Tool wear condition monitoring method based on conditional random field model

A technology with random field conditions and tool wear, which is applied in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as wasting time, reducing workpiece processing accuracy, and reducing processing efficiency, and achieves easy signal acquisition and responsiveness Fast, sensitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments.

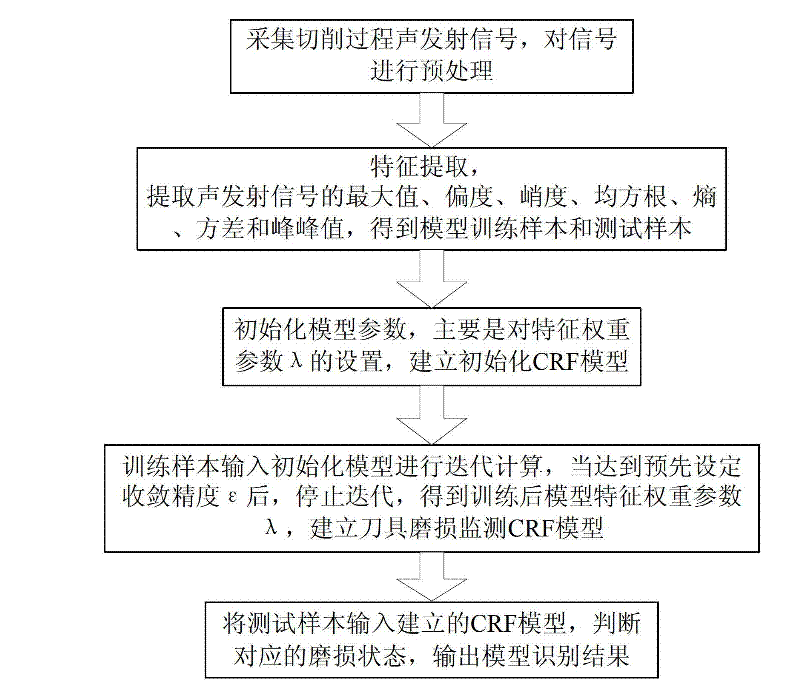

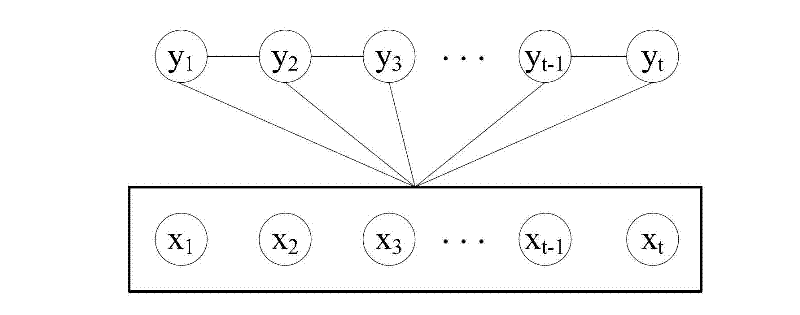

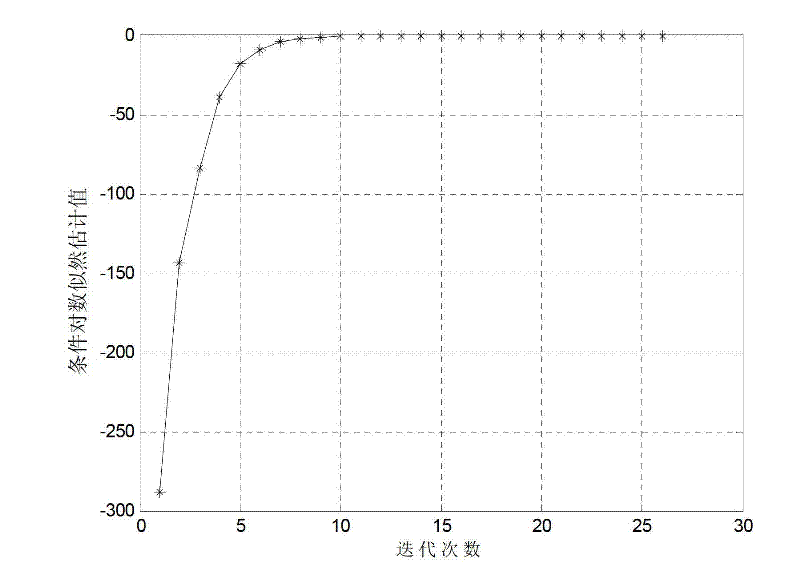

[0024] Such as figure 1 As shown, the tool wear state monitoring method based on the conditional random field (CRF) model of the present invention collects the acoustic emission signal during the cutting process, and performs preprocessing and related feature extraction on it, and uses the extracted feature vector as the conditional random The training samples and test samples of the airport model are used to establish a conditional random field model for tool wear monitoring. The test samples are input to the established model, and the corresponding wear conditions are output. The different wear conditions of the tools are accurately measured. Detection, to achieve the purpose of predicting the wear state of the tool only by analyzing the acoustic emission signal generated during the cutting process.

[0025] The present invention is a method for monitoring tool wear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com