An intelligent detection method for high-speed turnout crack damage based on vibration signal fusion

A vibration signal and intelligent detection technology, which is applied in the processing of detection response signals, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of large data volume, difficult processing, sensor influence, and difficult identification, and achieve suppression of modal mixing. Overlapping problem and the effect of simple signal acquisition and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

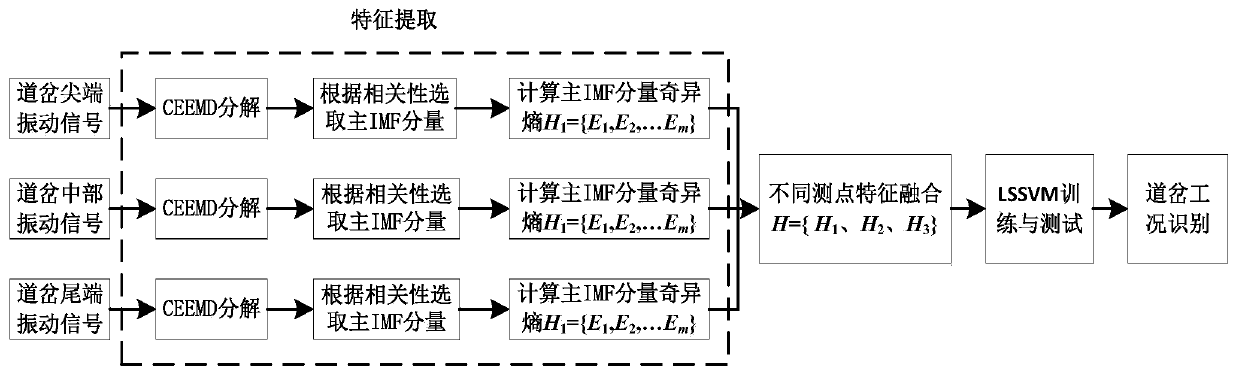

[0049] Such as figure 1 As shown, the specific embodiment of the present invention is, a kind of high-speed switch crack damage intelligent detection method based on vibration signal, and its steps are:

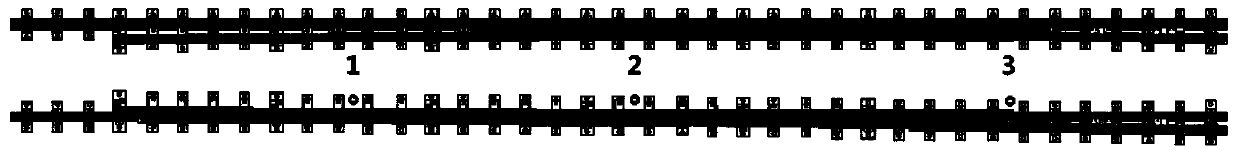

[0050] (1) According to the change law of the mode shape of the single-span simply supported beam of the turnout, the vibration acceleration sensor is installed at the three measuring points of the tip, middle and tail of the high-speed turnout;

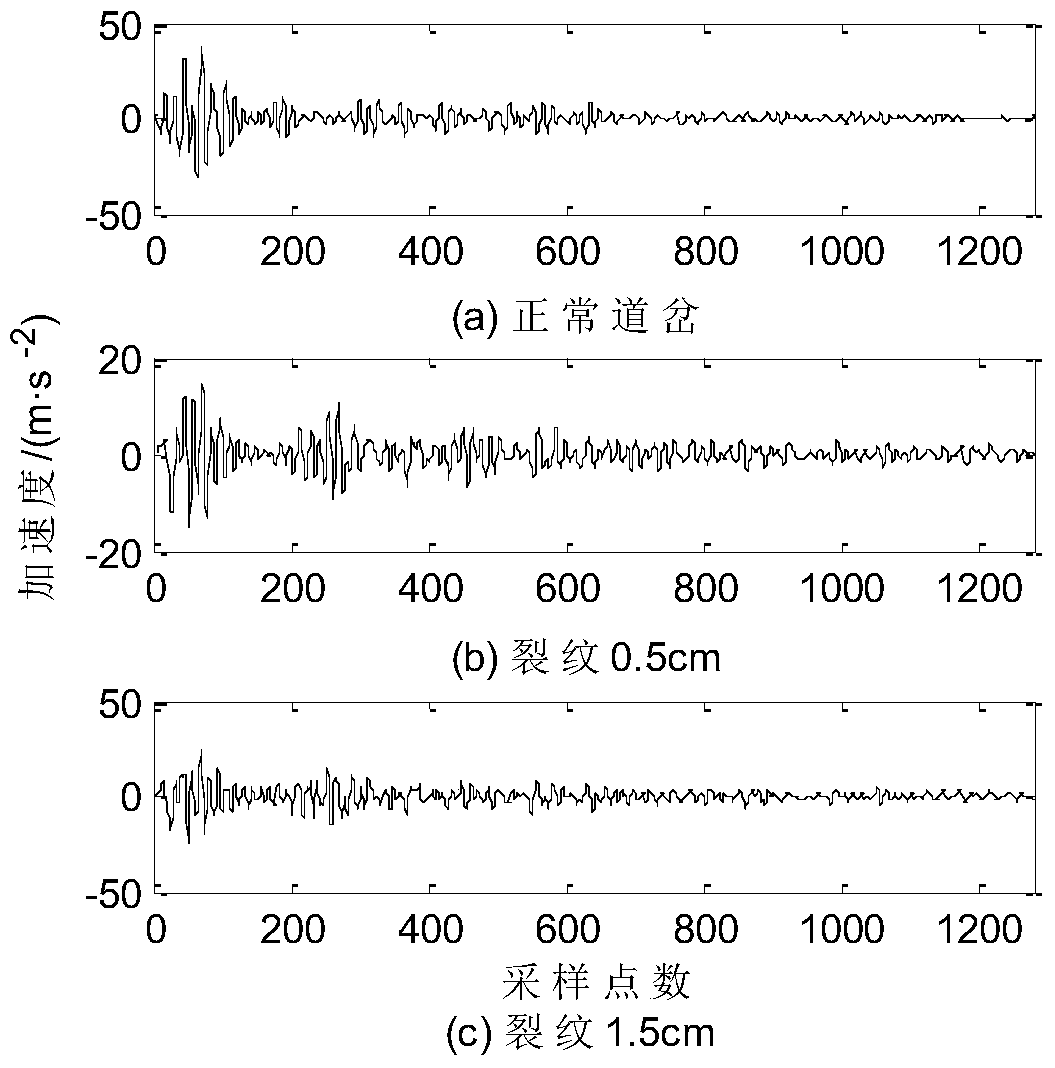

[0051] (2) When the train passes the turnout, the vibration signals of the turnout at the three measuring points are collected respectively. Without loss of generality, the vibration signal at the measuring point of the fork tip is x(i), i=1,...,N, where N is the number of sampling points.

[0052] (3) Adaptively decompose x(i) by using the Complete Ensemble Empirical Mode Decomposition (CEEMD), and obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com