Micro multi-component glue head body

A gluing head, multi-component technology, applied in the device and coating direction of coating liquid on the surface, can solve the problems of low work efficiency, long curing time, constraints, etc., save energy, reduce downtime to clean gluing head The effect of body problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

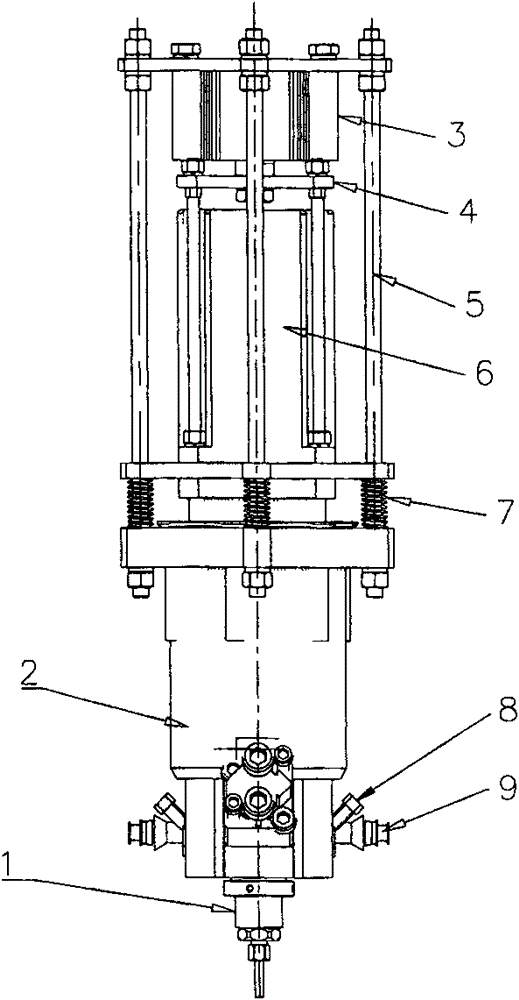

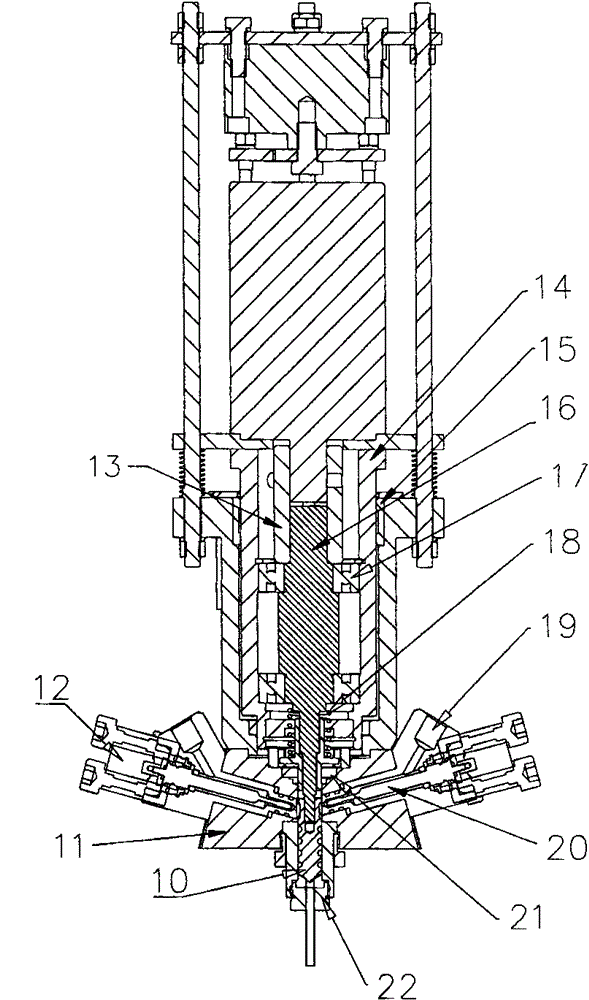

[0019] [specific example] such as figure 1 Shown, a kind of trace multi-component gluing head body comprises gluing head body 2, and gluing head body 2 is provided with the mixing cup 1 of valve 12, nozzle 22 and feed inlet 19 lower ends, the mixing of mixing cup 1 A stirring device is arranged in the chamber 11 , and two or more independent valves 12 installed with valve needles 20 are arranged on the glue applicator body 2 . The tip of the valve needle 20 of the above-mentioned valve 12 is directly against the outlet of the valve body end, and the other end of the valve needle 20 is connected with the cylinder 3, and when the cylinder 3 is pushed forward, the valve needle 20 is driven to close the outlet of the valve 12, and vice versa. In this way, the precise control of the amount of material injected into the mixing cup 1 is realized, which is beneficial to the control of slight changes in the material.

[0020] Two or more metering pumps controlled by a computer respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com