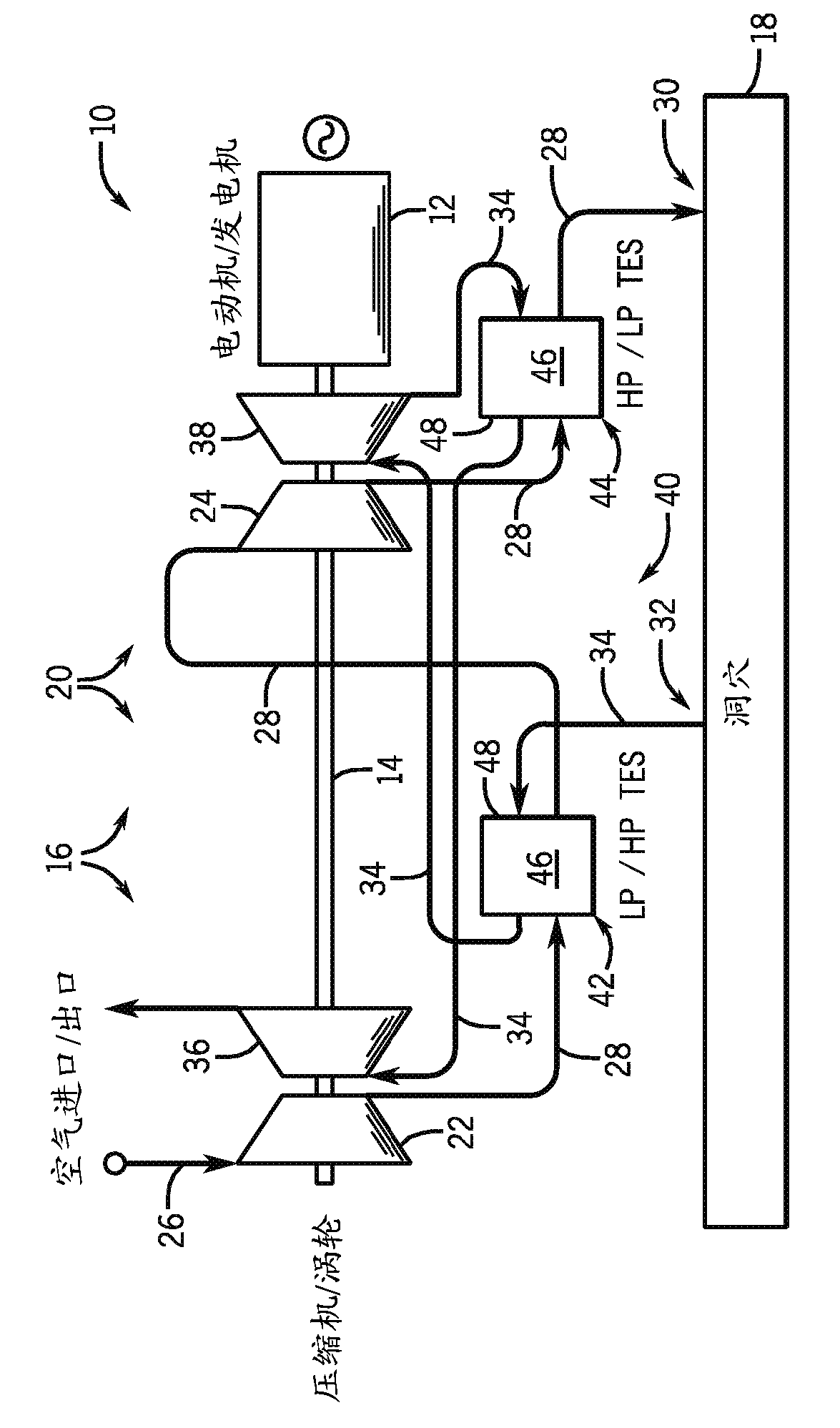

[0019] According to an embodiment of the present invention, a multi-stage thermal energy storage (TES) system is provided to cool and heat air in an adiabatic compressed air energy storage (ACAES) system. A multi-stage TES system includes multiple TES units whose operating states can be switched or reversed between operation of the ACAES system in compression mode and expansion mode.

[0020] refer to figure 1 , shows a block schematic diagram of an adiabatic compressed air energy storage (ACAES) system 10 according to one embodiment of the present invention. ACAES system 10 includes motor-generator unit 12 (which may be a combined unit or separate unit), drive shaft 14 , compression system or group 16 , compressed air storage space or cavern 18 , and turbine system or group 20 .

[0021] The motor-generator unit 12 is electrically connected to, for example, a base load power generation device (not shown) to receive power therefrom. Motor-generator unit 12 and drive shaft 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com